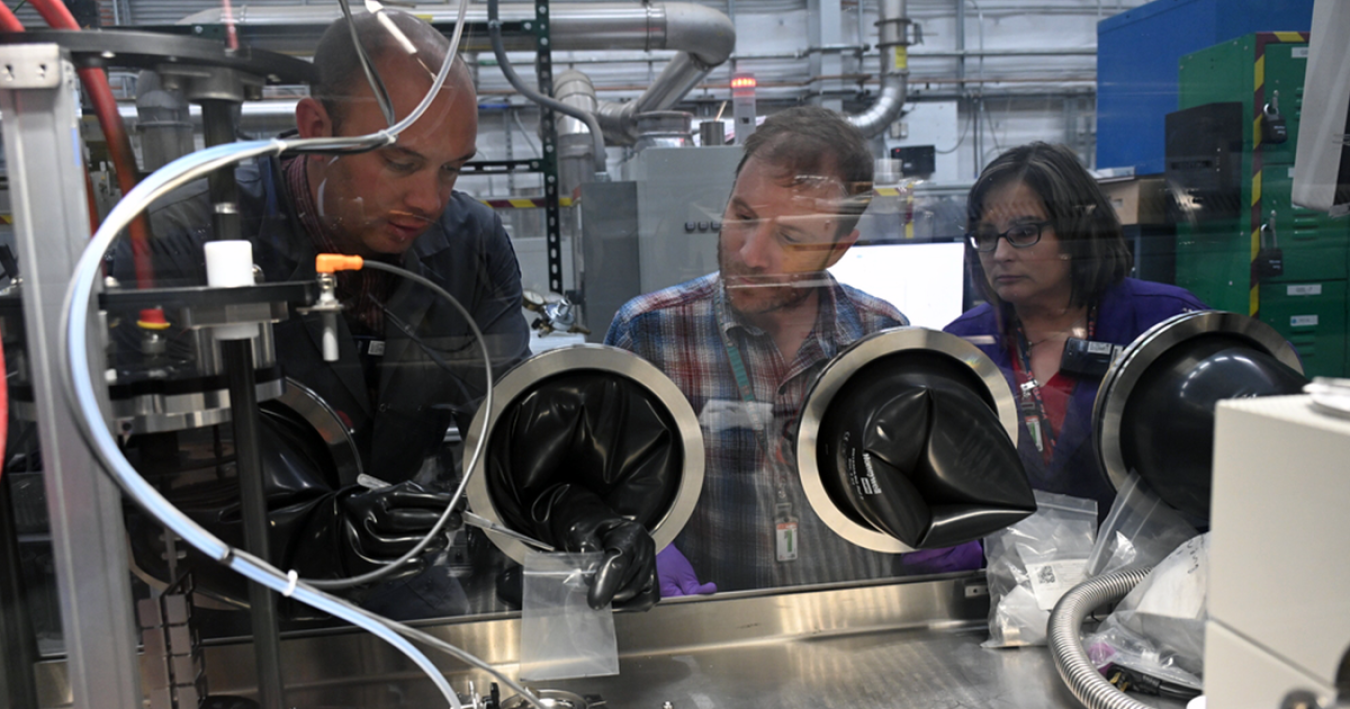

HALEU fuel pellets to be used in testing of GE's advanced cladding concept.

November 21, 2023

Researchers at Idaho National Laboratory (INL) recently made commercial-grade high-assay low-enriched uranium (HALEU) fuel pellets.

The pellets will be used to support the testing of General Electric’s accident tolerant fuel concept and demonstrate the lab’s unique ability to provide customized fuel for industry and government partners.

Manufacturing HALEU Fuel Pellets

Researchers fabricated about two dozen fuel pellets of uranium dioxide HALEU at the lab’s Experimental Fuels Facility.

The pellets were made with a similar sintering technique that is used by industry to make light water reactor fuel.

The high density HALEU pellets are about the size of a gummy bear and contain fuel enriched to 15 percent uranium-235—the main fissile isotope that produces energy during a nuclear reaction. Current reactors typically operate on fuel that is enriched to less than 5 percent.

HALEU is enriched between 5% and 19.75% and is required for most U.S. advanced reactors to achieve smaller designs and allows developers to optimize their systems for longer life cores, increased efficiencies, and better fuel utilization.

The successful demonstration also highlights INL’s unique capabilities to manufacture different types of fuel samples and tailor enrichments to customer and experiment requirements.

“INL is the best place in the U.S. to develop fabrication processes for unique and novel fuel concepts,” said Jennifer Watkins, a nuclear fuels and materials scientist at INL leading the project. “INL has one of the widest ranges of feedstock options at a variety of enrichment levels and an extremely flexible DOE-based enrichment license allowing for adaptability to user needs.”

Testing with General Electric

Researchers plan to finish up testing on the HALEU fuel pellets to evaluate their properties and identify impurities.

They will then fabricate another 100 to 150 pellets to support the testing of General Electric’s specialized cladding material in INL’s Advanced Test Reactor that could improve the performance of existing light water reactors and future advanced reactors.

This project is being funded under the Accident Tolerant Fuel Program in U.S. Department of Energy’s Office of Nuclear Energy.

Westinghouse, General Electric, and Framatome are currently working with the Department to develop and commercialize new cladding and fuel designs that significantly increase plant performance and enhance the safety response to severe accidents in today’s reactors before the end of the decade.