Lead Performer: Oak Ridge National Laboratory - Oak Ridge, TN

July 23, 2014Lead Performer: Oak Ridge National Laboratory - Oak Ridge, TN

Partners:

-- Hill Phoenix - Conyers, GA

-- Danfoss - Baltimore, MD

-- Luvata - Kimberly, WI

-- SWEP - Duluth, GA

DOE Funding: $2,455,000

Project Term: October 2011 - September 2016

Project Objective

The objective of this project is to develop a supermarket refrigeration system that reduces greenhouse gas emissions and has 25% to 30% lower energy consumption than existing supermarket refrigeration systems. Performance of the prototype high-efficiency, low-emission refrigeration system will be tested in an environmental chamber to applicable test standards. A laboratory test report will be produced that describes the performance of the prototype refrigeration system operating under the laboratory test conditions. In addition, ORNL will coordinate field testing of a full-scale, high-efficiency, low-emission refrigeration system in a third-party installation. ORNL will also produce a field test report that describes the performance of the full-scale refrigeration system operating under actual field conditions.

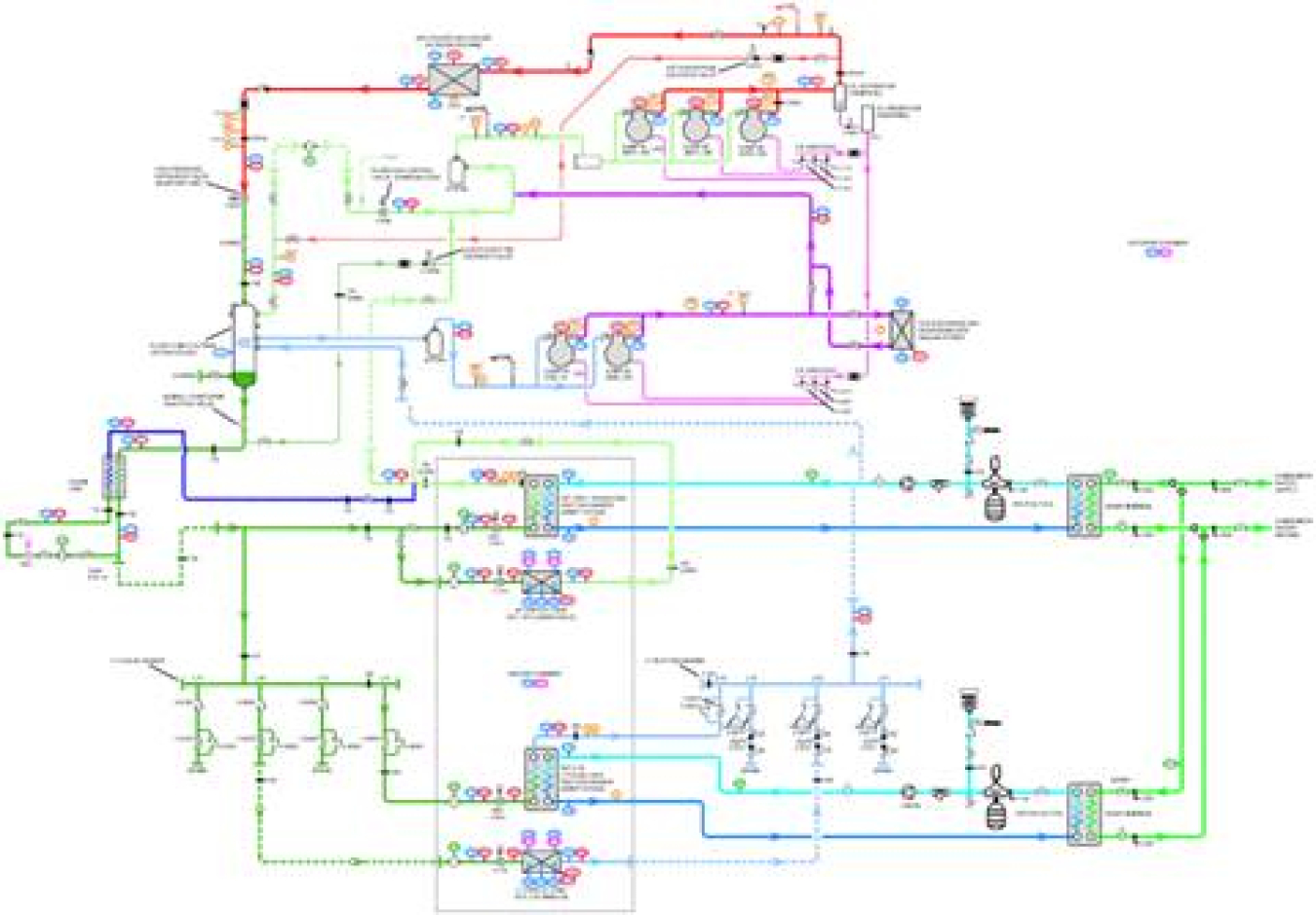

The compressor rack and system diagram for the CO2 refrigeration system. Credit: Oak Ridge National Lab.

Diagram of the compressor rack and system diagram for the CO2 refrigeration system. Credit: Oak Ridge National Lab.

Project Impact

The primary market segment targeted by this project is large national food retailers, followed by the secondary market segment consisting of small food retailers. The results of this project will initially be used to encourage the early adoption of high-efficiency, low-emission refrigeration system technology by major national food retailers. Using their volume buying power, these large food retailers will be able to reduce the cost of the new refrigeration system, thereby increasing the market penetration of the new technology to smaller food retailers. Adoption of advanced refrigeration equipment is required to achieve the Building Technologies Office goal of reducing the energy and carbon emissions of service equipment by 50% compared to today’s best common practice. It is estimated that the primary energy consumption of supermarket refrigeration systems is 688 TWh per year (Navigant 2009). Based on a 25% energy savings from the high-efficiency, low-emission refrigeration system developed in this project and a 10% adoption rate, ORNL estimates annual primary energy savings of 17 TWh.

Contacts

DOE Technology Manager: Tony Bouza

Performer: Brian Fricke, Oak Ridge National Laboratory