Last year brought many advances in wind energy. Here are the most influential wind energy stories from 2022 from the Wind Energy Technologies Office.

Wind Energy Technologies Office

January 23, 2023Last year brought many advances in wind energy. From improved turbine manufacturing and recycling methods, to pathways that bring more clean energy to the grid—both through interconnection and by exploring the potential of offshore wind—there's a lot to celebrate.

Here are the most influential wind energy stories from 2022 from the U.S. Department of Energy’s (DOE) Wind Energy Technologies Office (WETO). It’s been a whirlwind of a year.

Floating Offshore Wind Shot™

The Floating Offshore Wind Shot™ will help usher in a clean energy future by driving U.S. leadership in floating offshore wind energy technology design, development, and manufacturing.

The Floating Offshore Wind Shot seeks to reduce the cost of floating offshore wind energy by at least 70% to $45 per megawatt-hour by 2035 for sites in deep water, far from shore.

Goals of the Floating Offshore Wind Energy Earthshot

Animation by the National Renewable Energy Laboratory

Carbon Rivers has achieved 99.9% recycled glass fiber purity from different end-of-life waste streams like wind turbine blades.

Energy technology company Carbon Rivers commercialized a new process to recover 99.9% pure glass fiber from decommissioned fiberglass wind turbine blades, enabling its use in new composite products. This achievement, which resulted from a collaboration with the University of Tennessee, Knoxville, and WETO, could have a global impact on the sustainability of wind energy because materials that previously ended up in post-consumer waste streams can go directly into next-generation turbine blade manufacturing.

Spiral Welding Is Revolutionizing Wind Turbine Tower Manufacturing

Taller land-based wind turbines harness and generate more power than shorter ones because they can access faster wind speeds at greater heights. They’re also difficult and costly to transport from the manufacturing plant to the wind farm, but with support from WETO, Colorado- and Texas-based Keystone Tower Systems is changing how wind turbines can be manufactured, transported, and installed using a spiral-welding technique to build some of the tallest turbine towers on the market.

New Initiative To Improve Clean Energy Interconnection

There are now more than 1,300 gigawatts of wind energy, solar power, and battery capacity seeking grid interconnection, but these projects face long wait times and, in many cases, high costs to upgrade and connect to the grid system.

DOE has partnered with research teams from the Pacific Northwest National Laboratory, Lawrence Berkeley National Laboratory, and the National Renewable Energy Laboratory (NREL) to launch a new initiative—the Interconnection Innovation e-Xchange, which is designed to help clean energy resources connect to the grid. This will enhance overall grid reliability and improve market competition, transmission, and distribution access.

The Interconnection Innovation e-Xchange is designed to help clean energy resources connect to the grid, which will enhance overall grid reliability and improve market competition and transmission and distribution access.

Prize To Accelerate Domestic Supply Chains for Floating Offshore Wind Energy

The FLoating Offshore Wind ReadINess Prize is part of DOE’s American-Made Challenges series.

This three-phase, $6.85 million investment is designed to pave the way for cost-effective domestic manufacturing and deployment of commercial-scale floating offshore wind energy technologies in U.S. waters.

Market Reports Highlight Wind’s Sky-High Growth

U.S. wind energy continued to grow, providing low-cost clean energy to millions of Americans. Three market reports released by WETO in 2022 detail trends in wind energy development, technology, cost, and performance through the end of 2021 (and through May 2022 for offshore wind energy).

Land-Based Wind Market Report: 2022 Edition

The 2022 edition of the Land-Based Wind Market Report provides an overview of developments and trends in the U.S. wind power market for the 2021 calendar year.

Offshore Wind Market Report: 2022 Edition

The 2022 edition of the Offshore Wind Market Report provides offshore wind energy policymakers, regulators, developers, researchers, engineers, financiers, supply chain participants, and other stakeholders with up-to-date quantitative information about the offshore wind energy market, technology, and cost trends in the United States and worldwide.

Distributed Wind Market Report: 2022 Edition

The 2022 edition of the Distributed Wind Market Report provides stakeholders with statistics and analysis of the distributed wind energy market— which includes power from wind turbines installed near where the power will be used—along with insight into its trends and characteristics. The report analyzes distributed wind energy projects of all sizes and details the U.S. small wind market for the 2021 calendar year.

30 teams participated in Phase 1 of the 2023 U.S. Department of Energy Collegiate Wind Competition, which took take place during the first half of the 2022-2023 school year.

Kansas State University rose above 11 other competing teams to claim first place in the 2022 Collegiate Wind Competition. And 30 colleges and universities were selected to participate in Phase 1 of the 2023 competition.

DOE’s Collegiate Wind Competition, which first launched in 2014, helps prepare the future wind energy workforce by inviting college students from a range of disciplines to represent their schools as they design, build, and test a prototype wind turbine; develop a site plan and cost-of-energy analysis for a hypothetical wind farm; and conduct outreach with the wind energy industry, their communities, and local media outlets.

Study Charts Path Toward Significant Growth in Offshore Wind Workforce

NREL report estimated that the offshore wind energy industry will need an average of between 15,000 and 58,000 full-time workers every year from 2024 to 2030, depending on the amount of American-made content used. This is an increase from less than 1,000 workers today.

A strong offshore wind energy workforce will help decarbonize the U.S. power sector and is critical to reaching the Biden administration’s goals of installing 30 gigawatts of offshore wind energy capacity by 2030 and 15 gigawatts of floating offshore wind energy by 2035.

New NREL research illustrates that distributed wind energy systems, such as this one, could be increasingly valuable as rural residents, businesses, and communities drive their own transition to a clean energy future.

A comprehensive analysis released by NREL indicates that nearly 1,400 gigawatts of distributed wind energy capacity could be profitably deployed today across the United States.

This amounts to more than half of the nation’s current annual electricity consumption and is a big increase from the 1.1 gigawatts of wind energy installed in distributed applications through the end of 2021.

Distributed wind energy has the potential to transform the energy portfolio of communities like St. Mary’s, Alaska, where a standalone wind turbine provides significant economic and climate benefits.

Tool Aims To Predict Interactions Between Soaring Eagles and Wind Turbines

While wind energy has many environmental benefits and its expansion is critical to achieving the nation’s clean energy and climate goals, it must be developed in a way that prioritizes coexistence with wildlife. Eagles are particularly important in this context because of their conservation status and protection under law in the United States.

Helping wind farm developers and operators visualize how these magnificent creatures might fly around wind power plants is key to help wind turbines and eagles share space in a safer way. Now, we are one step closer to doing just that.

A new simulator, developed by the National Renewable Energy Laboratory, allows users to model the movements of soaring raptors, such as golden eagles, which prefer to ride updrafts at the same altitudes as wind turbine blades. The model’s predictions at specific locations in the United States, times of year, and wind conditions could help reduce potential collision risks of wildlife with wind turbines.

Study Explores 3D Printing of Permanent Magnets for Wind Turbines

Oak Ridge National Laboratory published a study as part of the MADE3D initiative highlighting 3D printing of permanent magnets for wind turbine generators and other large electrical machines.

Additive manufacturing could be an attractive method for manufacturing permanent magnets, as it minimizes the use and waste of critical, supply-limited rare earth materials and enables printing of complex shapes. It also examines the use of additive manufacturing for permanent magnets on wind turbine generators and how this manufacturing method can address the problems associated with supply chain issues of critical rare earth materials.

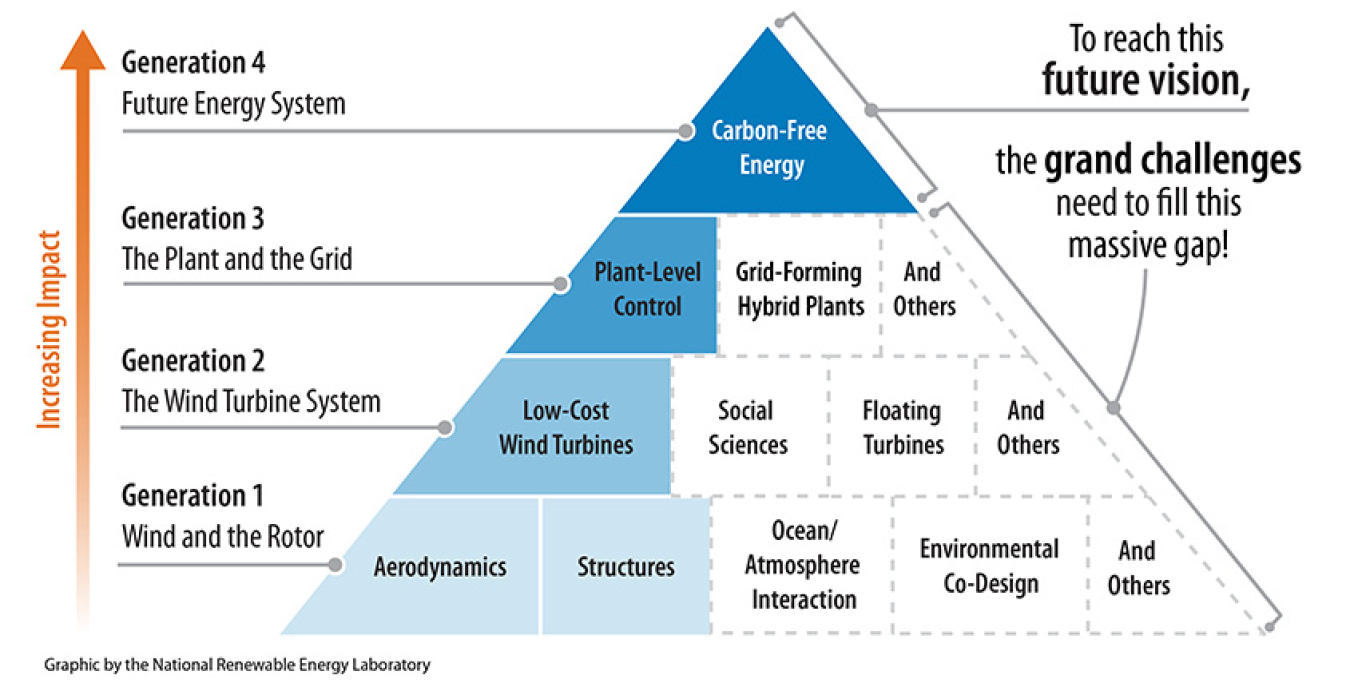

Worldwide Experts Lay Out Grand Challenges of Wind Energy Advancement

To accelerate the global potential of wind energy, the wind energy industry must measure up to critical scientific, social, and environmental challenges. In a series of 10 articles, over 100 wind energy experts from around the world are joining forces to identify the most critical needs for wind energy advancement.

This pyramid illustrates four generations of wind energy development. Each generation's achievements expanded wind energy's impact (shown in the blue boxes on the left); however, in moving quickly from generation to generation, some underlying science was left unresolved (shown in the white boxes on the right). Generation 1 delivered working energy conversion systems, Generation 2 solved low-cost and reliable turbines, and Generation 3 is beginning to provide controllable wind plants that support the grid. The aspirational goal of Generation 4 is a carbon-neutral future energy system. Wind can be the foundation for the fourth generation—but not until the gaps in the previous generations are addressed.

Subscribe to the Catch the Wind newsletter to get the latest news in the new year and learn about opportunities to get involved in wind energy.