One of NNSA’s core missions is to ensure the United States maintains a safe, secure, and reliable nuclear stockpile. These weapons—along with the submarines, ballistic missiles, and aircraft that deliver them—constitute the nation’s strategic deterrent. For more than 75 years the nuclear deterrent has underpinned America’s security, deterring our adversaries, reassuring our allies and partners, and promoting global stability.

The Office of Defense Programs is responsible for maintaining and modernizing the stockpile. Our engineers and technicians ensure the health of the weapons by studying and replacing components and materials as they age. Scientists conduct experiments using some of the most advanced facilities in the world to enhance our understanding of weapon performance. Production facilities manufacture the thousands of materials and components that comprise modern nuclear weapons, assuring their long-term reliability.

The deterioration of the global security environment has made clear that nuclear deterrence will remain a prominent feature of the international landscape for decades. As the United States confronts the unprecedented challenge of deterring two nuclear peers, the age of our stockpile requires an intensive modernization program. Likewise, our infrastructure has atrophied since the Cold War and must be recapitalized. As we revitalize our facilities and infrastructure, NNSA is building a responsive complex with modern technology, allowing us to adapt to changing requirements driven by shifting world conditions.

The transparency NNSA provides regarding our Nuclear Security Enterprise is unique among the world’s nuclear weapon states. Details about nuclear weapons, the deterrence mission, and NNSA’s management of the stockpile can be found in the current Stockpile Stewardship and Management Plan and the Nuclear Matters Handbook.

At NNSA we are applying the power of science not simply to enhance U.S. security but in pursuit of a more peaceful, prosperous, and stable world.

The Post-Cold War Stockpile

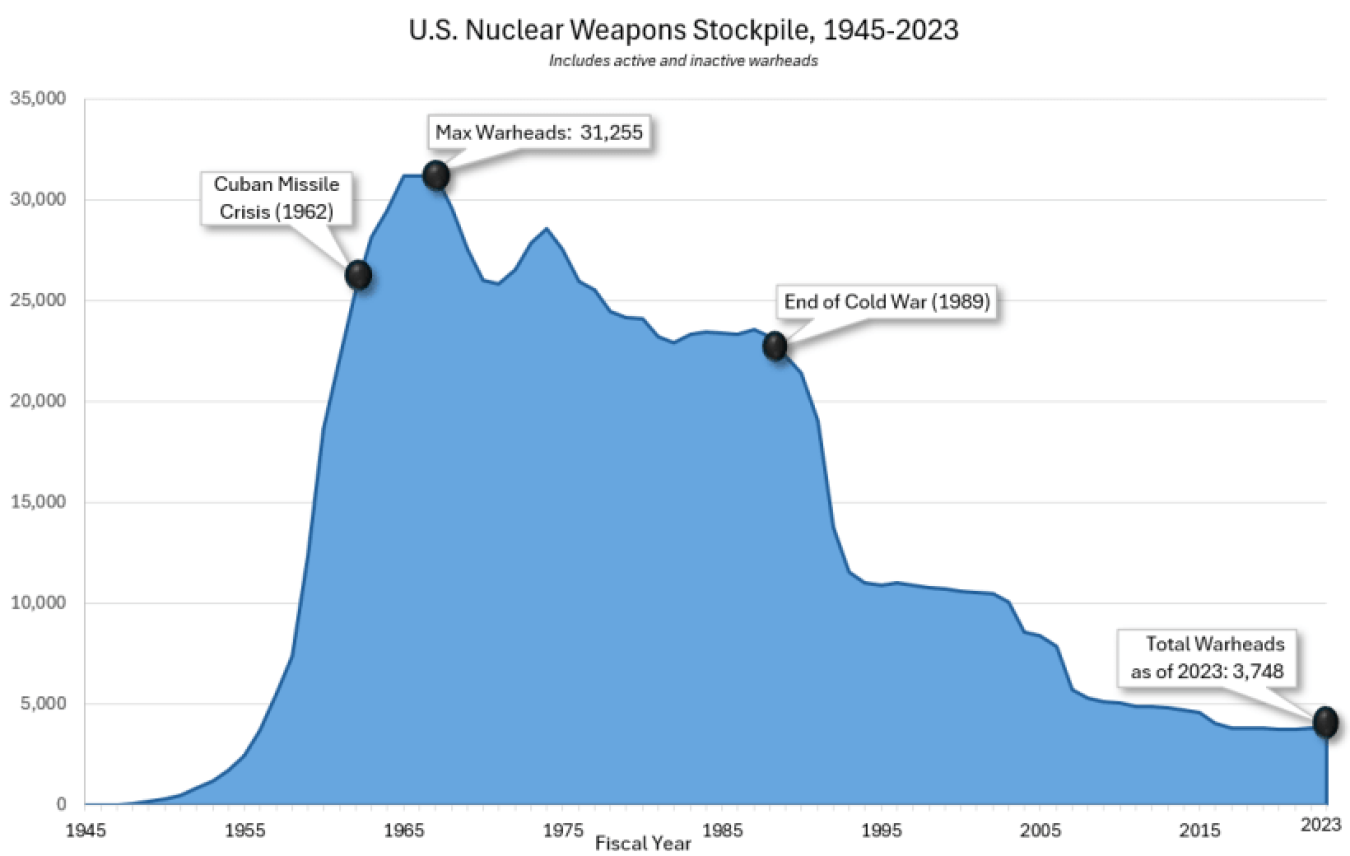

The U.S. nuclear stockpile is the smallest it has been since 1960. As of 2023, the stockpile stood at 3,748 warheads—a roughly 88 percent reduction in size since its peak of 31,255 warheads in the late 1960s. Most weapons in the current stockpile were produced during the 1970s and 1980s. At the time they were built, these weapons were not designed or intended to last indefinitely.

As a result of the voluntary moratorium on nuclear explosive testing the United States has observed since 1992, NNSA now ensures the reliability of the nation’s nuclear weapons through the Stockpile Stewardship Program. Comprising a wide range of scientific activities, from modeling and simulation to subcritical nuclear experiments, this program allows us to assess and certify the stockpile with extraordinary confidence.

Nevertheless, maintaining the stockpile today is much more difficult than during the Cold War. In addition to designing, manufacturing, and sustaining weapons without nuclear explosive testing, we must accommodate arms control verification in our production processes and exercise care for the workforce and environment in every phase of the weapon lifecycle. Meeting these challenges depends on the unparalleled ingenuity and resourcefulness of NNSA’s Nuclear Security Enterprise.

Composed of a nationwide network of national laboratories and production facilities and more than 65,000 nuclear security professionals, the enterprise conducts the research, development, testing, and production needed to deliver the nuclear stockpile to the U.S. military.

NNSA shares responsibility for the nuclear deterrent with the Department of Defense (DoD). Senior leaders from NNSA and DoD sit on the Nuclear Weapons Council, a forum for reaching consensus and establishing priorities relating to the quantity and characteristics of the weapons fielded to ensure U.S. national security.

Stockpile Management

Nuclear deterrence has been the cornerstone of U.S. national security for more than 75 years, allowing us to preserve our way of life without fighting major wars. To succeed, deterrence requires our adversaries to understand that the costs of aggression against the United States or its allies and partners will always outweigh any conceivable benefits. The credibility of this guarantee requires a nuclear stockpile that is unfailingly reliable and effective.

NNSA’s Stockpile Management Program encompasses the full range of a weapon’s lifecycle, from design and development to production and maintenance and ultimately to dismantlement and disassembly. Each weapon type requires routine maintenance, repair, replacement of limited life components, surveillance (the thorough examination of a weapon), and other activities to ensure their safety, security, effectiveness, and reliability.

In the current stockpile, the average duration since a warhead was manufactured or refurbished is roughly 28 years. Over the next two decades, the stockpile will be sustained and modernized through vigorous surveillance, assessment, life extension, modification, acquisition, and dismantlement efforts. NNSA delivered more than 200 modernized weapons to the DoD in 2023 alone—the most since the end of the Cold War—and comparable demand is expected over the next decade and beyond.

Our scientists and engineers provide assurance that the United States can deliver militarily effective weapons. As we work with the DoD to evaluate the needs of the deterrent, NNSA will deliver new capabilities to fill deterrence gaps. NNSA is also undertaking transformative initiatives to protect against adversary subversion of nuclear weapons and associated capabilities.

Together we supply the crucial ingredient needed for deterrence to succeed—our adversaries’ recognition that U.S. threats to retaliate swiftly and decisively against any strategic attack on the United States or its allies are backed by indisputable nuclear capabilities.

A critical NNSA mission is to sustain the current U.S. nuclear stockpile and certify that it remains safe, secure, effective, and reliable without nuclear explosive testing. Stockpile sustainment activities include surveillance, assessment, maintenance, and capabilities development.

In support of the annual stockpile assessment process, NNSA conducts surveillance—the careful scrutiny of an individual warhead—to understand the current health of the stockpile and identify aging trends. We work with the DoD and its armed forces to exchange limited life components, such as gas transfer systems and neutron generators, to ensure the warheads’ continued operability.

NNSA and its national laboratories also partner with the DoD to conduct flight, system, laboratory, and component-level testing. Joint Test Assembly flight tests, where representative weapons without nuclear material are realistically tested with the missile or bomb that carries them, provide one of the most important data sources used in stockpile assessment. These tests provide confidence to U.S. leaders and demonstrate the credibility of the United States’ nuclear deterrent to our adversaries and allies alike.

As part of the warhead modernization process, NNSA safely dismantles and dispositions retired and legacy weapons and components. This process supports ongoing nonproliferation efforts while also ensuring that materials are safely held for reuse in support of stockpile modernization.

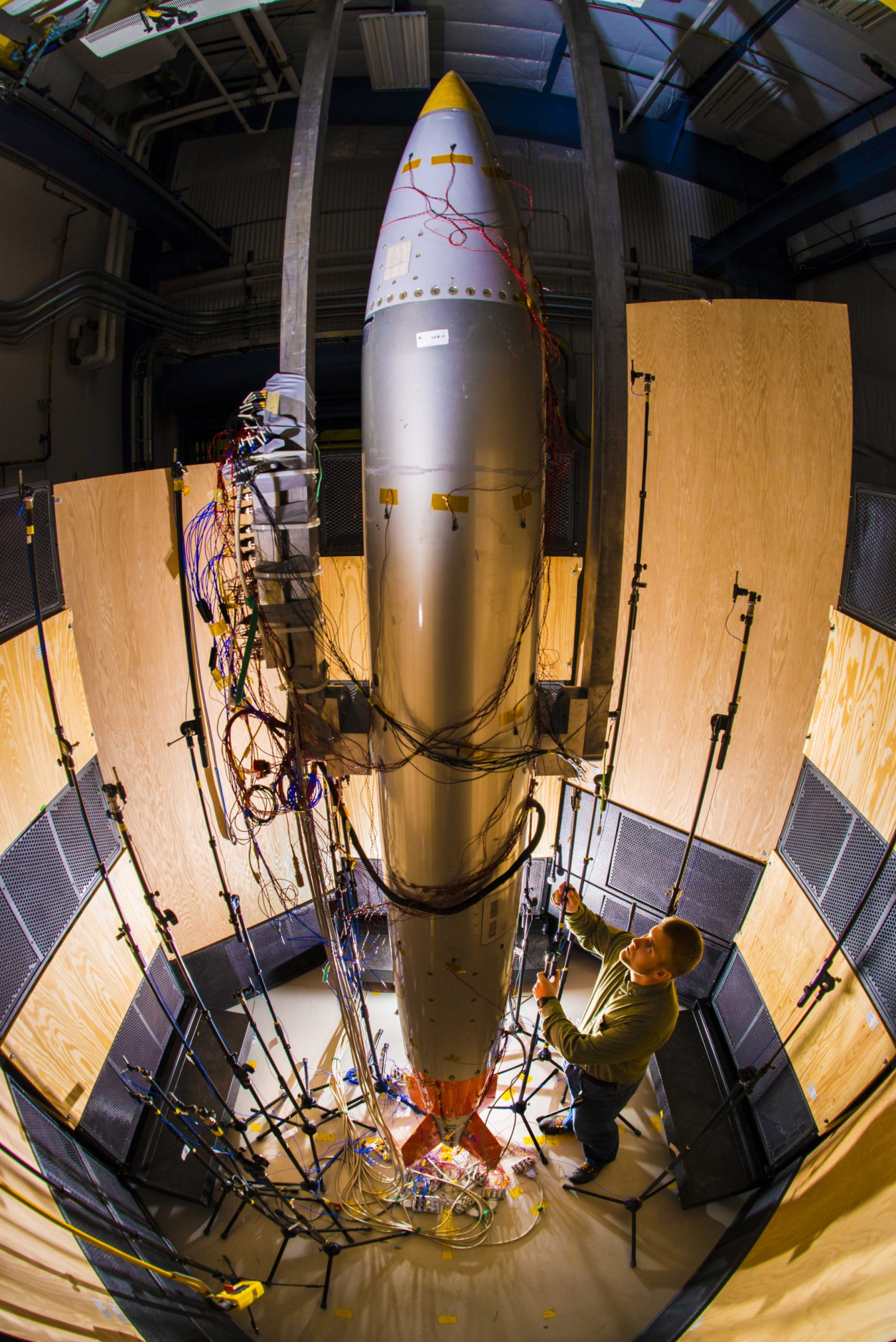

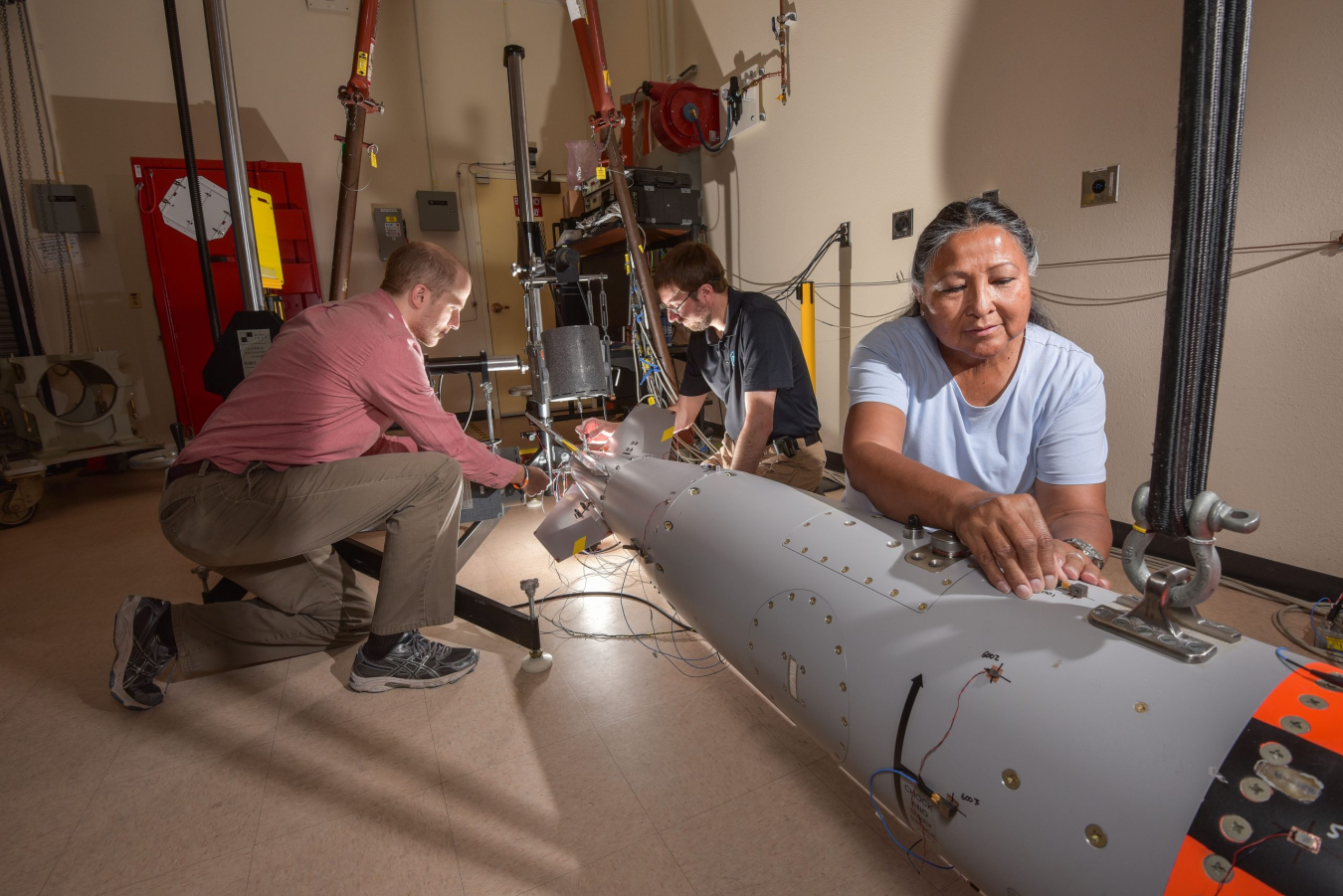

Workers at Sandia National Labs prepare a B61-12 for a vibration test.

Workers at Sandia National Labs prepare a B61-12 for a vibration test.As with any complex mechanical system, components in nuclear weapons degrade over time. Life extension programs enable NNSA to ensure the continued safety and reliability of weapons that have reached the end of their original design life. As part of this program, NNSA scientists and engineers comprehensively analyze all weapon components and determine whether to reuse, refurbish, or replace them. When complete, life extension programs resolve aging and performance issues, enhance safety features, and improve the security of the weapons.

NNSA also conducts alterations of weapons to ensure they remain safe, secure, and effective. An alteration is a limited-scope change that affects assembly, tests, maintenance, and/or storage of weapons. An alteration may address identified defects and component obsolescence; however, it does not change a weapon’s operational capabilities.

By contrast, modifications consist of changes to a stockpile weapon type’s operational capabilities. A modification might respond to new military requirements, enhance the margin against failure, increase safety, or improve security.

Finally, NNSA may undertake warhead acquisitions to meet military requirements that cannot be achieved by an existing stockpile warhead. New warheads are based on decades of accumulated knowledge derived from nuclear testing and advanced computer simulation and as such do not require nuclear explosive testing.

Active Modernization Programs

There are several major warhead modernization programs underway today, which are described in detail in the current Stockpile Stewardship and Management Plan. The Weapons Modernization fact sheets also provide a quick reference guide on these programs:

The Production Operations program provides the base capabilities that enable NNSA’s production mission in the form of skilled personnel at the national laboratories, plants, and sites. This mission, spanning warhead modernization, sustainment, and dismantlement and disposition programs, depends on professionals with expertise in engineering, manufacturing, quality assurance, and other critical disciplines. Production Operations ensures the necessary knowledge and tools are maintained for component manufacturing, weapon assembly and disassembly, maintenance, and production data management for all stockpile activities.

In addition to supporting NNSA’s stockpile mission, Production Operations supports the New Brunswick Laboratory (NBL) program office, which is essential to NNSA’s international safeguards and nonproliferation programs. By producing uranium, plutonium, and thorium reference materials, NBL enables the calibration of measurement equipment. For more information, visit the NBL program page here.

Nuclear Enterprise Assurance (NEA) is an enterprise-wide countersubversion program intended to prevent, detect, or mitigate the potential consequences of hostile subversion of U.S. nuclear weapons and weapon-enabling capabilities. Subversion entails a range of nefarious activities designed to degrade weapon reliability or performance. NEA manages subversion risks to the stockpile and its associated design, production, and testing capabilities. NEA experts evaluate credible extant and emerging threats and technological advancements, implementing countermeasures to ensure the integrity and reliability of the U.S. nuclear stockpile.

NEA activities cover the full nuclear weapon lifecycle, from development and sustainment to modernization and ultimately retirement.

NEA is responsible for protecting nuclear weapons-enabling capabilities, including: NEA addresses crosscutting functions across the nuclear security enterprise, such as: - Infrastructure (facilities, utilities, and workforce)

- Equipment, materials, and tools needed to support:

- Procurement

- Management

- R&D

- Design

- Production

- Testing

- Surveillance

- Maintenance

- Dismantlement

- Disposition of weapons and components

- Supply chain risk management

- Cybersecurity

- Information security

- Verification and acceptance

- Information management

- Logistics

- Physical security

- Quality assurance

Research, Development, Test, and Evaluation

Deterrence of America’s adversaries hinges on the credibility of our nuclear capabilities, and the very foundation of the U.S. nuclear deterrent is the scientific knowledge resident in and generated by the Nuclear Security Enterprise. Until 1992, the United States demonstrated the reliability of the stockpile in part through nuclear explosive tests. Since the end of nuclear explosives testing, NNSA has established credibility by operating state-of-the-art science facilities, where research and development, modeling of nuclear weapons performance, and computer simulations serve as substitutes for nuclear explosive tests.

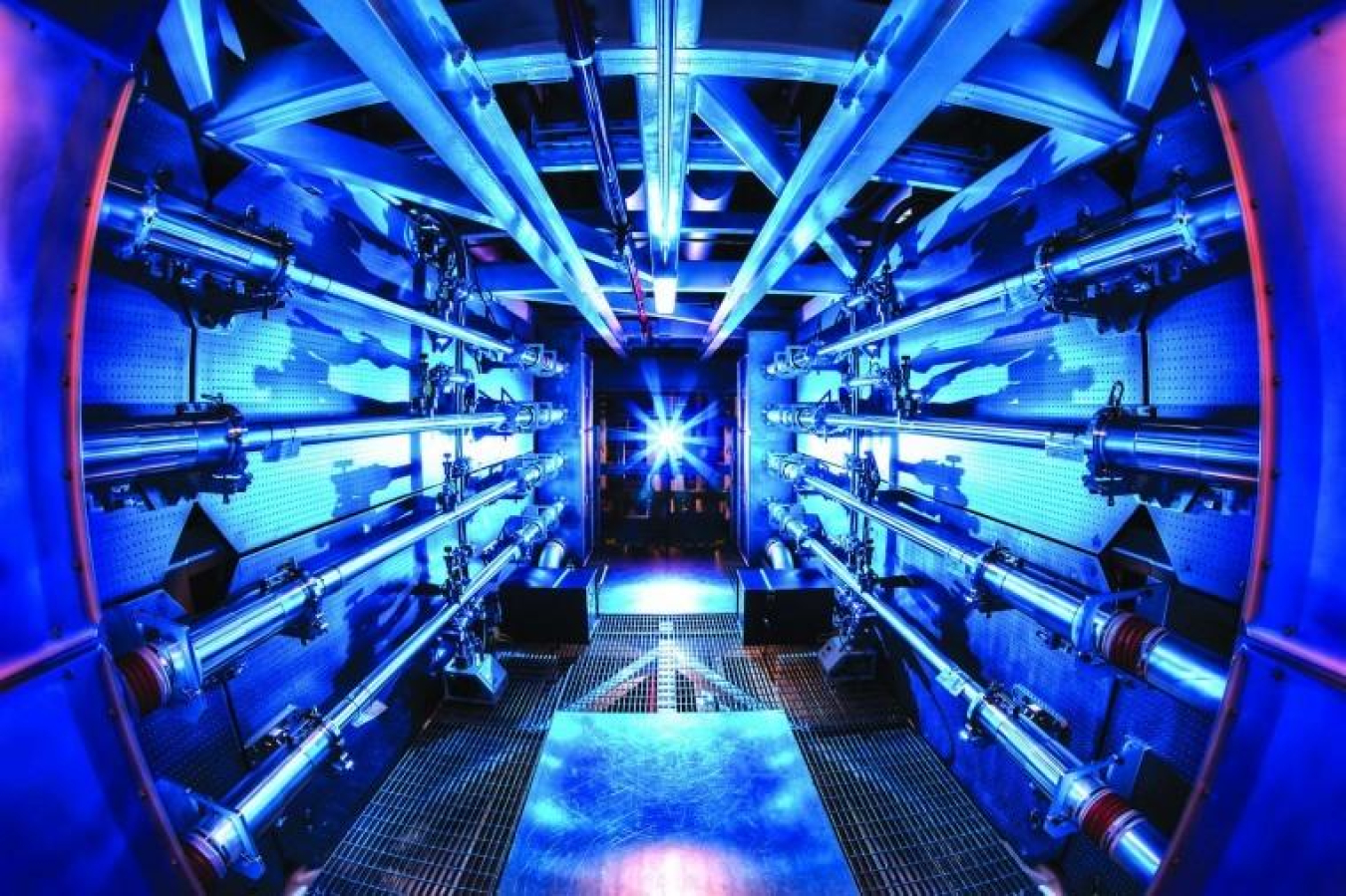

Nuclear fusion breakthroughs at the National Ignition Facility are advancing our understanding of the stockpile, deriving knowledge once accessible only through nuclear explosive tests. Our scientists are performing cutting-edge research on high-performance computers, including El Capitan, the world’s fastest exascale computing platform. Our modeling capabilities are being used to mitigate the effects of aging on the stockpile and design new systems.

In a turbulent and uncertain world, the scientists and engineers of the nuclear security enterprise are bolstering the reliability of the current stockpile even as they design and deploy new systems. Their scientific insights also identify novel technological threats, helping to defend the nation against technically advanced adversaries. At NNSA we are applying the power of science not simply to enhance U.S. security but in pursuit of a more peaceful, prosperous, and stable world.

To ensure all the components of our nuclear weapons will perform as needed, NNSA scientists and engineers study weapon materials to predict their behaviors in the extreme conditions of nuclear operations, including high-pressure, high-temperature, and high-strain environments. Additionally, we develop novel materials and advance revolutionary technologies to ensure the stockpile remains unquestionably safe and effective.

To ensure the reliability of our weapons without nuclear explosive testing, NNSA must assess the effects of aging and manufacturing processes on the stockpile. In hydrodynamic testing, non-fissile isotopes—which cannot sustain a neutron chain reaction—are subjected to enough pressure and shock that they start to behave like liquids, becoming hydrodynamic. While these experiments do not create nuclear yield, they provide vital data about what happens during a nuclear detonation. When combined with theory, modeling, simulation tools, and other focused experiments, hydrodynamic testing helps underwrite our confidence in the nuclear deterrent.

To capture what happens during these experiments, NNSA has made many advancements in radiographic sources and other advanced diagnostic techniques. These facilities can produce high-speed radiographic images that contribute to our understanding and simulation of weapon physics:

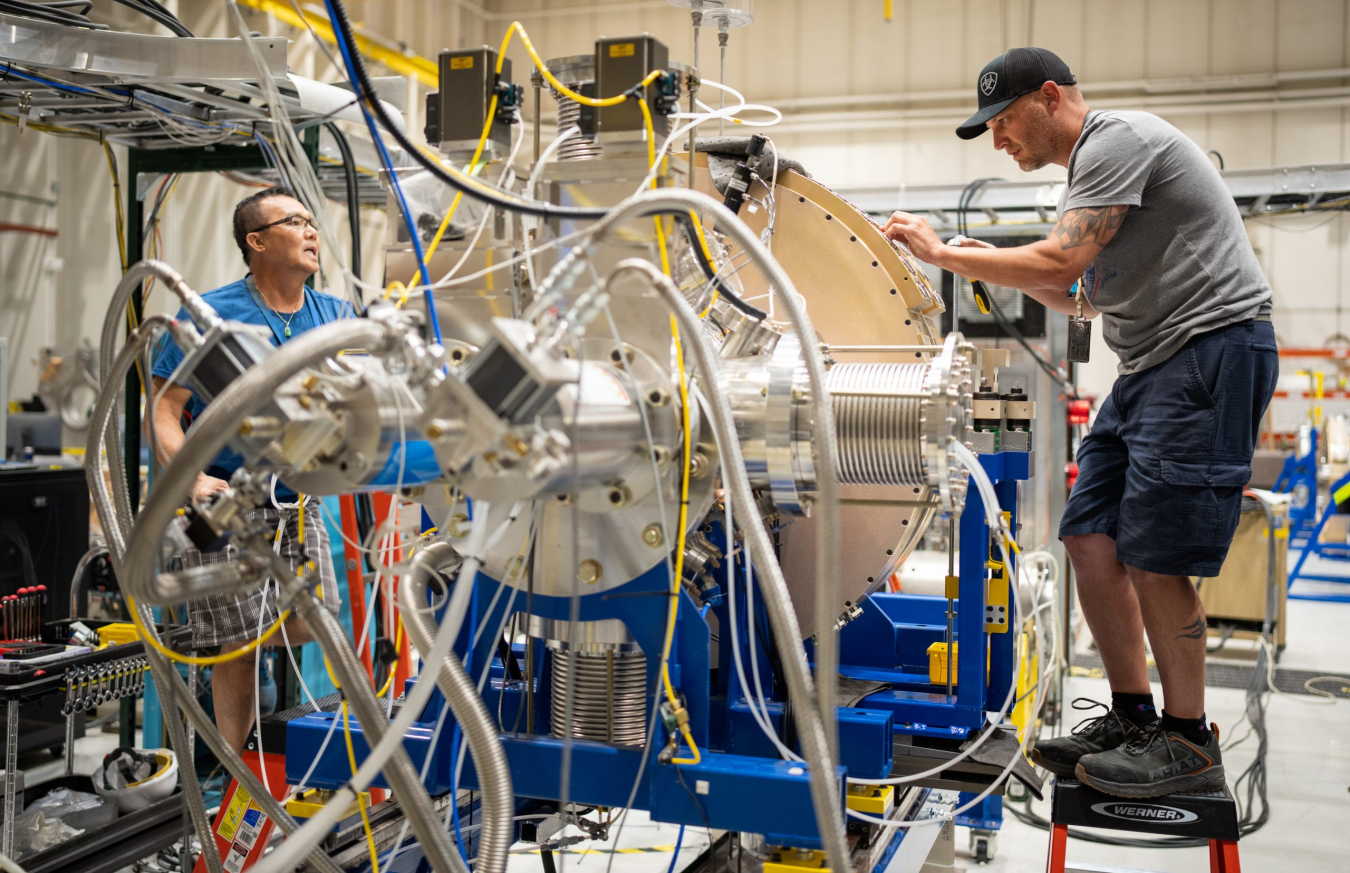

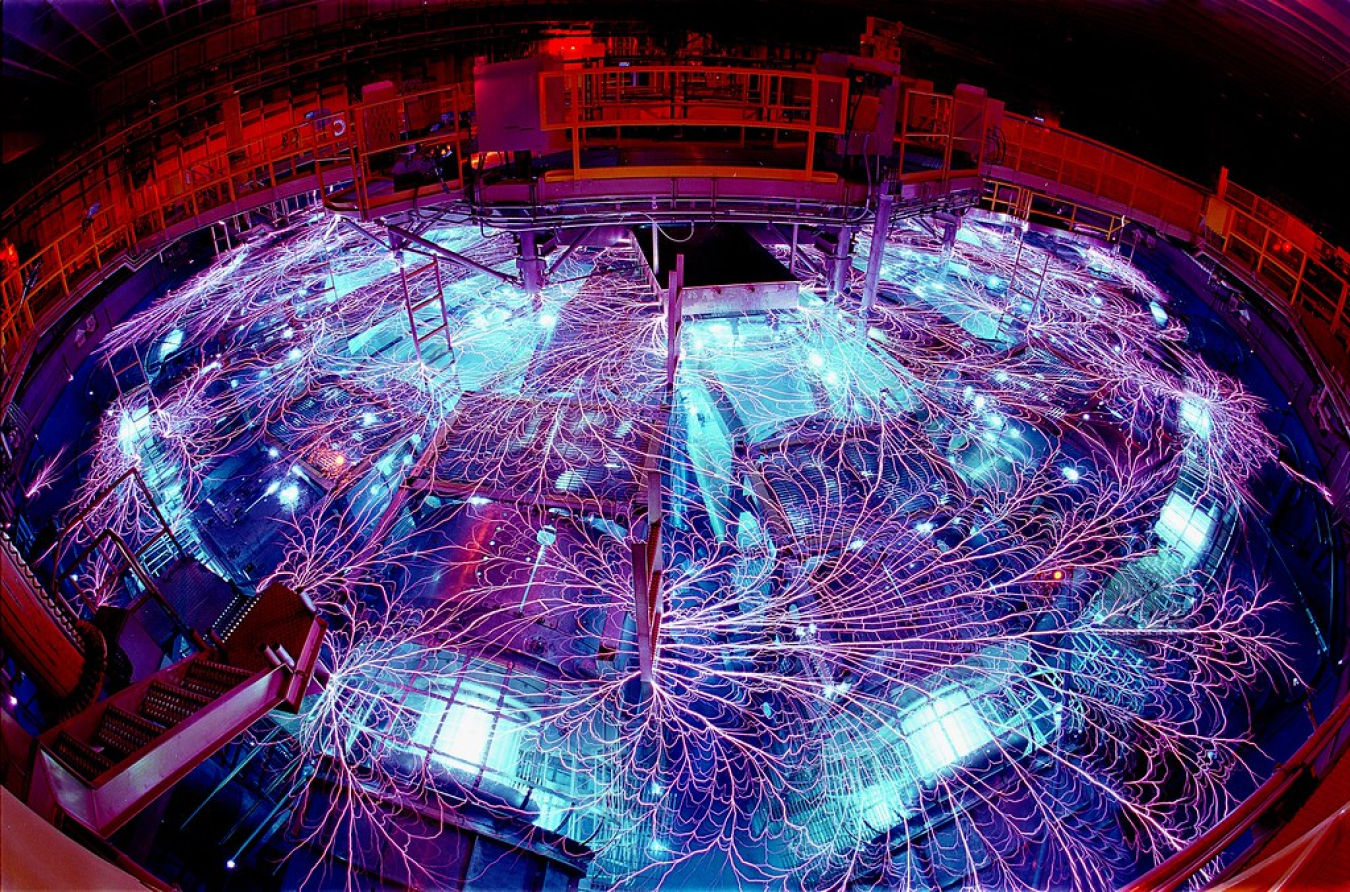

A joint LLNL/Sandia National Labs team commissioned a Line VISAR diagnostic at Z machine, Sandia’s pulsed power facility.

A joint LLNL/Sandia National Labs team commissioned a Line VISAR diagnostic at Z machine, Sandia’s pulsed power facility.Understanding the properties and behavior of matter and radiation at extreme temperature, pressure, or density is necessary to explore fundamental weapons physics issues and validate the codes and models used to certify the stockpile. Scientific knowledge and experimental capabilities in high energy density physics contribute to national capabilities in this area, including:

NNSA's first exascale-class supercomputer, El Capitan, hosted at LLNL.

NNSA's first exascale-class supercomputer, El Capitan, hosted at LLNL.NNSA delivers cutting-edge computer platforms, sophisticated physics and engineering codes, and uniquely qualified technical experts to address a wide range of stockpile issues concerning design, physics certification, engineering qualification, and production. Advanced technology systems serve as tri-laboratory resources, allowing weapon physicists and engineers to tackle the most challenging simulation problems of our age:

Read more about high-performance computing.

The Advanced Simulation and Computing (ASC) program’s high-performance simulation and computing capabilities inform critical Stockpile Stewardship decisions. By continually developing and deploying credible, science-based simulation tools to certify the current and future stockpile, the program assures confidence in the nation’s nuclear deterrent.

In collaboration with the DOE Office of Science, NNSA is accelerating delivery of a capable exascale computing ecosystem for breakthroughs in scientific discovery, energy assurance, economic competitiveness, and national security through the Exascale Computing Project.

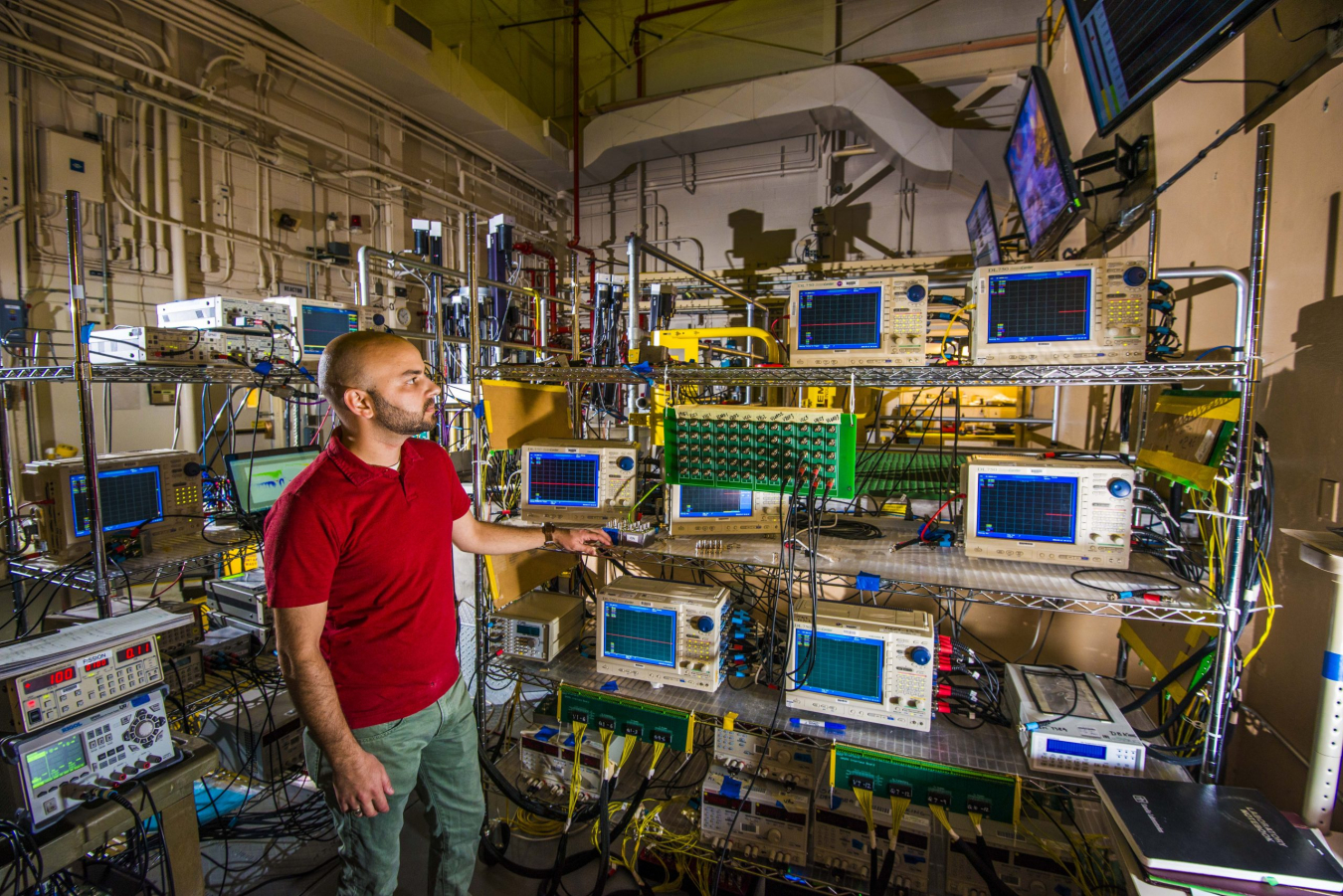

Worker at Sandia National Labs looking over the Qualification Alternative to Sandia Pulsed Reactor (QASPR)

Worker at Sandia National Labs looking over the Qualification Alternative to Sandia Pulsed Reactor (QASPR)The Integrated Assessments programs provide support, coordination, and solutions for the future stockpile at a system level. The team brings together the results of R&D from the Engineering and Weapon Technology and Manufacturing Maturation teams. Technical experts lead preliminary studies, analysis of alternatives, and feasibility assessments to develop the nation’s next weapon systems. NNSA’s labs, plants, and sites pursue responsive technologies through rapid design-build-test cycles, paired with new approaches to qualify components and materials for use in the stockpile. Integrated Assessments conducts ground and flight testing to reduce risk on new candidate technologies and demonstrate system performance in actual flight tests experiencing combined environments.

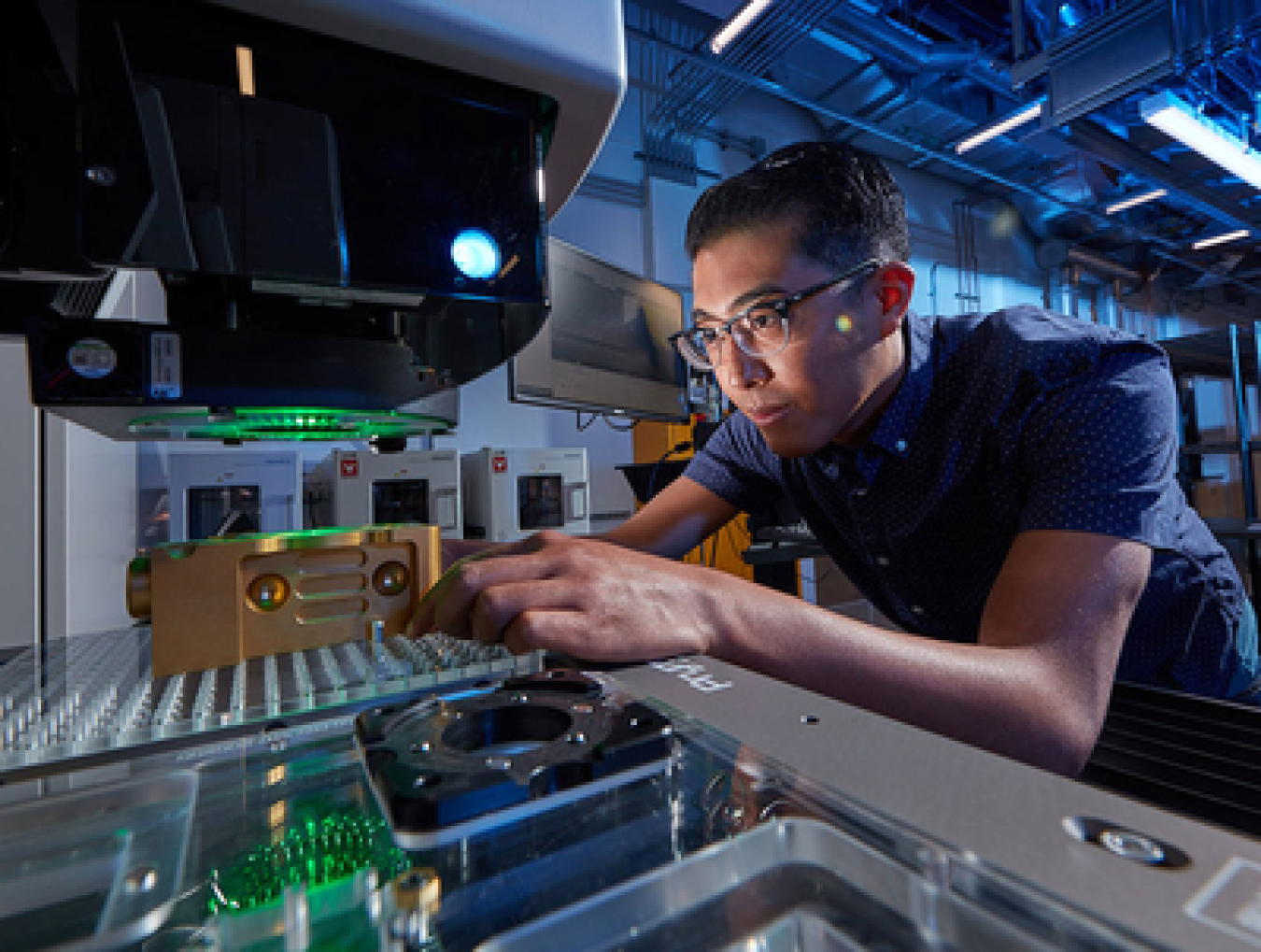

A characterization engineer at LLNL assesses the quality of parts.

A characterization engineer at LLNL assesses the quality of parts.NNSA’s Weapon Technology and Manufacturing Maturation program develops agile, affordable, assured, and novel technologies and capabilities for nuclear stockpile sustainment and modernization. Research and development efforts include new materials and advanced manufacturing techniques, such as additive manufacturing (also known as 3D printing) to improve weapon component production, enable new component design, and replace hazardous materials with safer alternatives. Such efforts enhance resilience by enabling stockpile and production capabilities to transition away from legacy systems, materials, and processes. These advanced materials and processes are at the forefront of technological capabilities and have driven developments in material and process modeling, including integration with artificial intelligence and machine learning. These technologies and maturation make for a more efficient, robust, and responsive weapons complex.

NNSA’s Engineering program develops foundational technologies and enterprise capabilities to ensure a responsive nuclear deterrent. Engineering activities consist of research and development, testing, and evaluation for stockpile qualification, certification, and assessment, with a focus on future challenges facing the U.S. nuclear deterrent. These include future delivery environments, hostile threats, and component and material aging concerns. Program activities ensure survivability in present and future stockpile-to-target sequences. The Engineering program provides tools for qualifying weapon components and certifying weapons without nuclear explosive testing. Capabilities are developed to accelerate the weapons acquisition process and strengthen the nation’s ability to respond to unexpected nuclear threats. The tools, technologies, methods, and data developed within the program ensure the viability and success of ongoing nuclear modernization programs.

Production Modernization and Materials Management

Modern U.S. nuclear weapons are among the most sophisticated devices ever developed, composed of thousands of materials and components that are designed and manufactured to precise specifications. In addition to the fissile cores of the weapons, high explosives are used to generate a nuclear detonation, and a multitude of non-nuclear components enable the reliable functioning of the weapons.

Much of the production base that made these materials and components during the Cold War has since been shuttered. The United States is now recapitalizing its production facilities and infrastructure as part of a broader strategy to modernize the nuclear deterrent. This revitalized enterprise will enable timely adaptation to changing requirements driven by a shifting global security environment, all while avoiding much of the waste, inefficiency, and environmental toll that characterized the first decades of the nuclear age.

Major construction projects are underway across the country to refurbish existing facilities and build new, state-of-the-art production complexes for the nuclear stockpile. In particular, facilities are being built to manufacture the plutonium “pits” at the heart of our nuclear weapons and process uranium, lithium, and tritium for the stockpile. Such investments are critical to answering the challenge of deterring two nuclear peer adversaries in the coming decades and assuring America’s allies and partners over the long term.

These projects require extraordinary choreography to maintain current rates of production while simultaneously building the capacity for the future stockpile. Furthermore, like many U.S. defense systems, nuclear weapons rely on commercially manufactured parts and components, requiring close partnerships between NNSA and private sector companies to provide assurance that the quantity and quality of each meets the nation’s needs.

As the current weapons in our inventory age, NNSA must ensure the nuclear stockpile is properly sized and militarily effective for many decades to come.

Two technicians at LANL using a glove box, a sealed compartment that is accessed through two holes to which gloves are attached.

Two technicians at LANL using a glove box, a sealed compartment that is accessed through two holes to which gloves are attached.The preeminent component in all U.S. nuclear weapons is the plutonium “pit,” a hollow shell of metal about the size of a bowling ball. The explosively driven implosion of the pit releases extraordinary amounts of energy when the weapon detonates. Without plutonium pits there can be no nuclear stockpile.

Pit performance degrades over time, and most pits in our stockpile are more than 30 years old. During the Cold War, the United States manufactured hundreds of pits per year at the Rocky Flats Plant in Colorado, but the plant ceased operations in 1989. Although we possess a large inventory of plutonium, the technical means to fashion this metal into pits has atrophied. Consequently, we are restoring the capability to manufacture pits at quantities needed to fulfill military requirements. Replacing aging pits is a proactive measure to ensure the reliability of the U.S. nuclear deterrent for many decades to come.

NNSA is pursuing a two-site solution to produce new pits—the Los Alamos Plutonium Facility – 4 (PF-4) in New Mexico and the Savannah River Plutonium Processing Facility (SRPPF) in South Carolina. PF-4 is an operating facility that has produced “war-reserve” pits (certified to be fielded in the deployed stockpile) since 2000 and today is manufacturing “development” pits and preparing to manufacture certified pits. SRPPF will occupy a facility that was constructed for a different purpose and is not in use today. Operating two geographically separated facilities provides resilience against disruptions, single-point failures, or other risks that may affect operations at a single site.

Read more about pit production: NNSA Pit Production Efforts Factsheet

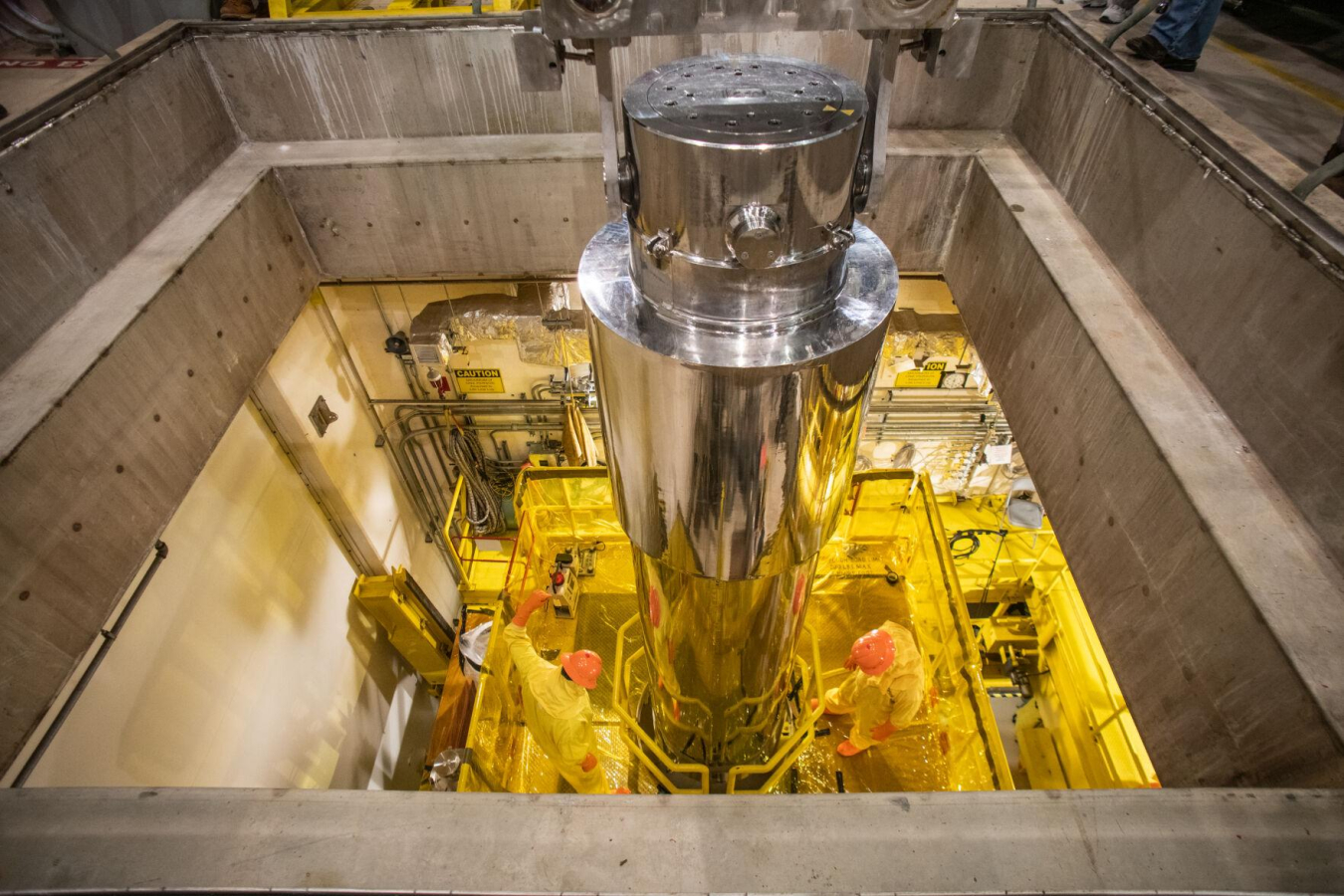

Y-12 National Security Complex chemical operators lower a reactor vessel into a furnace. The homogenization technology was developed by Y-12 scientists and engineers.

Y-12 National Security Complex chemical operators lower a reactor vessel into a furnace. The homogenization technology was developed by Y-12 scientists and engineers.An important material used in the nuclear stockpile is lithium. Since the 1940s, the United States has processed lithium at a site now known as the Y-12 National Security Complex in Tennessee. The current lithium facility dates back to the Manhattan Project and is deteriorating due to its age and the corrosive nature of materials used in lithium operations. Upon completion of the new Lithium Processing Facility (LPF) at Y-12, NNSA will relocate lithium work to this safe, reliable, modern building, which will incorporate more efficient production processes. LPF will also field new technologies that allow for the rapid and efficient recycling of lithium from dismantled weapons. In the meantime, NNSA is restarting lapsed capabilities and investing in the current processes and facility to ensure lithium parts can continue to be produced safely until LPF is completed.

Looking down the Tritium Extraction Facility at Savannah River Site.

Looking down the Tritium Extraction Facility at Savannah River Site.Tritium, an isotope of hydrogen, is required for limited-life components in the nuclear stockpile and must be regularly replenished with new stores. To ensure an adequate tritium production capacity, NNSA is optimizing tritium production, making investments to modernize aging infrastructure and equipment, and performing R&D to improve processes.

Tritium is obtained for the stockpile in two ways—by recovering tritium gas from bottles returned from the stockpile and by producing new tritium in nuclear reactors. We recover and purify tritium from reservoirs returned from the stockpile at the Savannah River Site. We also produce new tritium by irradiating tritium-producing burnable absorber rods (TPBARs) in the Watts Bar Nuclear Plant reactors operated by the Tennessee Valley Authority (TVA).

NNSA fabricates and assembles TPBARs using commercial vendors, irradiates the TPBARs at TVA, transports them to the Savannah River Site where the tritium is extracted at the Tritium Extraction Facility and then purified. We are working to increase the number of TPBARs that can be irradiated on a per-cycle basis, which would provide for higher tritium production and production margin for surge capacity.

NNSA is reestablishing a Domestic Uranium Enrichment (DUE) capability to support two critical defense missions. Low-enriched uranium (LEU) enables the production of tritium, which is used in the nuclear stockpile. Highly enriched uranium (HEU) is used to fuel the nuclear reactors that power the U.S. Navy’s submarines and aircraft carriers.

NNSA currently meets these defense needs using existing stocks of enriched uranium produced during the Cold War. We possess sufficient LEU to fuel tritium production through the early-to-mid 2040s and sufficient HEU for naval propulsion into the 2050s, after which NNSA must reestablish an enriched uranium supply that is unobligated (i.e., free from any peaceful-use restrictions imposed by foreign partners).

NNSA is executing a strategy to provide LEU for tritium production by the early 2040s. This strategy includes: (1) downblending unobligated HEU to LEU to meet near-term demands; (2) advancing and deploying the Domestic Uranium Enrichment Centrifuge Experiment (DUECE) at Oak Ridge National Laboratory; and (3) deploying the AC100 centrifuge technology. Both centrifuge technologies will be considered for full-scale, long-term deployment. NNSA’s DUE program is focused on meeting critical defense requirements on time and establishing an enduring U.S. enrichment capability.

An HEU metal button.

An HEU metal button.The United States has not enriched uranium for nuclear weapons since 1964 and the current highly enriched uranium stockpile is finite and cannot be replaced. To make enriched uranium parts for U.S. nuclear weapons, NNSA recycles material from dismantled weapons.

NNSA is modernizing the facilities and processes needed to recycle enriched uranium. We are also constructing a new facility, the Uranium Processing Facility (UPF) at Y-12. This is the largest NNSA project currently under construction. Once complete, this modern facility will replace many enriched uranium operations currently located in an aging building where operations support a wide range of national security missions. Other enriched uranium operations are being relocated to other facilities that NNSA is updating by modernizing technology and equipment to ensure a safer and more efficient capability and extend their operational life.

In addition to maintaining the nuclear stockpile, uranium experts at Y-12 advance nuclear nonproliferation by enabling material extractions around the world and demonstrating nuclear detection capabilities to thwart the illicit transport of uranium by smugglers and terrorists. The U.S. Navy’s fleet of submarines and aircraft carriers also receives nuclear fuel from Y-12.

Two important materials in nuclear weapons are depleted uranium and an alloy of depleted uranium and niobium called binary. NNSA’s ability to maintain the nuclear stockpile is dependent on a robust supply of high-purity depleted uranium (HPDU), metal alloying capabilities, and reliable component manufacturing capabilities.

NNSA is reestablishing and modernizing lapsed capabilities so we can meet imminent weapons delivery mission requirements. These capabilities lapsed in the early 2000s due to designs that allowed for a reuse of depleted uranium and binary components. NNSA is now working to reestablish a reliable supply of HPDU feedstock material before the current inventory is exhausted and restore the capability to produce new HPDU material. We are also maintaining and restarting various operations to produce binary and the processes used to manufacture and machine components to meet current and future weapon component needs. Finally, we are investing in key new technologies to modernize production to make the process safer and more efficient.

An explosives test detonated at the Minie firing site at LANL.

An explosives test detonated at the Minie firing site at LANL.Nuclear weapons incorporate high explosives and energetics to drive the implosion of the weapons’ fissile cores and other weapon functions. NNSA uses dozens of such materials for the main charges, detonators, boosters, and many additional features of nuclear weapons. Some are produced in-house at NNSA sites, and others are acquired from commercial vendors. NNSA also conducts rigorous research and development, testing, and qualification of high explosives and energetics.

NNSA is ensuring sufficient supplies of these materials as stockpile demands consume the inventory of legacy reserves, the vendor base contracts, and internal infrastructure ages. We continue to modernize and expand the infrastructure to meet unexpected production surge demands and maintain qualified material on the shelf. NNSA is reconstituting legacy manufacturing processes and developing new methods and materials to meet current and future mission needs.

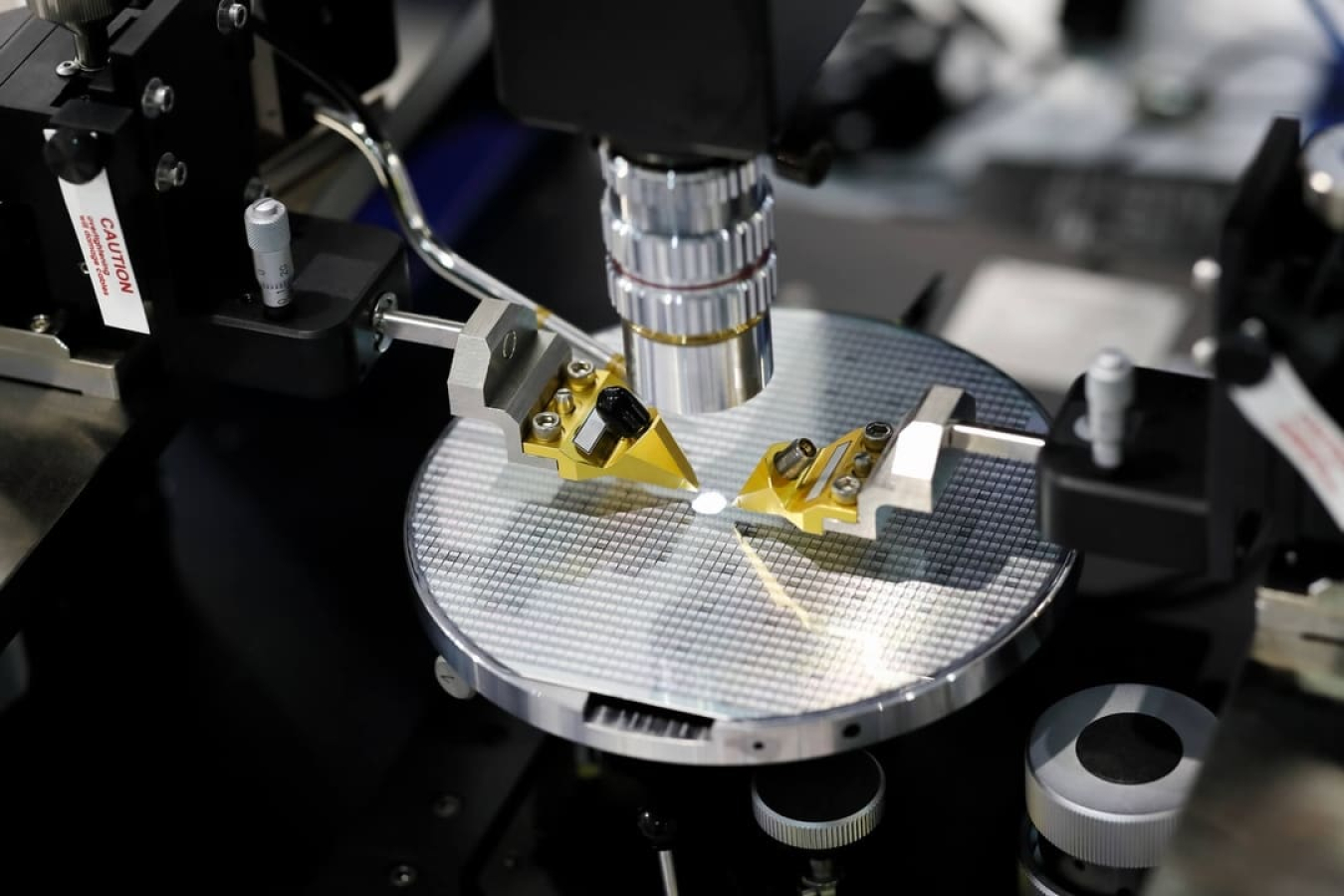

Sandia National Labs showcasing its fabrication, testing, and validation capabilities at its MESAFab complex.

Sandia National Labs showcasing its fabrication, testing, and validation capabilities at its MESAFab complex.In addition to primaries, secondaries, and high explosives, a wide variety of non-nuclear components are necessary for nuclear weapons to function. These include arming, fuzing, and firing mechanisms; key safety and use control features; and other vital elements. NNSA maintains an extensive foundation of capabilities to support the non-nuclear component lifecycle (design, development, qualification, production, and surveillance) to ensure these components meet stockpile requirements.

The two primary sites for non-nuclear components are the Kansas City National Security Campus and Sandia National Laboratories. NNSA is comprehensively addressing challenges at these facilities, including insufficient manufacturing space. The Kansas City Non-Nuclear Component Expansion Transformation (KC NExT) represents NNSA’s long-term plan to provide sufficient capacity plus margin, production flexibility, and mitigate single-point failure risks. At Sandia, the Microsystems Engineering, Science and Application (MESA) complex has facilities and equipment in need of modernization. Consequently, NNSA will execute the MESA Extended Life Program Plan to ensure reliable components through at least 2040. Sandia is also modernizing its power sources capability and combined radiation effects capability (called the Annular Core Research Reactor) via replacement facilities designed for future growth and mission flexibility.

NNSA is also taking measures to ensure a safe, secure, and viable supply chain for non-nuclear components. One such effort is to execute an assured technical basis to integrate commercial electronic parts in defense systems. We also maintain strong, long-term relationships with industry partners to keep pace with technology advancements and trends with implications for non-nuclear components.

Technology and Partnerships

NNSA maintains partnerships with federal and non-federal entities to apply outside technical and commercial knowledge to sustain the nuclear deterrent and advance broader national security missions. To ensure a pipeline of qualified technical talent to the nuclear security enterprise, the Technology and Partnerships Office (TPO) oversees NNSA’s investment in Academic Programs that fund scientific research in areas crucial to nuclear weapon science. We also provide fellowships for exceptional students in key science, technology, engineering, and mathematics fields.

The Stevenson-Wydler Technology Innovation Act of 1980 began the requirement that federal laboratories must budget for and participate in Technology Transfer—the process by which knowledge, facilities, or capabilities developed with federal research and development funds are used to fulfill public and private needs. The TPO works with NNSA’s laboratories, plants, and sites and oversees technology transfer activities to commercialize viable NNSA innovations for the benefit of the nation.

Systems Engineering and Integration

The nuclear deterrence mission is extraordinarily complex, involving numerous military specifications and national policies to deliver a safe, secure, and reliable deterrent. At the intersection of these requirements sits a team of experts who provide the tailored processes, tools, and training for the federal workforce to manage nuclear stockpile programs and projects.

The Office of Systems Engineering and Integration is responsible for enabling informed decision-making across the nuclear security enterprise. This process involves systematically defining and implementing enterprise-level requirements to align stockpile activities with the policy drivers of the deterrence mission. The office serves as the connective tissue between NNSA’s eight national laboratories, plants, and sites in assessing and managing risk to the stockpile mission. Experts lead strategic planning and portfolio analyses concerning the workforce and production capacity, including modeling and simulation of NNSA’s ability to deliver nuclear weapons to the Department of Defense on schedules consistent with national security.

Another key function of the office is engaging with stakeholders inside and outside of the U.S. Government. Experts lead negotiations with DoD counterparts concerning military requirements for U.S. nuclear weapons, engaging with the U.S. Air Force, Navy, Joint Staff, Office of the Secretary of Defense, and combatant commands. The office also works closely with partners in the private sector, performing industrial base monitoring to ensure suppliers of components and materials for the stockpile are commercially viable. As part of this portfolio, we conduct supply chain risk management to confirm that critical supplies are available and free from foreign subversion or manipulation. Together these activities provide assurance that the nuclear security enterprise can deliver a reliable and militarily effective stockpile for as long as our national security depends on it.

How NNSA moves nuclear weapons and materials

NNSA’s Office of Secure Transportation (OST) is responsible for the safe and secure transport of U.S. nuclear weapons, components, and special nuclear materials such as enriched uranium and plutonium in the contiguous United States. This classified cargo is transported in highly secure tractor-trailers and escorted by armed Federal Agents in other vehicles, who provide security and respond in the event of emergencies.

A wide range of activities across the nuclear security enterprise depends on secure transportation—warhead modernization, component exchanges, surveillance, dismantlement, and many others. OST ensures the machinery of the enterprise operates smoothly and securely, allowing NNSA to deliver to the nation the security that our nuclear deterrent uniquely provides.

Since its establishment in 1975, OST has accumulated more than 140 million miles of over-the-road experience transporting special cargo—greater than the distance from the Earth to Mars— with no fatal accidents or releases of radioactive material. OST serves as a model for other nuclear-armed countries, demonstrating the extraordinary care that must be taken to ensure neither accident nor foul play jeopardizes nuclear weapons or materials in transit.

Learn about the qualifications and training to join the ranks of elite Nuclear Materials Couriers: How you can become a part of OST

OST’s Transportation and Emergency Control Center (TECC) is a nationwide communications system located in Albuquerque, New Mexico. The center monitors the status and location of every convoy and maintains real-time communications 24 hours a day, 365 days a year during transportation operations. The TECC has the ability to immediately contact any first responder organization within the United States.

As part of its commitment to safety and security, NNSA makes every effort to ensure its convoys do not travel during inclement weather. Should the convoys encounter adverse weather, provisions exist for the convoys to seek shelter at previously identified secure facilities.

OST’s liaison program provides in-depth mission briefings to federal, Tribal, state, and local law enforcement and public safety agencies nationwide on which OST depends for support, raising awareness of the OST mission. The program provides information to assist first responders during an OST emergency and provides direction for working with Federal Agents during such an event.

Since 1947, NNSA and its predecessor agencies have moved nuclear weapons, components, and special nuclear materials by commercial and government transportation modes. In the late 1960s, worldwide terrorism and acts of violence prompted a review of procedures for safeguarding these materials, resulting in new regulations and equipment to enhance their safety and security in transit.

Subsequently, the Transportation and Safeguards Division (TSD) was established in 1975 at the Department of Energy’s Albuquerque Operations Office. TSD modified and redesigned transport equipment to incorporate features that enhanced self-protection and denied unauthorized access to nuclear weapons and materials. TSD curtailed the use of commercial transportation systems and moved to a completely federal transportation system.

When NNSA was established as a semiautonomous agency within the Department of Energy, the Albuquerque Operations Office and its entire mission fell under the direction of NNSA. The Office of Transportation Safeguards (OTS) replaced TSD.

In 2002, NNSA implemented a new organizational structure to consolidate the Albuquerque Operations Office with other operations offices into what is now the Albuquerque Complex. OTS was renamed the Office of Secure Transportation and reports to NNSA’s Deputy Administrator for Defense Programs in Washington, D.C.

There are three commands from which OST Federal Agents operate:

- Albuquerque, New Mexico

- Amarillo, Texas

- Oak Ridge, Tennessee

OST headquarters is located in Albuquerque, while the OST Training Command is located at Fort Chaffee, Arkansas.

NNSA's Defense Programs news and press releases

-

- Nuclear Security

- Nuclear Stockpile

- National Labs

- Advanced Manufacturing Processes

- American Manufacturing

October 2, 2024 -

- Nuclear Nonproliferation

- Nuclear Security

- Nuclear Stockpile

- National Labs

- International Meetings and Forums

July 15, 2024 -

- Nuclear Security

- Careers

- National Labs

- Naval Nuclear Propulsion

- Nuclear Stockpile

May 20, 2024 -

- Nuclear Nonproliferation

- Nuclear Security

- Nuclear Stockpile

- National Labs

- Environmental and Legacy Management

December 1, 2023 -

- Nuclear Security

- Nuclear Stockpile

- National Labs

- Investing in America

- Nuclear Energy

November 27, 2023 -

- Nuclear Security

- Nuclear Stockpile

- National Labs

- Advanced Manufacturing Processes

- American Manufacturing

May 1, 2023 -

- Nuclear Security

- Nuclear Stockpile

- National Labs

- Energy Security

- Investing in America

April 24, 2023