Innovative Process and Materials Technologies

Advanced Manufacturing & Industrial Decarbonization

March 31, 2016

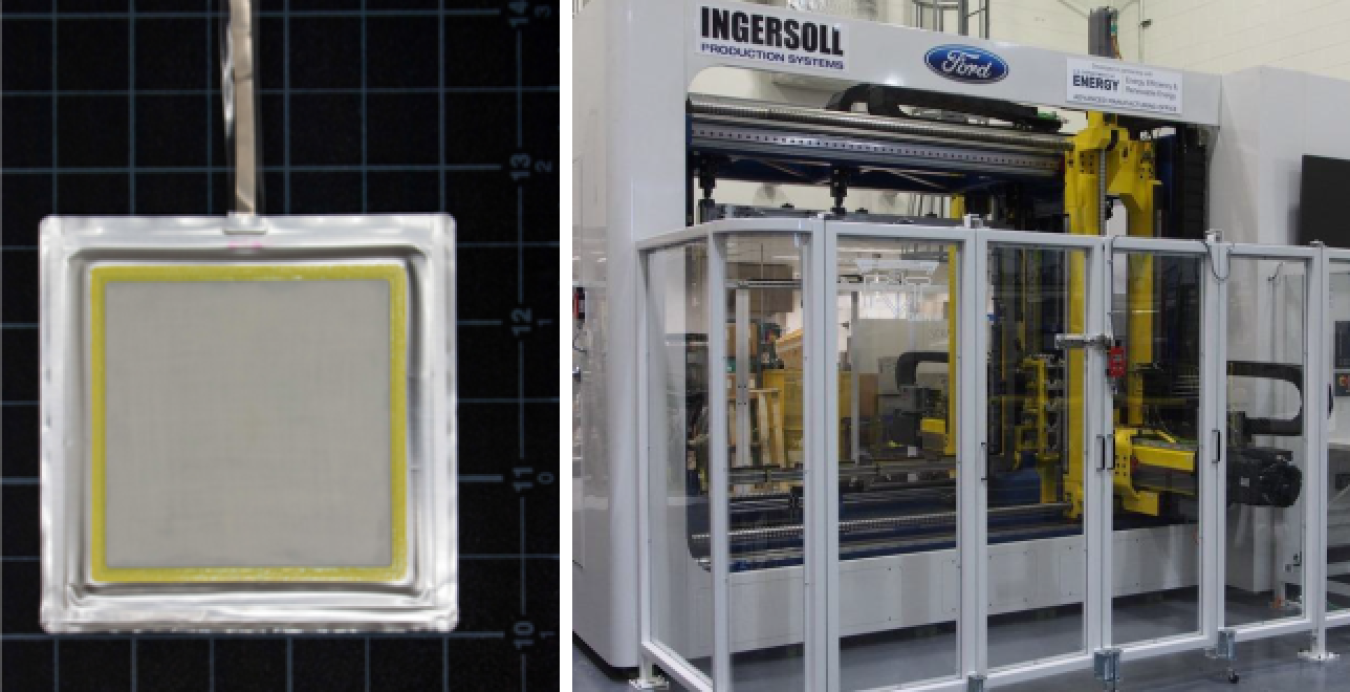

R&D Projects support the development of a wide range of processes and technologies, including (left) development of a manufacturing process for, and commercialization of, advanced Protected Lithium Electrodes (image courtesy of PolyPlus Battery Company); and (right) the design, build, and commissioning of a RApid Freeform sheet metal Forming Technology (RAFFT) that eliminates stamping and forming dies that will enable rapid prototyping for vehicle parts (image courtesy of Ford Motor Company).

INNOVATIVE PROCESS AND MATERIALS

U. S. industry consumes approximately 30 quadrillion Btu (quads) of energy per year, which is almost one third of all energy used in the United States. Solutions that increase energy productivity (output per unit of energy used) within industry are needed to ensure that U.S. producers lead the world in modern production technologies. Innovative manufacturing process technologies and materials can help reinvigorate existing manufacturing industries while supporting the growth and development of clean energy technologies and new industries in the United States.

R&D projects support the development of innovative manufacturing processes and materials technologies to advance the clean energy economy by:

- Increasing industrial and manufacturing energy efficiency

- Delivering the breakthroughs that the nation needs to significantly reduce energy and carbon intensity throughout the economy over the coming decades

- Revitalizing existing manufacturing industries and supporting the development of new products in emerging industries

View the project portfolio and associated fact sheets:

A Novel Flash Ironmaking Process

Advanced, Energy-Efficient Hybrid Membrane System for Industrial Water Reuse

Scale-Up of Novel Low-Cost Carbon Fibers Leading to High-Volume Commercial Launch

Continuous Processing of High Thermal Conductivity Polyethylene Fibers and Sheets

Innovative Manufacturing of Protected Lithium Electrodes for Ultra High Energy Density Batteries

High Metal Removal Rate Process for Machining Difficult Materials

Rapid Freeform Sheet Metal Forming: Technology Development and System Verification

Conversion of Waste CO2 and Shale Gas to High Value Chemicals

No Heat Spray Drying Technology

Novel Membranes and Systems for Industrial and Municipal Water Purification and Reuse

A Novel Unit Operation to Remove Hydrophobic Contaminants

Low-Energy, Low-Cost Production of Ethylene by Low-Temperature Oxidative Coupling of Methane

Coatings and Process Development Reduced Energy Automotive OEM Manufacturing

Low-Cost Bio-Based Carbon Fiber for High Temperature Processing

Energy Efficient Thermoplastic Composite Manufacturing

One Step Hydrogen Generation through Sorption Enhanced Reforming

High Thermal Conductivity Polymer Composites for Low Cost Heat Exchangers

No Heat Spray Drying Technology

Novel Membranes and Systems for Industrial and Municipal Water Purification and Reuse

A Novel Unit Operation to Remove Hydrophobic Contaminants

Low-Energy, Low-Cost Production of Ethylene by Low-Temperature Oxidative Coupling of Methane

Coatings and Process Development Reduced Energy Automotive OEM Manufacturing

Low-Cost Bio-Based Carbon Fiber for High Temperature Processing

Energy Efficient Thermoplastic Composite Manufacturing

One Step Hydrogen Generation through Sorption Enhanced Reforming

High Thermal Conductivity Polymer Composites for Low Cost Heat Exchangers