HALEU is enriched between 5% and 20% in U-235 and is required for most U.S. advanced reactors to achieve smaller designs.

December 3, 2024Dozens of U.S. companies are developing advanced reactors that will completely change the way we think about the nuclear industry.

Most of these new reactor designs will be smaller, more flexible, and less expensive to build. Some of these reactors may help bring reliable power to communities never thought possible and other designs could consume used nuclear fuel.

The majority of these designs will require a fuel that isn’t yet available at a commercial scale.

It’s what the industry calls high-assay low-enriched uranium, or HALEU for short, and these companies can’t bring their reactors to life without it.

What is High-Assay Low-Enriched Uranium?

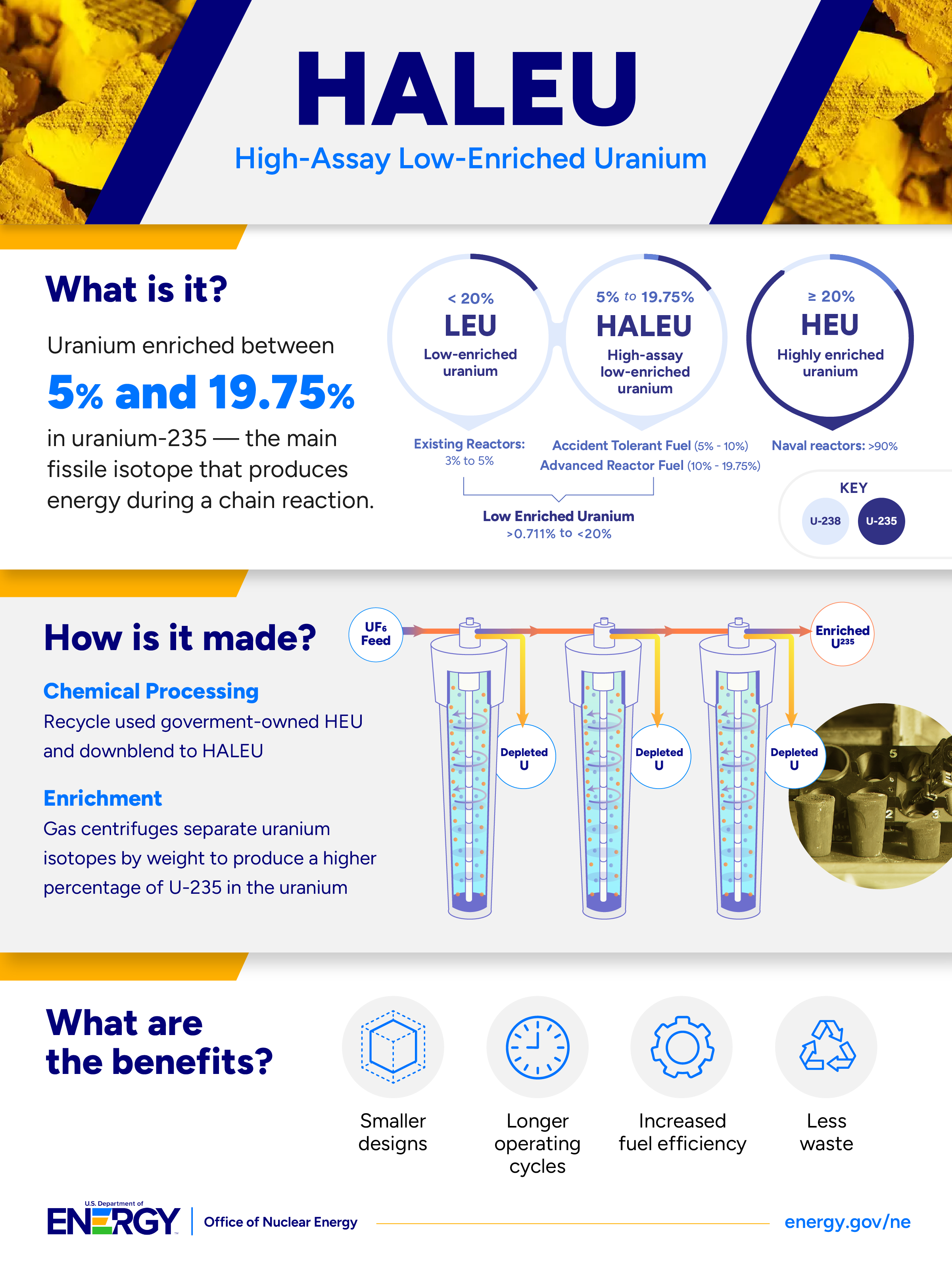

Our existing fleet of reactors runs on uranium fuel that is enriched up to 5% with uranium-235 — the main fissile isotope that produces energy during a chain reaction.

By definition, HALEU is enriched between 5% and less than 20% and is required for most U.S. advanced reactors to achieve smaller designs that get more power per unit of volume. HALEU will also allow developers to optimize their systems for longer operating cycles, increased efficiencies, and better fuel utilization.

The Growing Need for HALEU

There’s a pressing need for HALEU now — without it, the development, demonstration, and deployment of many advanced nuclear technologies may be in jeopardy.

The U.S. Department of Energy (DOE) estimates the domestic demand for HALEU could reach 50 metric tons per year by 2035, with additional amounts required each year.

To help mitigate that risk, DOE is exploring three options to provide HALEU to advanced reactor developers to support the testing and demonstration of these advanced reactors.

Recovery and Downblending of Existing DOE Material

DOE and its national labs are working on two chemical processes to provide small amounts of HALEU to vendors in the near future. Both methods involve the recycling of used nuclear fuel from government-owned research reactors to recover highly enriched uranium (greater than 20%) that can then be down-blended to make HALEU fuel.

Electrochemical Processing

Irradiated fuel from DOE-research reactors is prepared and placed into a high-temperature molten salt chemical bath. An electric current is then used to separate the highly enriched uranium metal from the fission products. The recovered uranium is cleaned and mixed with lower enriched uranium to create HALEU. The uranium is then fabricated into new fuel in a high-temperature furnace.

Idaho National Laboratory is working to make up to 10 metric tons of HALEU available using this process to support current testing and demonstration projects.

Hybrid Zirconium Extraction Process (ZIRCEX)

Irradiated fuels are dissolved in hydrochloric acid gas to remove the aluminum or zirconium cladding. The uranium is then down-blended to between 5% and 19.75% U-235 with lower enriched uranium. The fuel is then passed through a modular solvent extraction system to separate the uranium from its fission products.

DOE is continuing to develop the hybrid zirconium extraction process and is working to demonstrate and develop a lower temperature alternative using Idaho National Laboratory’s Material Recovery Pilot Plant.

Piketon Demonstration Project

DOE partnered with Centrus to manufacture, install, and operate 16 advanced centrifuges at an enrichment facility in Piketon, Ohio.

The company’s AC-100M machine was developed through the years with support from DOE and is being used to demonstrate the enrichment of uranium hexafluoride gas to produce HALEU.

The demonstration project has enriched more than 100 kgs of HALEU and is expected to ramp up production to 900 kgs in the coming years to support near-term HALEU needs for fuel qualification testing and DOE-supported advanced reactor demonstration projects.

Establishing a Domestic HALEU Supply Chain

DOE is working to spur the buildout of a domestic nuclear fuel supply chain for advanced reactors through its HALEU Availability Program.

The Department awarded its first contracts in 2024 that will allow companies to bid on work for enrichment and deconversion services–two key pieces of the HALEU supply chain.

Advancing the domestic HALEU supply chain will help reinforce America’s leadership in the nuclear energy sector and allow nuclear facilities to power even more homes and businesses with affordable and reliable carbon-free energy.

Learn more about the Office of Nuclear Energy’s efforts to ensure access to HALEU for civilian domestic research, development, demonstration, and commercial use through the HALEU Availability Program.

EDITOR'S NOTE: This blog was originally published in April 2020 and is updated regularly.