For the biomass industry, the Feedstock-Conversion Interface Consortium (FCIC) is researching material handling to enable continuous, steady, trouble-free, bulk flow transport to the reactor throat.

Approach

FCIC’s research approach involves conducting well-controlled particle and bulk flow experiments using industry-relevant biomass. For comprehensive sensitivity studies of engineering-scale flow performance, the research uses experimentally validated models:

- Discrete element

- Finite element

- Computational fluid dynamics.

Outcomes

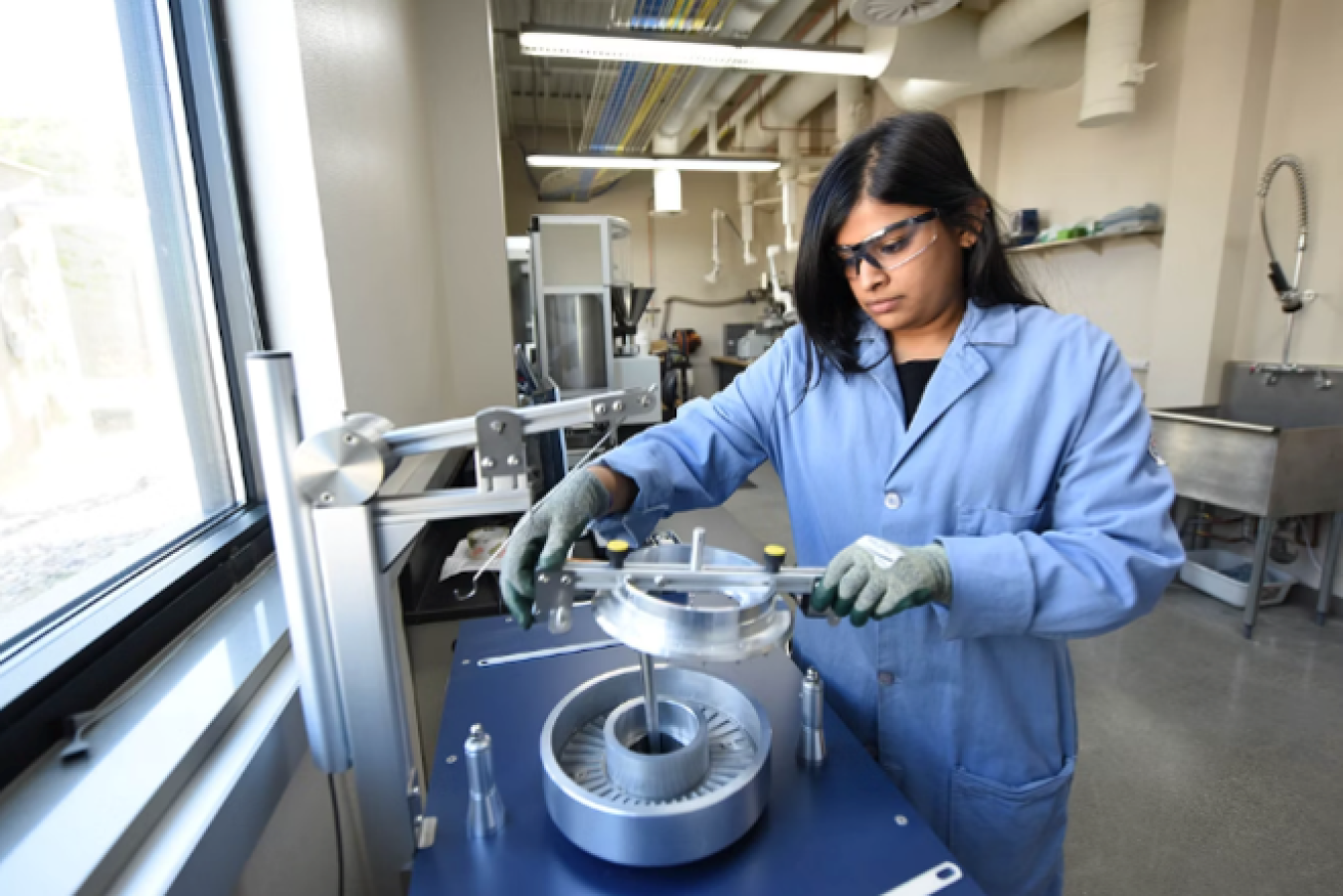

A researcher works on a ring shear tester in the lab. Photo from Idaho National Laboratory.

The FCIC is developing reliable feeding and handling solutions achieved through physics-based, experiment-informed, and validated modeling tools and measurement, and providing open-source feedstock flow simulation tools.

Free Open-Source Tool To Predict Biomass Flow Behavior

Predicting the flow behavior of complex biomass materials continues to be a significant challenge, as their physical and mechanical properties are very different than familiar agricultural commodities like corn and wheat grains. FCIC researchers are developing first-principles-based computational modeling tools to help process engineers understand and predict flow behavior and have made three separate code bases freely available to external stakeholders.

These experimentally validated computational models, which will enable sophisticated modelers in industry and academia to simulate the flow behavior of biomass feedstocks with properties very different from traditional agricultural commodities, are available at the following GitHub repositories:

- Granular Flow Models: User-defined material behavior description subroutines for the computational fluid dynamics modeling package, Abaqus.

- densegranFoam: OpenFOAM computational fluid dynamics model for dense granular material flow.

- LIGGGHTS-INL: An extended version of the LIGGGHTS open-source discrete element method particle simulation software.

Impact

The development of physics-based modeling tools and supporting measurements enables the design and operation of processing train equipment that does not rely on empiricism.

Contact

For more information, contact the FCIC.

Other FCIC Research and Capabilities

Learn about all of FCIC’s research areas and capabilities/facilities.