Lead Performer: North Dakota State University – Fargo, ND; Partners: Montana State University – Bozeman, MT, Oak Ridge National Laboratory – Oak Ridge, TN, Idaho National Laboratory – Idaho Falls, ID

February 15, 2022

Lead Performer: North Dakota State University – Fargo, ND

Partners:

-- Montana State University – Bozeman, MT

-- Oak Ridge National Laboratory – Oak Ridge, TN

-- Idaho National Laboratory – Idaho Falls, ID

Total Funding: $2,209,783

FY20 DOE Funding: $1,741,747

Cost Share: $468,036

Project Term: October 1, 2021 – December 31, 2024

Funding Type: 2020 BENEFIT Funding Opportunity Announcement

Project Objective

Each year, quadrillions of Btu of energy are consumed in U.S. buildings for thermal end-uses. To meet this demand with renewable or intermittent energy sources, effective thermal energy storage is critical. The primary objective of this project is to develop a new thermochemical energy storage material consisting of a framework of cellulose nanocrystals (CNC) impregnated with hygroscopic salt.

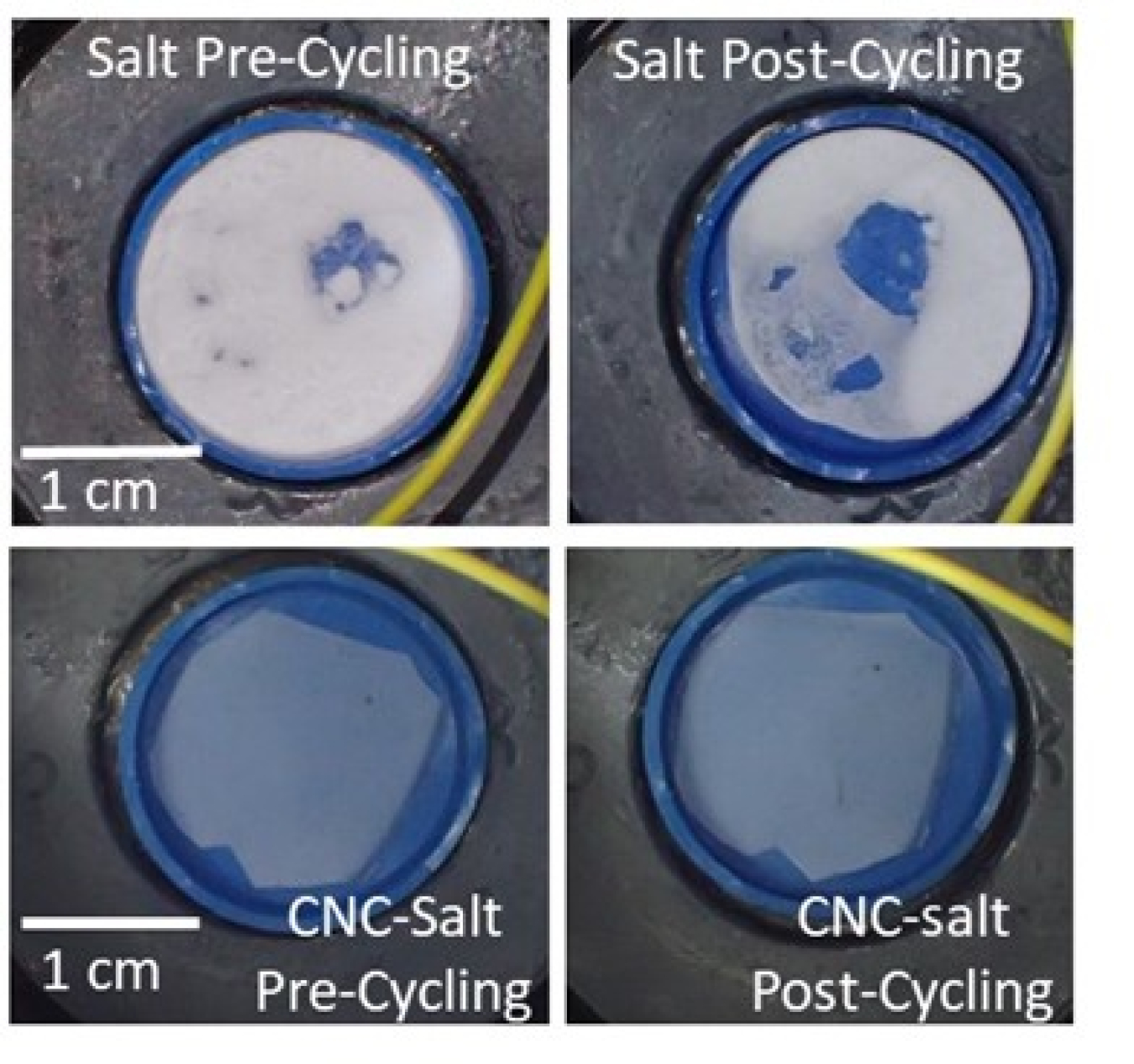

Thermochemical energy storage stores the thermal energy in chemical bonds between molecules. The storage material is charged by heating the material, which drives the endothermic chemical reaction. The reactants are stored separately until discharging. During discharge, the reaction is reversed, exothermically recombining the molecules and thereby releasing the stored energy. Thermochemical energy storage has the potential for high energy density with minimal losses through self-discharging. One reaction that has garnered interest in storage heat for buildings is the hydration and dehydration of salts due to the high theoretical energy density, 100 – 780 kWh/m3, and because the reaction occurs at temperatures appropriate for heating of buildings. However, pure salts are not stable during cycling, which results in a decrease in performance. Improving stability by adding salt to porous host materials, such as expanded graphite and zeolites, has been investigated. However, generally, these host materials work on macro-scale and result in decreasing energy density.

The project will address these issues by developing a composite material consisting of a nanoscale framework of CNC to stabilize the salt. This nanoscale structure will allow for stable, submicron-scale salt particles to be used. This will allow for increased surface area for the reaction and the potential for improved reaction rates and better utilization of the salt. Additionally, the CNC is hydrophilic and thus can participate in the hydration reaction. The project will work to develop this new composite material, determine the methodology to manufacture it, and model its improvement to energy usage in buildings with the following objectives:

- Material energy density ≥ 470 J/g

- Thermal reliability ≥ 90% after 5,000 cycles

- Predicted heating energy savings in buildings ≥ 40%

- Predicted large-scale material cost of < $15/kWhthermal

- Demonstration of performance in lab-scale reactor

Project Impact

Thermal end uses in buildings account for over half of the energy consumed in residential and commercial buildings. Traditionally, this demand has been met by sources such as natural gas, oil, and electric heaters. As such, developing effective, compact thermal energy storage will have significant economic and environmental impact. It can have significant economic value by enabling the use of lower quality energy sources, e.g. waste heat, to meet the load and by time-shifting the load, e.g. charging the system during off-peak hours to provide energy during peak times. It can have environmental impact, e.g. lower CO2 emission, by enabling renewable sources to meet these loads.

However, one of the challenges for the advancement of thermochemical energy storage has been the development a stable material that retains high energy density. Through the approach of utilizing a hydroscopic, nanoscale, stabilizing framework while considering the cost of production early in the material development process, the project will develop such a material. Successful outcome of the project will result in a material that meets the requirements for use in buildings and, through modeling, quantify the effect that the material will have on the energy usage in buildings. Thus, the project will enable more effective energy usage in U.S. buildings.

Contacts

DOE Technology Manager: Sven Mumme

Lead Performer: Adam Gladen, North Dakota State University