Members of Energy I-Corps Cohort 4

Training for Energy I-Corps Cohort 4 was held Oct. 18–Dec. 8, 2016, in Golden, Colorado.

Cohort 4 was composed of 15 teams from Idaho National Laboratory (INL), Lawrence Livermore National Laboratory (LLNL), Los Alamos National Laboratory (LANL), National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), Oak Ridge National Laboratory (ORNL), and Sandia National Laboratory (SNL).

See photos of Energy I-Corps Cohort 4 and their graduation on our Flickr stream.

Teams and Technologies

Team Members

- Principal Investigator: Scott Jenne

- Entrepreneurial Lead: Jason Cotrell

- Industry Mentor: Sandy Butterfield

Technology Description

Autonomous Concrete Printing uses demonstrated concrete 3D printing technologies in a novel configuration to manufacture ultra-tall wind turbine towers in place. This technology is intended to print complex concrete structures without the need for additional support structures. In the envisioned embodiment, the technology will be able to print towers in heights that exceed 200m using low-cost materials and structurally efficient designs not possible using traditional manufacturing techniques.

Team Members

- Principal Investigator: Kevin Gering

- Entrepreneurial Lead: Josh McNally

- Industry Mentor: Frank Meijers

Technology Description

INL's CellSage is an advanced research and development software tool that closes the gap in understanding how to monitor and manage complex battery systems. It provides a means toward more comprehensive battery characterization as well as diagnostics and prognostics of aging mechanisms. CellSage provides information that can be used to optimize battery design and usage, and aids in the development of battery management schemes variable combinations of operating conditions and environments.

Team Members

- Principal Investigator: Guillaume Petitpas

- Entrepreneurial Lead: Ryan Zarkesh

- Industry Mentors: Herie Soto, Tobias Brunner

Technology Description

Hydrogen offers a wide variety of benefits to today's challenges for carbonless transportation (zero tail pipe emissions, rapid refueling, and long driving range) but its widespread commercialization is still limited due to high costs. Cryo-compressed hydrogen brings in unique cost-effective and compact technologies along the entire transportation pathway—delivery, dispensing and vehicle storage—that would make carbonless transportation a practical reality.

Team Members

- Principal Investigator: Troy Unruh

- Entrepreneurial Lead: Gregory Lancaster

- Industry Mentor: Sontra Yim

Technology Description

This effort will provide a nuclear-focused strategy for providing an advanced, innovative, and intuitive imaging technology to workers at nuclear facilities called Change Detection System (CDS). When deployed for nuclear applications, CDS will transform the way work is accomplished by leveraging powerful computer vision techniques for the identification and analysis of objects/areas not currently available to the nuclear reactor community. CDS has received two patents and two R&D 100 Awards.

Team Members

- Principal Investigator: Ahmad Al Rashdan

- Entrepreneurial Lead: Carson McNair

- Industry Mentor: John Kessler

Technology Description

The proposed technology is to enable online performance monitoring of vented dry casks by installing a device on all air vents to monitor the physical parameters of air such as temperature, flow rate, density, nuclear radiation, impurities, humidity, salt content, acidity, and chemistry, and to apply a method that is based on accumulating measurements then correlating accumulated measurements to dry-cask failure baselines or signatures.

Team Members

- Principal Investigator: Tedd Lister

- Entrepreneurial Leada: Luis Diaz Aldana, Leslie Ovard

- Industry Mentor: Jon Cook

Technology Description

Electrochemically Recycling Electronic Components of Value (E-RECOV) is novel technology developed specifically to reclaim valuable metals from discarded electronic equipment. The process uses an electrochemical cell to efficiently recover the bulk of metals, leading to more thorough recycling of materials while significantly minimizing chemical use and waste generation. The process is sustainable, safe, and environmentally friendly and can be accomplished domestically and economically.

Team Members

- Principal Investigator: Andrew Sutton

- Entrepreneurial Lead: Cameron Moore

- Industry Mentor: David Thorne

Technology Description

By using small bioderived molecular building blocks, we can synthesize several products—paint additives, chemical solvents, and chemical precursors—using a handful of simple chemical transformations. Because it is a single pathway, we can alter the reaction conditions to adjust the chemicals produced dependent on market demand. To increase robustness in our process, we can also produce diesel, gasoline, and jet components to tap into a limitless volume market in case of market saturation.

Team Members

- Principal Investigator: Chad Augustine

- Entrepreneurial Lead: Greg Stark

- Industry Mentor: Jim Corboy

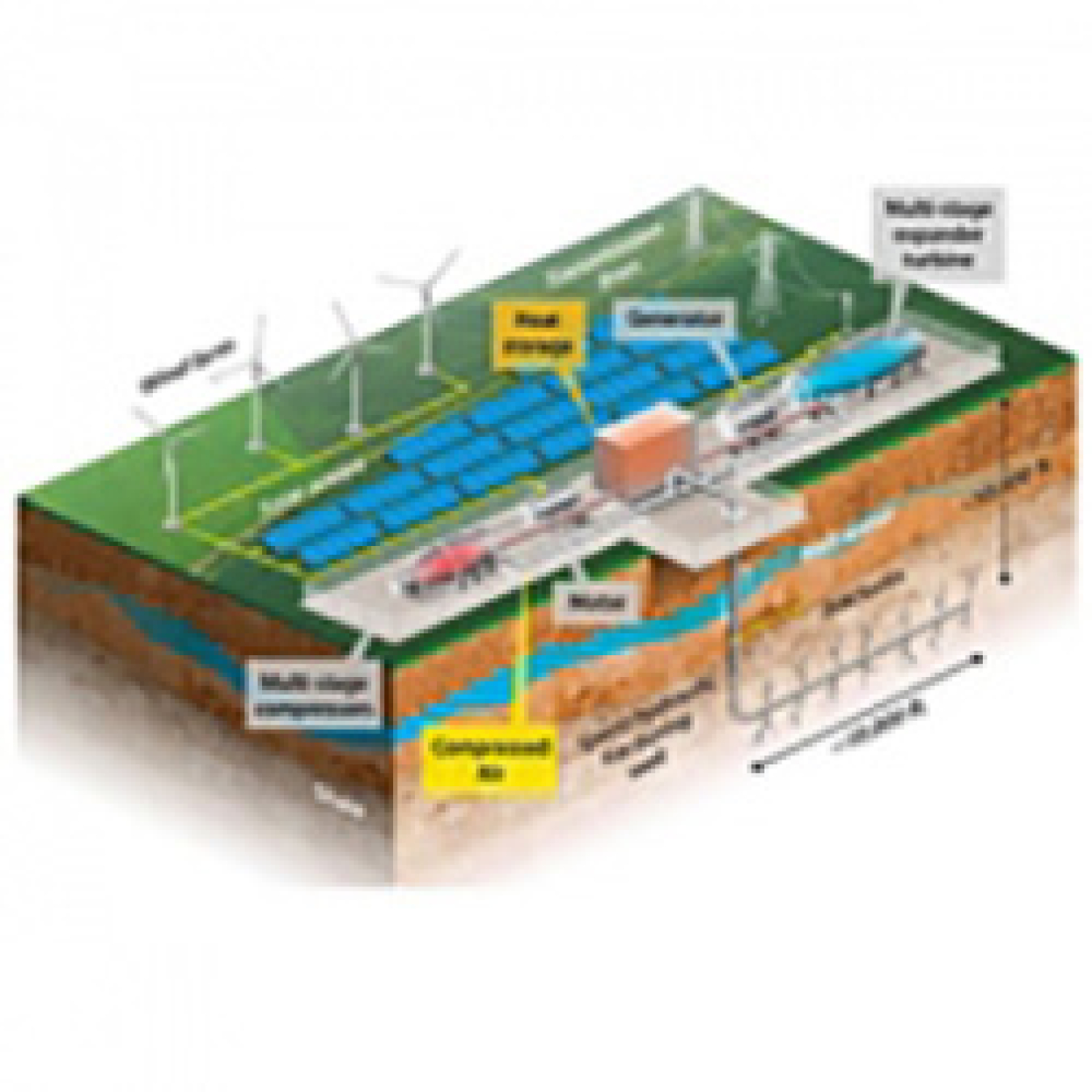

Technology Description

Compressed Air Energy Storage (CAES) uses compressors to store pressurized air during low-electricity demand periods and release it through turbines to generate electricity during high-electricity demand periods. CAES projects typically use underground salt domes for air storage, which limits suitable geographical locations. This novel technology aims to expand the geographical locations for CAES and lower its costs by repurposing depleted hydraulically fractured gas wells for air storage.

Team Members

- Principal Investigator: Aaron Ptak

- Entrepreneurial Lead: David Young

- Industry Mentor: Sally Hatcher

Technology Description

Team HALO will explore a business model for NREL's research on dynamic hydride vapor phase epitaxy (D-HVPE) to grow high efficiency III-V solar cells at a greatly reduced price compared with the incumbent technology of metal organic chemical vapor deposition (MOCVD). D-HVPE produces devices with excellent bulk material quality and sharp, well-passivated interfaces at high deposition rates (>1 µm/min) using low-cost bulk metal and HALOgen chemistry.

Team Members

- Principal Investigator: Lelia Cosimbescu

- Entrepreneurial Lead: Karl Albrecht

- Industry Mentor: Tony Christensen

Technology Description

Lubricant Engineers has been developing multi-branched and hyper-branched polymers that have shown promise as viscosity index improvers and friction reducers. Hyper-branched polymers are previously unreported for this application but are believed to be more resistant against shear degradation versus their linear counterparts. Homo-polymers of lipophilic monomers were prepared and in some cases polar co-monomers were introduced in the design for friction control.

Team Members

- Principal Investigator: Congwang Ye

- Entrepreneurial Lead: Lionel Keene

- Industry Mentor: Gerry Baranano

Technology Description

As CO2 emission continues to impact our global environment, more effective approaches to capture CO2 are desired. To this goal, we developed micro-encapsulated CO2 sorbents (MECS) with microfluidic processing. These mechanically robust microcapsules are not only safer to use in many unprecedented scenarios but also captures CO2 more than three to 10 times faster than current CO2 removal technologies. The captured CO2 can then be released by heat or diffusion to obtain high-purity CO2 for reuse or storage.

Team Members

- Principal Investigator: Allison Ray

- Entrepreneurial Lead: Hong Hu

- Industry Mentor: Ryan Bills

Technology Description

Researchers at INL are developing a solution to enable a blended feedstock strategy in the production of renewable fuels. The use of blended feedstocks addresses several challenges in the current supply chain including availability, cost, quality, and variability. Blending provides a mechanism to reduce supply chain risk and may reduce feedstock costs by as much as 30%. Preliminary results suggest blending provides a low-cost, consistent biomass supply for advanced bio-fuel production.

Team Members

- Principal Investigator: Daniel Deng

- Entrepreneurial Lead: Lara Aston

- Industry Mentors: Paul Jacobson, Sara Hunt

Technology Description

A smaller RF tag with increased tag life that could be implanted by injection instead of by surgery would substantially overcome present constraints thereby broadening the application range of RF tag. Besides being used to study the survival of small fish through hydroelectric dams, it would permit tracking of most bats and small birds currently not possible using presently available active tags and could provide a breakthrough to understanding interaction between wind turbines and bats.

Team Members

- Principal Investigators: Paco Maldonado, Scott Lindbolm

- Entrepreneurial Lead: David Sais

- Industry Mentor: Todd Hunter

Technology Description

Harsh environments prove to be a limiting factor for standard electronics. Utilizing advanced electronics and packaging techniques, we are able to develop rugged electronics systems that can withstand the punishing conditions they must operate in.

Team Members

- Principal Investigator: Kyle Glusenkamp

- Entrepreneurial Lead: Ahmad Abu-Heiba

- Industry Mentor: Guolian Wu

Technology Description

The majority of U.S. homes contain an electric clothes dryer, and these appliances account for about 6% of residential energy consumption. Thermoelectric Dryer has been developing a ventless dryer using thermoelectric heat pump can reduce energy consumption by about 40% while being less expensive to purchase than the existing vapor compression-based heat pump dryers on the market.