Mountain top photovoltaic system in Utah.

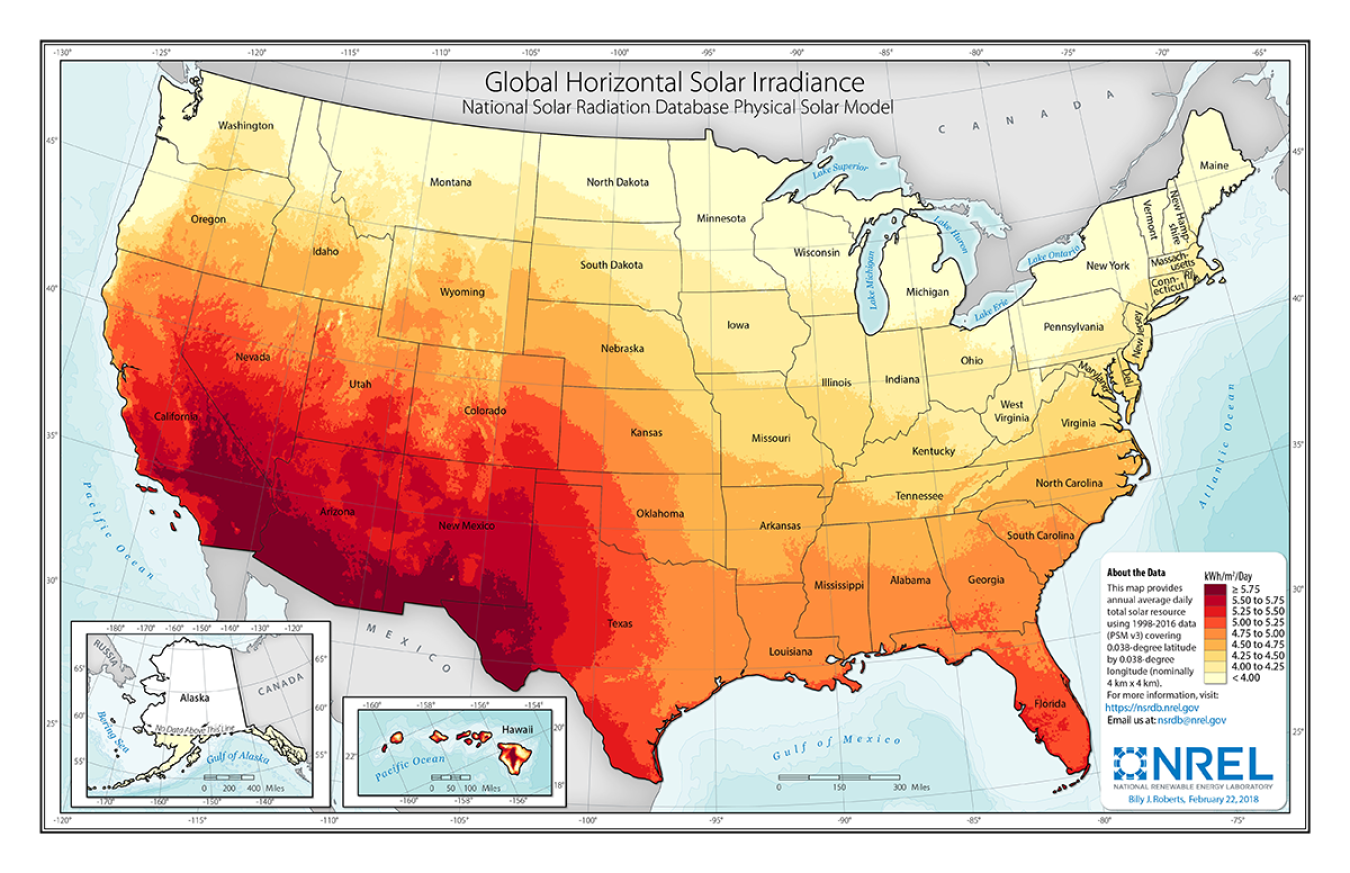

While solar photovoltaic (PV) installations are best able to reliably take advantage of the sun's energy in climates such as the Southwestern United States (Figure 1), PV systems are also beneficial in parts of the United States with severe winter weather. This page examines the areas of the United States most at risk from severe winter weather and summarizes various approaches that PV system designers, installers, owners, and operators can take to address these hazards throughout the entire PV production lifecycle, from design through post-damage repair.

Figure 1. Total solar resource availability in the United States. (Source: The National Solar Radiation Data Base)

Risk Profile

PV modules operate more efficiently in colder weather, as temperatures above 77°F cause decreases in voltage. However, the threat of winter weather, like ice and snow, pose design and operational challenges for PV systems in these areas and can limit power production.

More severe winter weather or long-term exposure to winter weather conditions can seriously disable or damage a PV system, leading to repair costs and production losses if the system is not designed to withstand these conditions.

Most snow will melt quickly off PV systems or be blown off by wind. Heavier snow or extreme winter weather, however, pose a greater risk to the resilience and longevity of PV installations. During severe snowstorms, the weight of accumulated snow on a PV module may cause it to warp or even break.

Similarly, the formation of ice upon the surface of a PV system can both add to and significantly redistribute the weight of the system, potentially over-straining certain components such as the module frames and the structure supporting the system from below.

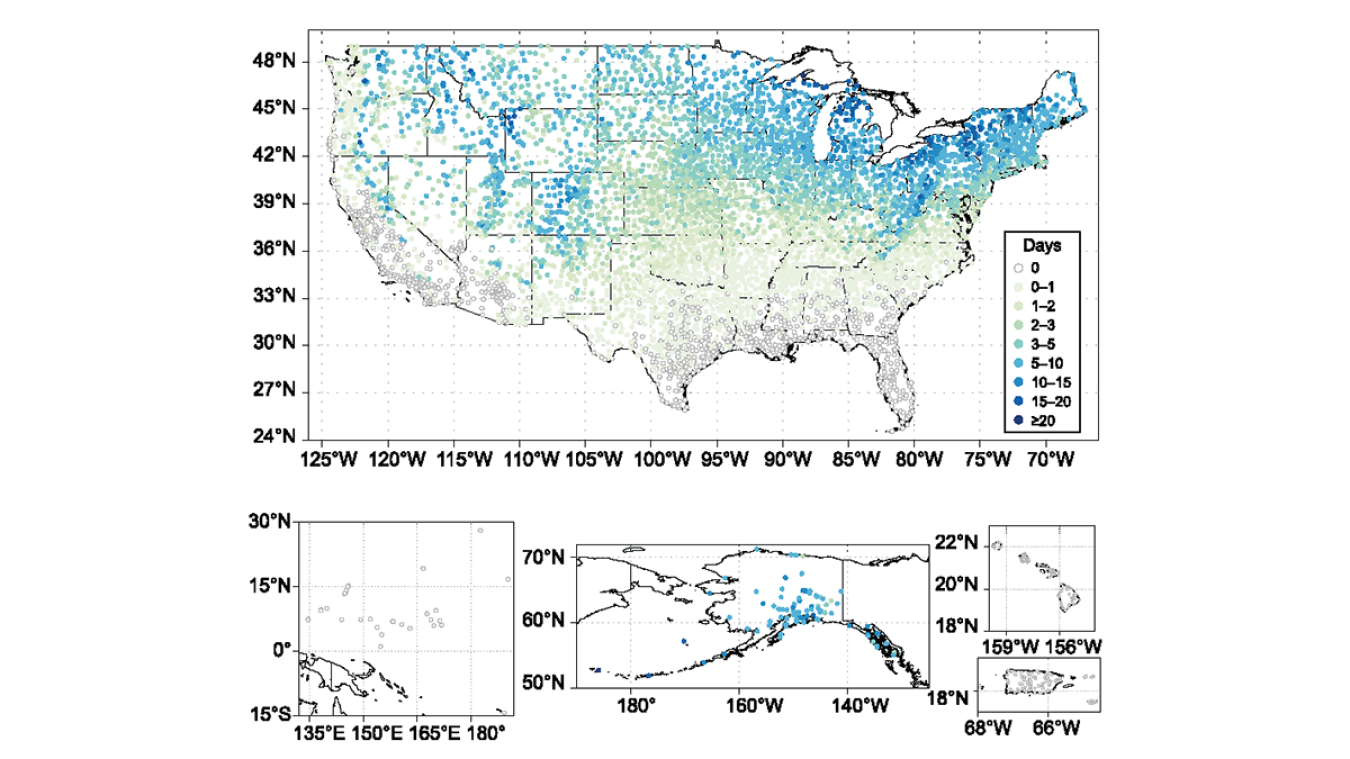

The majority of the United States is subject to snow conditions or some degree of winter weather hazard that could damage or interrupt the operation of a PV system (Figure 2). Generally, historical data from the last three decades show that although snow falls throughout the nation, the areas that receive the deepest January snowfalls (i.e., average of more than 30 inches) during that time range have generally been in sections of 18 states, including:

- Mountainous or high-elevation areas (e.g., Blue Mountains, Cascade Ranges, Colorado Plateau, Columbia Plateau, Independence Mountains, Markagunt) in all states west of or containing the Rocky Mountains, except Arizona

- Great Lakes-facing coasts of Michigan and Wisconsin

- Areas of Appalachia in West Virginia

Figure 2. Average total January snowfall in inches in the United States from 1981 to 2010. (Source: National Oceanic and Atmospheric Administration)

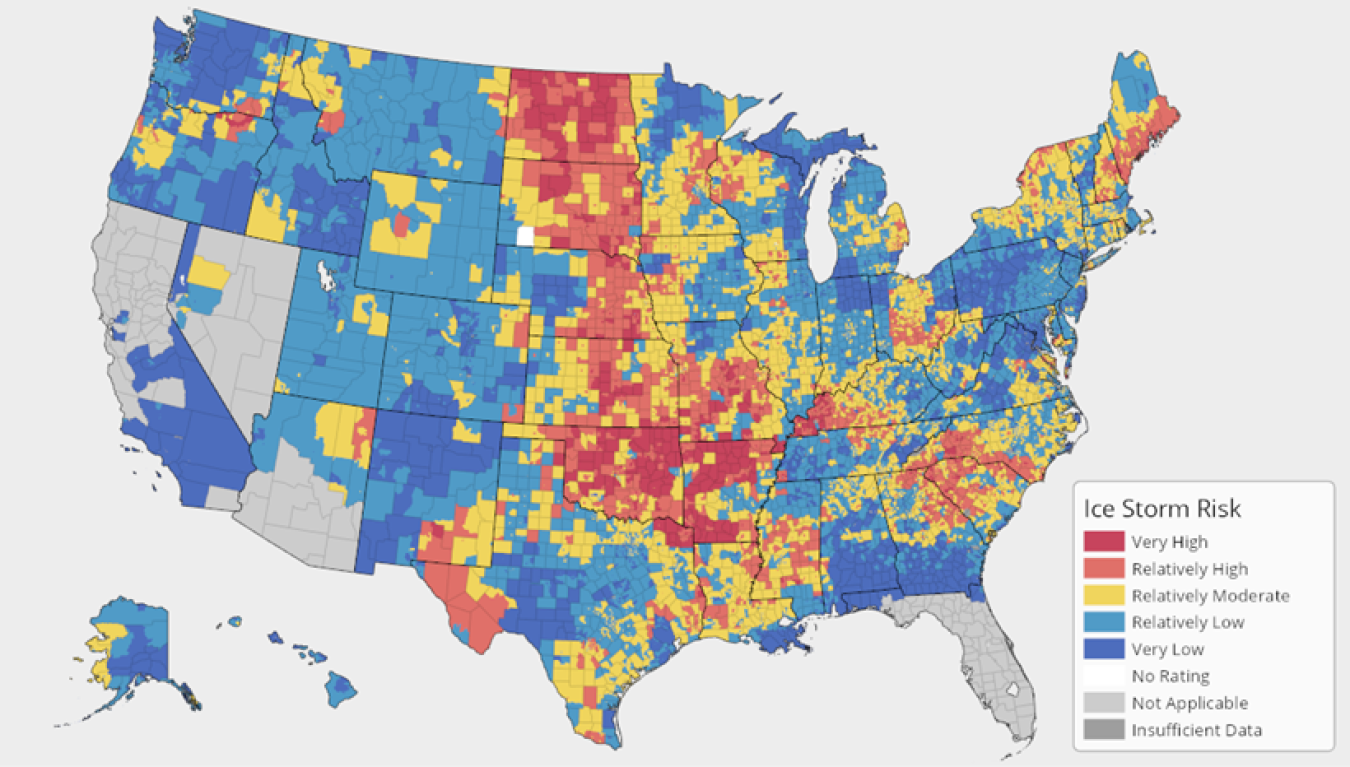

The geographic distribution of the risk of ice storms is significantly different from the geographic distribution of snowfall depth. Figure 3 shows ice storm hazard risk across counties.

The places most at risk from ice storms are sections of the Great Plains region, including Kansas, Nebraska, North Dakota, Oklahoma, and South Dakota; as well as some parts of the Southern United States, including sections of Arkansas, Kentucky, Missouri, and Texas; and other isolated counties.

This risk of ice storms pertains more to areas with relatively flatter topography, compared to the risk of heavy snowfall accumulation, which pertains mainly to high-elevation areas and high-latitude locations.

Figure 3. Risk of ice storm hazards in the United States by county. (Source: National Risk Index)

This distinction is crucial as snow and ice adhere to PV systems in different ways and require specific solutions. Anti-snow PV coating applications need to address water that is already frozen whereas anti-ice PV coating applications need to first prevent precipitation from freezing on its surface and then convey it quickly off the system.

Best Practices

This section outlines measures to prevent damage to PV systems and increase production in areas at risk for extreme winter weather. These include considerations in the design, procurement, and installation phases of the project as well as during the performance period (including after a winter weather hazard has occurred).

System Design and Procurement

It is crucial to design a PV system to survive the conditions it will experience over its expected lifetime (typically 25–30 years). System design encompasses module selection, racking parameters, attachments of modules to the racking or roof, system layout, and foundation design.

Module Selection

Modules are tested for how much load they can withstand and are typically certified according to the test standard IEC 61215. Load ratings are typically given in Pascals (Pa). A typical module rating will be 2400 Pa.

For locations at risk of heavy snow accumulation, select modules certified to withstand at least 5000 Pa. Refer to module installation manuals to find static (snow) test load ratings for the specific mounting configuration to be used. Adding mounting points can also increase the load rating. Smaller modules can typically withstand higher loads.

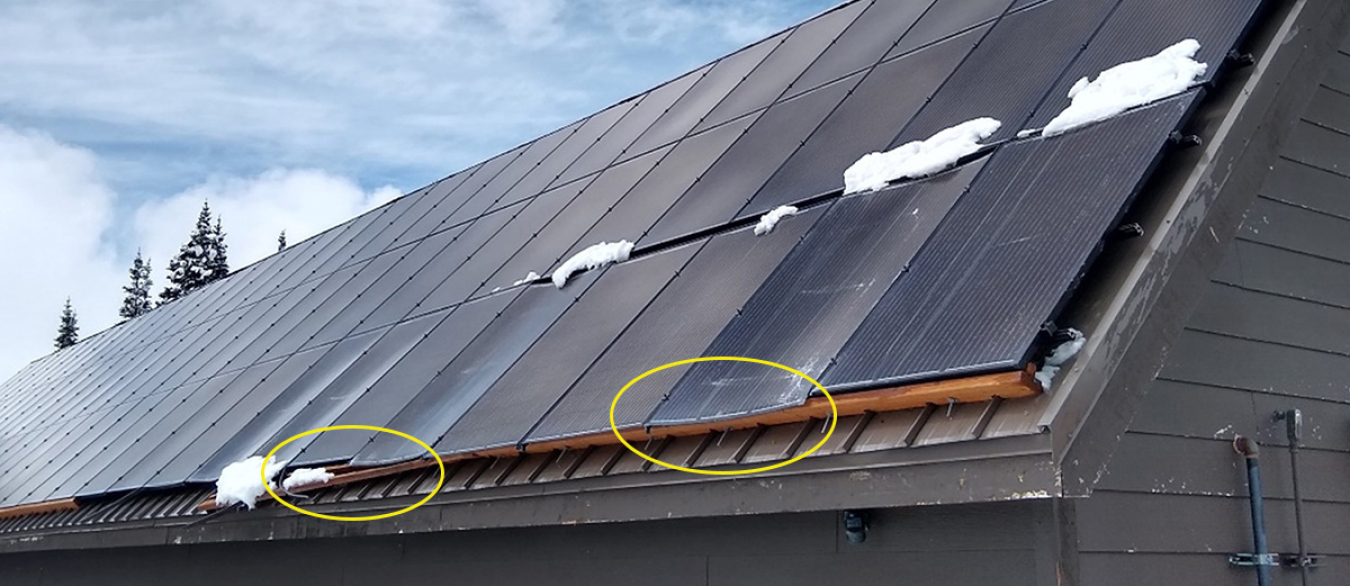

Because PV modules are normally installed in a tilted position, snow will slide down the panels and accumulate unevenly at the bottom edge of the panel at the frame (see Figures 4 and 5 under the section, "Framed Versus Frameless"), resulting in greater stress on the lower portion of the module. IEC standard 62938 for framed modules provides a method to determine the load-bearing capability of modules subjected to non-uniform snow loads.

Snow loads for a specific site are typically calculated using ASCE 7 that result in a ground snow load in pounds per square foot (psi). These ground snow loads are used in formulas which factor in site specifics to yield a roof snow load for rooftop systems.

When calculating loads, do not assume a uniform loading across a PV system; factor in that the lower side of the modules typically gets loaded more than the higher side, causing increased stresses on the module.

Modules typically have metal frames around the perimeter of the PV module, though some modules are frameless.

Frameless modules can shed accumulated snow more quickly since the frame can prevent snow at the lower tip of the panel from sliding off after a heavy snowfall. Frameless modules, however, may have lower snow and wind load ratings than framed modules. Load rating should be the priority consideration over the ability to shed snow.

Figure 4 shows the success of the PV systems without the frame after a snowfall along with framed PV systems that have retained more snow.

Figure 4. Framed (background) and frameless (foreground) solar PV systems with differing snowfall retention.

Photo Courtesy of Sandia National LaboratoriesUnder heavy snow weight and ice buildup, frames have come detached from modules as well (Figure 5).

Figure 5. Frames detached from modules after severe winter weather.

Photo from Aaron Bougie, NPS.Under heavy loads, invisible cracks can form in solar cells. Modules with multi-busbar solar cells have a lower risk of propagating these cracks. The solar cell width between the busbars on multi-busbar PV panels has a smaller surface area than traditional busbar technology and so cracks have limited room to grow. If cell cracks grow, they can lead to decreased production and possibly fire safety risks.

Coatings and treatments for PV systems that would facilitate the automatic removal of snow and ice from the surface of the system are currently under development and are not mature at the time of writing.

System Considerations

Higher tilt angles allow snow to shed from systems more quickly and reduce the risk of damage. The steeper the angle, the better the snow shed (up to 60 degrees).

Significant gains are seen around 30–35-degree tilt angles, which is significantly steeper than a typical roof. Furthermore, the steeper the module tilt angle, the less snow weight is transferred to the module.

Selecting a higher tilt angle, however, will result in higher wind loads on modules, and thus higher costs, so the system designer should find the ideal compromise between these drivers as well as solar production.

PV tracker systems can adjust their angle with respect to the ground. If installing a tracker system in a heavy snow region, select one with the capability of a "snow stow" mode that will tilt the panels to a steep angle in a heavy snow event, thus aiding shedding of snow off the modules. This can be engaged manually or automatically.

This functionality may not be available in heavy snow events, especially if communication with the system is lost. Ensure the system designer designs for the worst-case scenario where the tracker is not able to stow or shed any snow.

Overall, tracker systems typically mount modules closer to the center of the module, leaving the ends less supported. If installing a tracker system, ensure that module load calculations are performed using the actual attachment points on the module, rather than simply using load ratings given on a specifications sheet.

Snow that has fallen or been shed from a PV system may accumulate on the ground. In areas prone to heavy snowfall, elevate the bottom edge of systems higher above ground to accommodate, at least two feet above maximum normal snow depth. This will have cost implications and increase the wind load, so it is important to weigh these factors and risks.

A greater number of attachment points on a module could increase its ability to withstand heavy snow loads. Modules typically use four attachment points, though more are possible.

A National Park Service site in Mount Rainier National Park had a harsh winter that left modules crushed. They replaced the damaged modules (that were attached at four points) and racking with new modules that attached to the racking at eight attachment points. They also added extra module supports underneath the modules. These retrofits survived the following winter without damage.

Read more about the successful deployment of a solar power system at Mount Rainier National Park.

As ground in cold climates freezes and thaws, foundations on structures can work their way up out of the ground. This can cause damage to or even toppling of a ground-mounted PV system.

Consideration of frost heave is not always required on projects and is not mandated in ASCE 7 building codes that are typically used, so require design engineers to account for frost.

Ensure frost depth is considered in the design, type, and depth of foundations; the pile depth should extend significantly below the frost depth. Guidance for calculating frost heave forces is provided in Newson, 2022.

Use a design engineering firm with experience and success installing PV in cold weather climates and require that they perform frost heave calculations in the system design. Soils vary from site to site and can vary across a site so design foundations for the specific conditions present. This may require a pile pull test.

Orienting PV modules in landscape format can help accelerate shedding of snow or ice that is covering a PV panel. This orientation will also increase production as snow typically melts and first exposes the tops of the modules. The PV module produces power from three discrete sections: when viewed in landscape this would be the top third, middle third, and lower third. When each of these thirds of the module are clear of snow, they can produce power.

In areas where the wind generally blows from a single direction, PV system operators can take advantage of the venturi effect, where a current of fast-moving wind crests over the top of a sloping obstacle and then speeds away from the object. For PV systems, installing a curved "venturi" deflector at and pointing the top of the PV panel against the direction of the wind can help ensure that snowdrifts or water-bearing winds do not make contact with the surface of the panels, reducing the risk of snow or ice accumulation.

Vertical PV installations are fixed at a 90-degree angle relative to the horizon. Not only are they less likely to accumulate snow or ice compared to horizontally tilted systems but any snow or ice that ultimately adheres is more likely to shed off the panel.

At high latitudes, their extreme orientation also means that they can capture the low angle of the winter sun more effectively.

Ground-mounted vertical PV can be placed in areas that would otherwise be infeasible for ground-mounted horizontal PV since the vertical PV uses space more efficiently and may be placed among existing land uses, such as parking or farmland.

Wind loading, though, will be higher on vertically mounted PV systems, which needs to be weighed against the benefits of a vertical PV system.

- Avoid systems with substantial cantilevers.

- Thicker and deeper frames around modules could increase the load capacity of the module and help prevent glass breakage.

- Thicker gauge racking will give a more robust structure more likely to withstand heavy snow and ice loads.

- More spacing between modules or between "tables" of modules can possibly give snow more space to shed, aid melting, and break up large masses of snow accumulation.

- Consider combined snow and wind loads in the design as these hazards often occur together.

- Avoid systems with substantial cantilevers.

Ice Load

Categorize solar racking as "ice-sensitive structures" as defined by ASCE 7. This will require design to account for ice buildup on the racking structure. For roof-mounted systems, have modules situated up to the top of the roof and include a barrier to prevent ice dam build up.

Figure 6. Water ingress frozen inside an electrical enclosure.

Photo from Matt Piantedosi.While always important to keep water out of electrical components, water ingress can pose additional risk in cold weather climates. Water that enters an electrical enclosure can freeze and expand, damaging system components (Figure 6). Enclosures should be NEMA 4 or higher rated.

As snow melts and freezes, it can form icicles on a PV system. Icicles can add weight and pull on light system components such as wiring, so use wire management solutions that will hold under added weight. Do not use plastic wire ties and ensure wire connections are under modules or otherwise protected from where icicles will form.

Operations and Maintenance

Risk Planning

Development of a hazard mitigation plan that accounts for winter weather hazards can help reduce the overall impacts of ice storms, heavy snow, and frost upon PV systems. Having a post-hazard recovery plan in place when a winter weather hazard occurs will help ensure that the PV system can quickly resume power generation with minimal cost. The plan should:

- Identify roles and responsibilities for various parties involved in the PV system's operations, their expertise and capacity for addressing the hazard, and applicable funding sources to implement the plan.

- Identify actions for repairing the damaged PV system, the responsible actors for repairing the PV system, and funding sources they can use to absorb the costs of repair.

In situations where many feet of snow bury a PV system, avoid the potential for accidental damage (e.g., stepping on the glass surface of the PV panel or damaging it with snow removal equipment) by installing poles several feet in height along the corners and perimeter of the system and signage to alert crews of the presence of a PV system.

These poles can help snow removal workers identify the system's location and avoid damaging the system. This is especially important in systems adjacent to parking lots or roads where snowplows may inadvertently damage a PV system (Figure 7).

Figure 7. A solar PV system damaged by a snowplow. Perimeter marking and signage around the system could have prevented this.

Photo from Andrew Oddo, USMC.Removal of accumulated snow or ice is not recommended. If attempted, it should be done with extreme caution and care.

Shovels can cause damage and attempting to remove snow off panels can do more harm than good. Stepping or standing on panels will cause damage, and crews are often not aware of these risks or may unintentionally put weight on panels.

If snow accumulation is excessive and a site chooses to remove snow, use softer tools, such as brooms and brushes to remove snow above the panels.

Pre-Storm Best Practices

In the event of an impending severe storm, system survival should take precedence over power production. Power production is likely to be minimal during a storm, regardless, and damage could lead to system downtime for extended periods that would be far more costly.

- Remove existing snow from panels only if there is substantial existing accumulation on top of panels and a risk of overloading with the incoming storm. If needed, gently remove snow using a broom and not a shovel.

- Remove snow from the ground or roof around the system to allow snow shedding.

- Ensure communication with system is intact, especially for tracker systems.

- Power down system and inspect after the storm before powering back on.

- If the system is connected to an energy storage system like a battery, fully charge the battery.

- If accessible, ensure gutters and drainage systems are clean.

Post-Damage Techniques or Practices

In locations prone to extreme winter weather, a trained professional should inspect the system after each winter season or after an extreme weather event. Visually check for broken glass, detached metal module frames, warped modules.

If the system is easily accessible, ensure modules are still securely attached to the racking or roof. Visually check that electrical cables are still routed securely and attached. Check that energy production of the system is as expected.

If damage is detected, the system should be disconnected and corrective repairs should be made, including replacing damaged modules.

Quick Links

Need Assistance?

Contact FEMP for assistance with solar PV systems.