Explains the importance of hydrogen, its many uses, and what DOE's Hydrogen and Fuel Cell Technologies Office is doing with H2@Scale to innovate.

Office of Energy Efficiency & Renewable Energy

October 8, 2020The U.S. Department of Energy’s (DOE’s) Hydrogen and Fuel Cell Technologies Office, within the Office of Energy Efficiency and Renewable Energy (EERE), launched the H2@Scale initiative in 2016 to explore the potential for hydrogen to enable affordable, reliable, clean, and secure energy across sectors. The initiative brings together National Laboratories and industry experts to accelerate research, development, and demonstration of hydrogen production, delivery, storage, infrastructure, and end-use applications. More recently, H2@Scale has been working to identify new and emerging markets where hydrogen technologies can add value to economic, environmental, and energy resilience fronts.

The key to H2@Scale is that it can integrate different sectors and uses that can benefit from hydrogen, help scale up the volume of hydrogen used, and reduce costs for the end user. Some examples include steel manufacturing, data centers, ports, and medium- and heavy-duty trucks.

Here are five facts you may not know about the H2@Scale vision and projects:

1. Hydrogen can be produced at a large scale from diverse domestic resources.

Hydrogen is the simplest and most abundant element in the universe. It is found within water, fossil fuels, and all living matter, but it rarely exists as a gas on Earth—it must be separated from other elements. There are various domestic resources that can be used to produce hydrogen, including renewables (wind, solar, hydropower, biomass, and geothermal energy), nuclear power, and fossil fuels (such as natural gas and coal – with carbon capture and sequestration). The U.S. currently produces more than 10 million metric tons of hydrogen per year, about one-seventh of the global supply.[1] Recent analysis reports from DOE’s National Laboratories explore the availability of resources within the U.S. to provide hydrogen under different demand scenarios. Resource Assessment for Hydrogen Production examines the resources required to meet demand for an additional 10 million metric tons of hydrogen in 2040.

2. Hydrogen has the highest energy content (by weight) of all known fuels, and is an essential feedstock in multiple industries.

Hydrogen has about 3 times more energy content by weight than conventional fuels like gasoline and natural gas, which is why it was first selected by NASA for space applications. It also has about 4 times less energy density by volume, so it is challenging to store in a limited space. Hydrogen is an industrial commodity today, mostly used for oil refining and fertilizer production. H2@Scale is also looking at hydrogen in industrial manufacturing. For example, take steelmaking. Nearly 6% of delivered energy in the U.S. is used to produce steel, primarily using a carbon product called coke fuel. New production processes are exploring the use of hydrogen gas instead of coke. Hydrogen reacts with iron oxide in a similar fashion to the carbon monoxide derived from coke fuel, but the only byproduct of this reaction is water. This is just one of many emerging hydrogen applications being demonstrated through industry-led projects supported by EERE. H2@Scale also supports more than 25 cooperative research and development agreement projects at National Laboratories and in collaboration with industry that focus on reducing barriers to emerging hydrogen applications, including heavy-duty trucks and blending hydrogen in natural gas pipelines.

3. Hydrogen and fuel cells can enable zero or near-zero emissions in transportation, stationary or remote power, and portable power applications.

When hydrogen is produced from renewable or zero-carbon sources, it becomes a zero-emission energy source. Today in the U.S., hydrogen powers more than 500 MW of stationary fuel cells, 35,000 forklifts, 60 fuel cell buses, and 8,800 fuel cell cars.[2] The H2@Scale initiative is researching the vast impact hydrogen can have on different applications, including heavy duty applications that are hard to decarbonize using other approaches. Examples include heavy duty trucks, rail transportation and maritime applications as well as backup power for data centers. One of DOE’s new National Lab consortia will accelerate development of fuel cells for heavy-duty trucks – an application receiving interest worldwide.

4. Hydrogen can be used as a “responsive load” to enable grid stability and seasonal, long-duration energy storage.

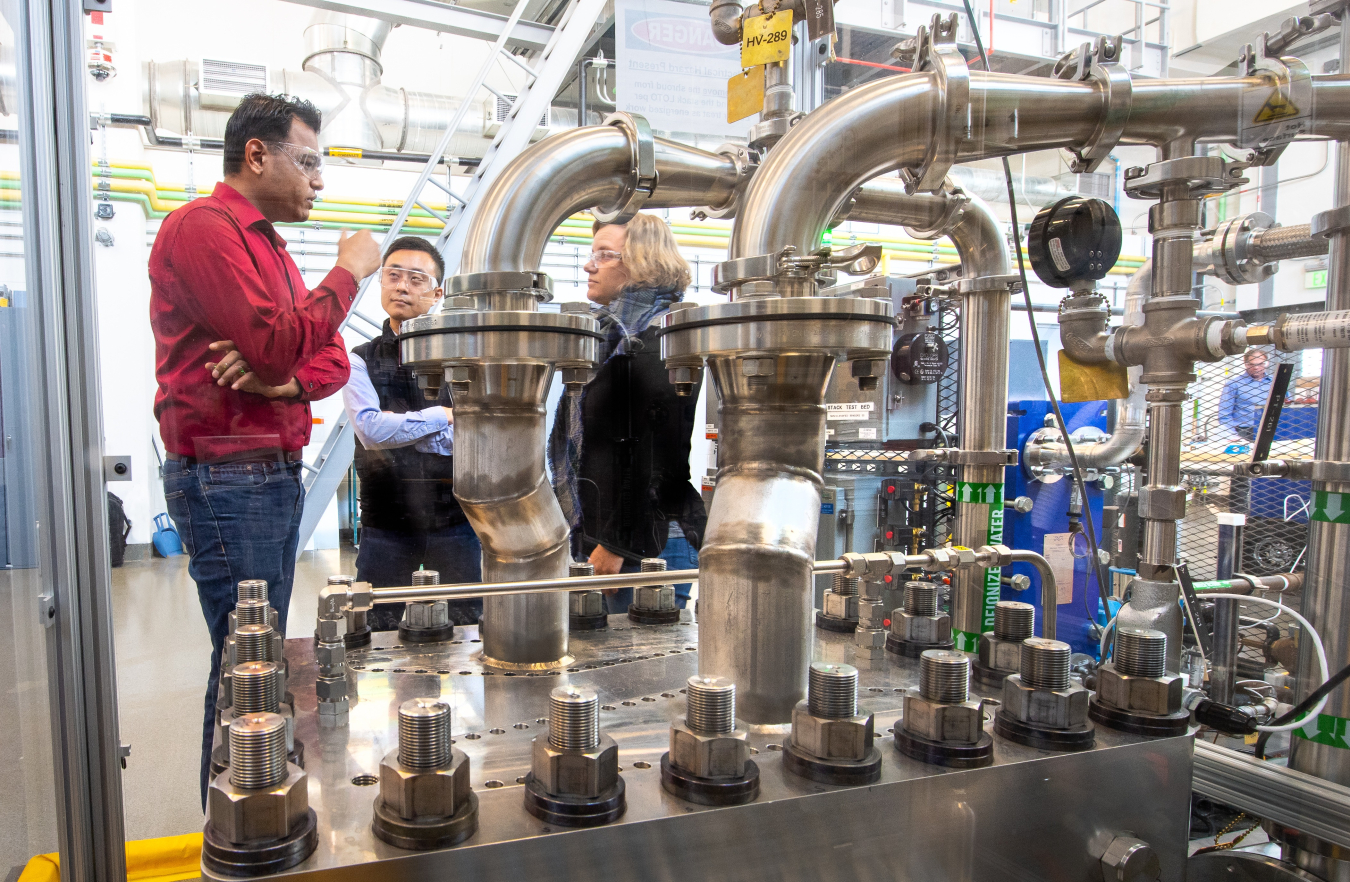

H2@Scale efforts validated, for the first time, the ability of hydrogen electrolyzers to dynamically respond to voltage disturbances.[3] This flexibility allows energy storage systems to adapt to the variability of renewable energy sources while meeting energy demands. Electrolyzers can also make use of excess renewable electricity during times of low demand, ultimately increasing renewable energy utilization and lowering the cost of hydrogen. And hydrogen can be used as a form of energy storage for renewables, either feeding power back to the grid or using hydrogen as a fuel or feedstock for other applications.

5. H2@Scale is supporting efforts to help cut the cost of hydrogen production.

Over the past few years, H2@Scale has overcome technical barriers to enable efficient and affordable production of hydrogen. R&D advancements have reduced the cost of hydrogen production from electrolysis to $5–$6/kg hydrogen at electricity costs of $0.05 to $0.07/kWh.[4] Nevertheless, there is more work to do to reach DOE’s target cost of $2/kg hydrogen. A new National Lab consortium will focus on achieving large-scale, affordable electrolyzers. These electrolyzers use electricity to split water into hydrogen and oxygen, and can be powered by various energy sources, including natural gas, nuclear, and renewables. This research will complement the existing H2@Scale work to develop efficient hydrogen production materials and methods, infrastructure, and end-use technologies.

Footnotes

- [1] https://www.hydrogen.energy.gov/pdfs/16015_current_us_h2_production.pdf

- [2] https://www.anl.gov/esia/light-duty-electric-drive-vehicles-monthly-sales-updates

- [3] https://www.hydrogen.energy.gov/pdfs/review19/ta015_hovsapian_2019_o.pdf

- [4] https://www.hydrogen.energy.gov/pdfs/19009_h2_production_cost_pem_electrolysis_2019.pdf

Sunita Satyapal

Sunita Satyapal is the Director for the U.S. Department of Energy's (DOE's) Hydrogen and Fuel Cell Technologies Office and coordinates activities across offices for the U.S. DOE Hydrogen Program. She is responsible for more than $1.6 billion in hydrogen and fuel cell research, development, demonstration, and deployment (RDD&D) activities within the office and for coordinating more than $9.5 billion in hydrogen activities across DOE. In addition, she led the development of the national clean hydrogen strategy and roadmap and serves as the Director for the Hydrogen Interagency Taskforce, which includes a dozen agencies and is co-chaired by the Deputy Secretary of Energy and the White House Deputy National Climate Advisor. She has more than two and a half decades of experience across industry, academia, and government, including at United Technologies managing RDD&D and business development, and as a visiting professor.

Sunita also coordinates international hydrogen activities as Vice-Chair of the International Partnership for Hydrogen and Fuel Cells in the Economy, a partnership among over 25 countries to accelerate progress in hydrogen and is the U.S. co-lead for hydrogen efforts within the Clean Energy Ministerial and Mission Innovation. She received her Ph.D. from Columbia University and did postdoctoral work in Applied and Engineering Physics at Cornell University. She has numerous publications, including in Scientific American, 10 patents, and several recognitions including a Meritorious Presidential Rank Award in 2015, a Distinguished Presidential Rank Award in 2022, and selected as an Ambassador for C3E, the Clean Energy Education & Empowerment Initiative, to advance the leadership of women in clean energy.

Vanessa Arjona

Vanessa Arjona is an operations manager in the Hydrogen and Fuel Cell Technologies Office (HFTO). In her role, she oversees communications, outreach, and international collaboration projects to increase understanding and awareness of hydrogen and fuel cell technologies, including their role supporting a clean and sustainable energy future for all Americans.

Born and raised in Colombia, Vanessa moved to the U.S. as a teenager with her family but has spent most of her life in Washington D.C. She is a graduate of the George Washington University’s Environmental & Energy Management Program in the School of Engineering and Applied Science.

When Vanessa is not in the office, she is likely planning the next trip to a new country alongside her husband, teaching a dance cardio class in Bethesda, or running on the Capital Crescent Trail.