Tereform is a Denver-based startup on a mission to enable circularity within the fashion and textile industries. The startup is developing a novel chemical strategy that can transform waste textiles into the chemical building blocks they were made from.

Office of Technology Transitions

August 28, 2023Energy I-Corps Success Story

Introduction

Tereform is a Denver-based startup on a mission to enable circularity within the fashion and textile industries. The startup is developing a novel chemical strategy that can transform waste textile materials, such as polyester, back into the chemical building blocks they were made from for reuse.

The founders, Mikhail Konev and Kevin Sullivan, researchers out of National Renewable Energy Laboratory (NREL), began their entrepreneurial journey through the Office of Technology Transitions (OTT) Energy I-Corps program in 2021. During Cohort 13’s two-month curriculum, funded by the Department of Energy’s Bioenergy Technologies Office, they pivoted several times before landing on the textile recycling problem they’re solving today.

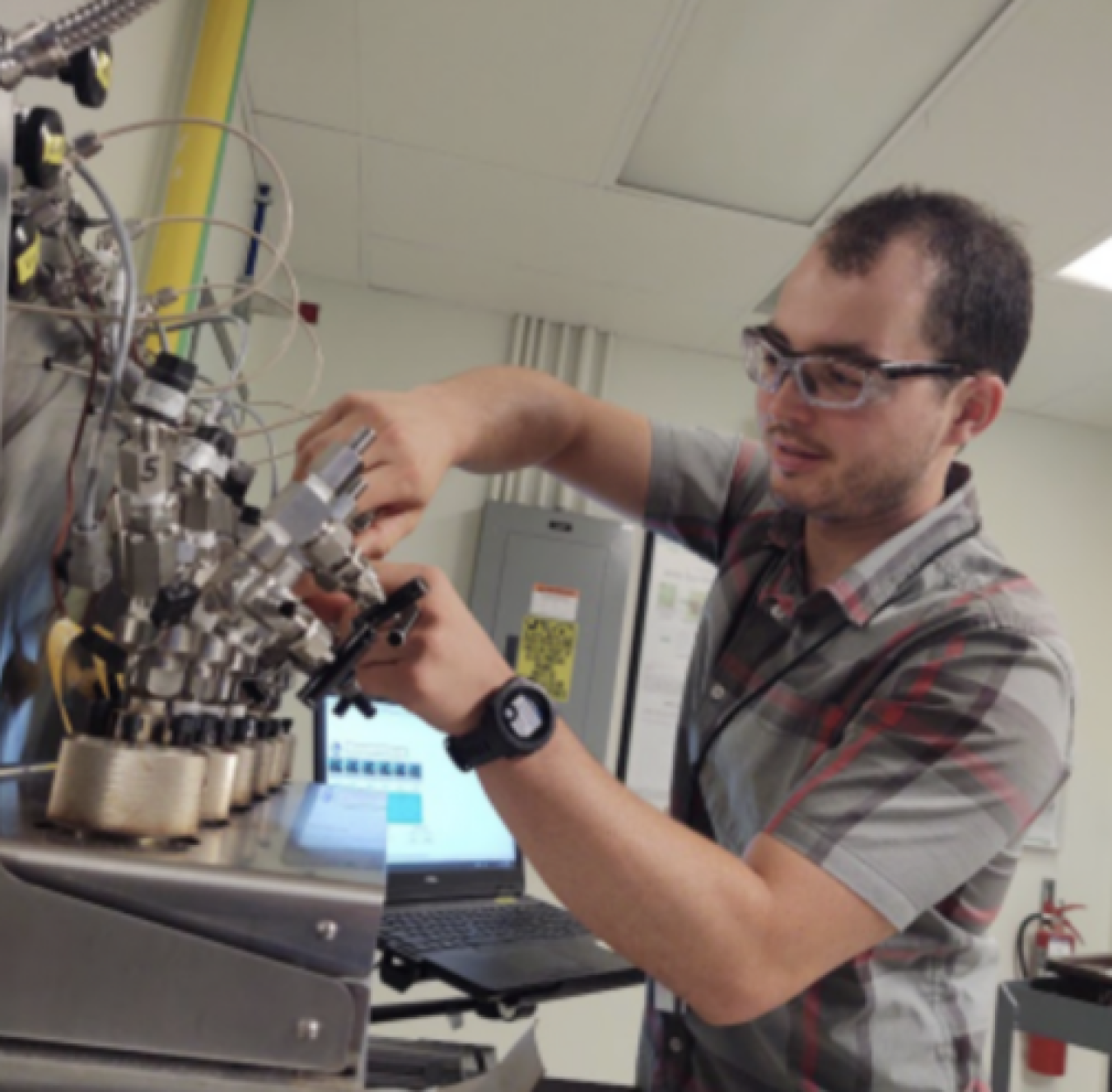

Mikhail and Kevin founded Tereform after graduating from Energy I-Corps and Mikhail has since applied for and was accepted into NREL’s West Gate program. West Gate is a two-year Lab-Embedded Entrepreneurship Program where the company can continue to leverage NREL’s lab space and R&D resources while participating in entrepreneurial training and business mentorship. The close ties to NREL through West Gate allow the company to further prove out the technical pathways identified during Energy I-Corps while establishing their roots in the startup community. Tereform recently won the H&M Foundation’s 2023 Global Change Award and is currently in discussions with several potential brand partners.

Today, we are catching up with Tereform’s co-founders, Kevin Sullivan, CEO, and Mikhail Konev, CTO, to learn more about the milestones they have achieved since going through the Energy I-Corps program.

Q&A with Kevin Sullivan (KS) and Mikhail Konev (MK)

OTT: Tell us about the origin story of Tereform. What are your backgrounds and how did you come together?

MK: My background is in organic chemistry with a specific focus on discovering and developing reactions by using metal catalysts to create new chemical bonds. After grad school, I worked at a large pharmaceutical company where I built complex molecules using this skill set. While doing this work, I began to think if I can do this, I can also break down pollutants. I then joined NREL in 2020 and met Kevin when we were working on biomass and plastic depolymerization.

KS: I have a background in inorganic chemistry that was all about using oxygen to break things down. In grad school, I worked on the decontamination of chemical warfare agents and other toxic compounds. That brought me to NREL in 2019 where we were trying to use oxygen to break down biomass. As we were doing that, we found that it applied very well to plastics, so Mikhail and I developed this project around breaking down hard-to-recycle plastics with oxygen, which led to a larger effort focusing on mixed plastics.

OTT: Tell us about the problem you’re trying to solve and how your technology solves it.

KS: Energy I-Corps helped us identify recycling as a huge challenge for textiles. Though some textile recycling strategies exist, there’s not a great way to deal with blended materials, especially if they have spandex or dyes, because these additives make the isolation and purification of the products really challenging.

Our technology can tolerate these mixed inputs by using the oxygen in air and earth-abundant metal catalysts to deconstruct waste plastics back into their original chemical building blocks for reuse. It’s based on a well-known chemical transformation that’s already carried out on a massive scale within the chemical industry, but we’re applying it to breaking down plastics with challenging additives. The idea is that once it goes through our process, you’re left with just the powdered monomers that you can reuse.

OTT: How did participating in Energy I-Corps impact the development of Tereform?

MK: Before joining Energy I-Corps during Cohort 13, we were working on mixed plastics depolymerization technology with packaging plastics, and our initial focus was Styrofoam recycling. Through customer discovery conversations, we invalidated our original commercialization hypotheses and realized the business model wouldn’t work. So, we moved on to nylons and, within a week or so, that was also dead in the water. We ended up having three major pivots during our time in Cohort 13. After we formed Tereform, we then had the opportunity to participate in Cohort 15 to further develop our ecosystem understanding with refining our product market fit. The customer discovery process and the business model canvas development were instrumental in figuring out what our business would be.

KS: We knew a lot on the lab side but very little on the application side, so going through Energy I-Corps gave us an understanding of how a business could feasibly work. Energy I-Corps was the galvanizing factor for launching this company. We conducted more than 80 stakeholder discovery interviews, through which we developed our skills interviewing people and feeling comfortable asking the right questions. If you compare the very first interview to the last, it is night and day.

OTT: What is next for Tereform?

KS and MK: Our next product milestone is scaling up the amount of material processed in a single run. We’re also thinking about future fundraising needs and bringing on more employees to help us construct an independent lab once Tereform completes the West Gate program. Finally, thanks to NREL’s Tech Transfer Office, we have obtained an option agreement that allows us to explore license opportunities. So, we are having some exciting early conversations with brand partners that we’re hoping to co-develop some IP and other sourcing materials around. Many brands are interested in being able to fully circularize a garment whether it’s with scrap materials during the production process or through a take-back program for unsellable garments.

Energy I-Corps is a key initiative of the U.S. Department of Energy's Office of Technology Transitions (OTT), which sends teams of researchers and industry mentors through an immersive two-month training where the researchers define technology value propositions, conduct stakeholder discovery interviews, and develop viable market pathways for their technologies. To learn more, visit energy.gov/technologytransitions/energy-i-corps

To learn more about Tereform, please visit www.tereform.com.