Team ducted fuel injection participated in Cohort 13 and has since advanced their technology readiness level through a Technology Commercialization Fund award and formed a CRADA from partners from Energy I-Corps.

Office of Technology Transitions

September 27, 2024Diesel fuel, used to fuel vehicles, heavy machinery, and generators, produces harmful emissions like particulate matter (soot) and nitrogen oxides when burned. This Energy I-Corps team, funded by the U.S. Department of Energy’s (DOE) Vehicle Technologies Office, focused on lowering harmful emissions from diesel engines. The DOE Office of Technology Transitions’ Energy I-Corps program offers an intensive, 2-month commercialization training to National Laboratory teams to set their clean energy technology up for a successful market launch. Team ducted fuel injection (DFI) participated in Cohort 13 and has since advanced their technology readiness level through a Technology Commercialization Fund (TCF) award and formed a CRADA from partners from Energy I-Corps.

DFI technology for diesel engines can be understood by considering a Bunsen burner. When the tube is removed from a Bunsen burner and lit, a tall orange flame appears due to soot produced during combustion. However, attaching the tube and maintaining the same gas flow rate results in a short blue flame.

“The flame is blue because it’s not producing any soot,” said Chuck Mueller, a distinguished member of the technical staff at Sandia National Laboratories (SNL). “Inside today’s diesel engines, four to nine sprays inject fuel directly into the combustion chamber, like Bunsen burners without their tubes attached. DFI transforms those sprays into Bunsen-like flames, resulting in substantially lower soot emissions.”

Mueller says improving diesel engines is important because they are used in many applications that face major challenges on the path to lower lifecycle carbon dioxide (CO2) emissions. For example, heavy-duty off-road equipment, locomotives, and ships often operate in locations where recharging infrastructure does not exist. Therefore, if these applications did want rechargeable energy, they would need massive battery packs that are expensive and the production of which would result in the release of huge amounts of CO2. DFI technology is a promising alternative.

“We need to use all the tools we have to mitigate climate change,” Mueller said. “Where electrification isn’t practical, we can switch to fuels with lower lifecycle CO2 emissions, such as those made from plants or from CO2 captured from the atmosphere.”

Mueller brought SNL’s DFI technology to Energy I-Corps in 2021 with funding from DOE’s Vehicle Technologies Office and values the experience. The program offers two months of intensive commercialization training to ensure a technology’s successful launch to market.

“It’s a crash course in starting your own business,” he said. “Not only learning about the business aspects of getting your technology into the market, but also making connections with others in the energy ecosystem that enable you to move forward.”

Those connections made a huge difference in the trajectory of the DFI technology. Each Energy I-Corps team gets assistance from an industry mentor, and the DFI team’s mentor was from John Deere, known for its agricultural and construction vehicles. As part of Energy I-Corps, participants must interview at least 75 people from the technology’s ecosystem to learn more about the possible demand and pathway for commercialization.

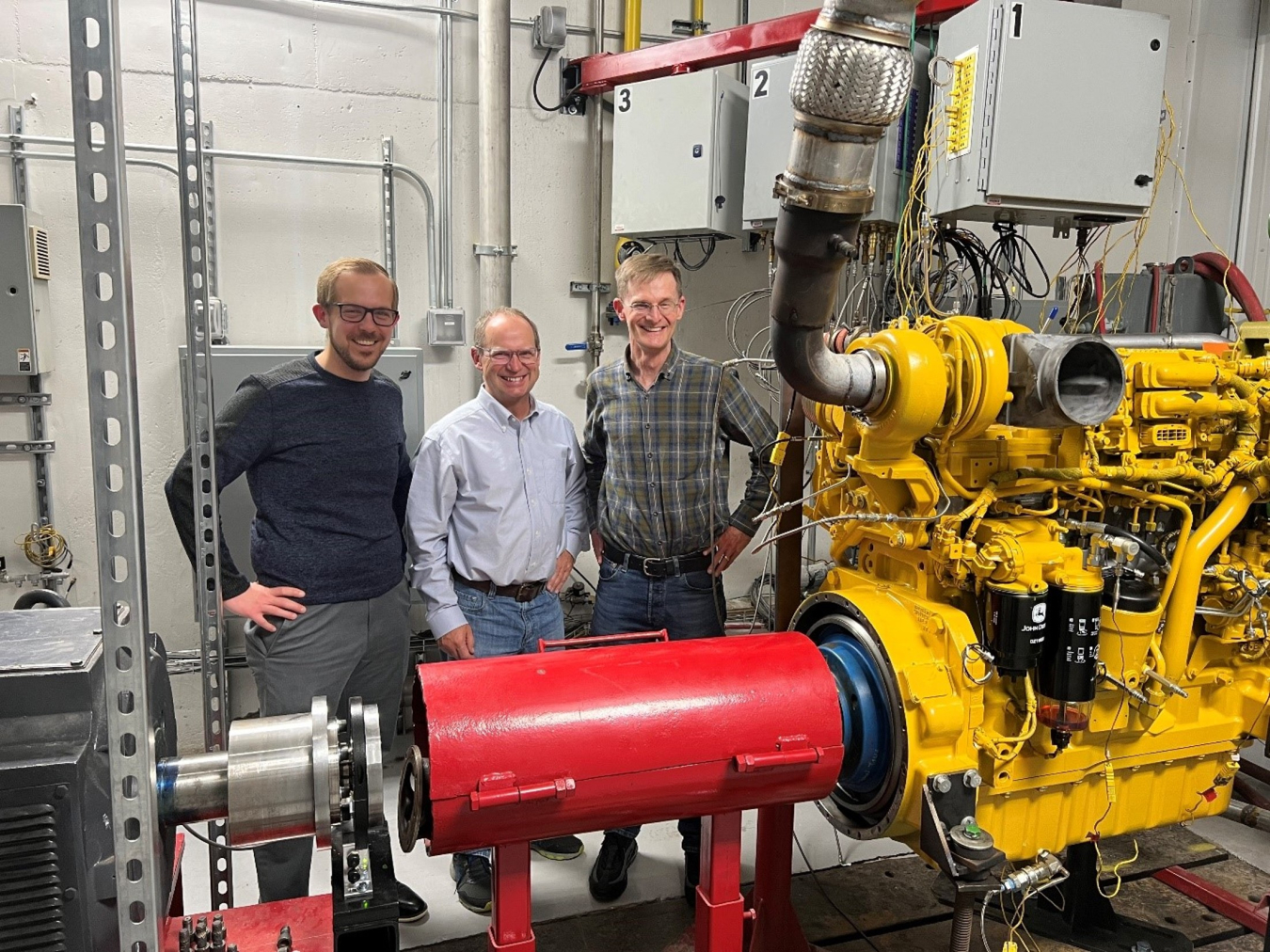

A year after graduating from the program, Mueller and Entrepreneurial Lead, Kirby Baumgard successfully assembled a team including John Deere, Cummins, the Coordinating Research Council, and Clean Fuels Alliance America. They signed a cooperative research and development agreement (CRADA) to create a DFI research consortium that now has 20 participating organizations.

“We’ve been moving DFI up the technology readiness level ladder,” Mueller said. “We’ve been focused on testing it for the first time in a multi-cylinder engine from John Deere. What we’ve recently found is that DFI gives us 65% lower soot, 50% lower nitrogen oxides, and 70% lower lifecycle CO2 emissions. This is just the first try at a production-engine retrofit—we fully expect even better performance from an optimized, dedicated DFI engine.”

The recent tests used different types of fuels, including ultra-low sulfur diesel fuel, renewable diesel, biodiesel, and a 50-50% blend of renewable diesel and biodiesel. This testing was made possible because of follow-on DOE funding: the DFI team won a three-year DOE Base Annual Appropriations TCF award in 2022, selected by VTO.

Mueller says the benefits and lessons of the Energy I-Corps program are too numerous to list.

“A big one was learning to identify the beachhead application to turn your idea into reality,” Mueller said. “It’s also been helpful in providing an overview of the whole technology commercialization process. We simply don’t get that training in graduate school as scientists or engineers.”