Mount Rainier National Park collaborated with the National Renewable Energy Laboratory and the U.S. Department of Energy's Federal Energy Management Program to install, and later retrofit, a solar photovoltaic (PV) system at park facilities used by staff and visitors. The site, known as Sunrise, is located at the highest location in the park and is prone to extreme winter weather.

This case study highlights measures taken to implement renewable energy technologies and energy conservation measures, as well as improvements after extreme snow caused damage to the solar photovoltaic system.

ON THIS PAGE

The solar photovoltaic system saves the site almost 12,000 gallons of fuel a year, cutting use by 91% for a remote, off-grid site. Retrofits have helped the system survive extreme winter weather.

Background

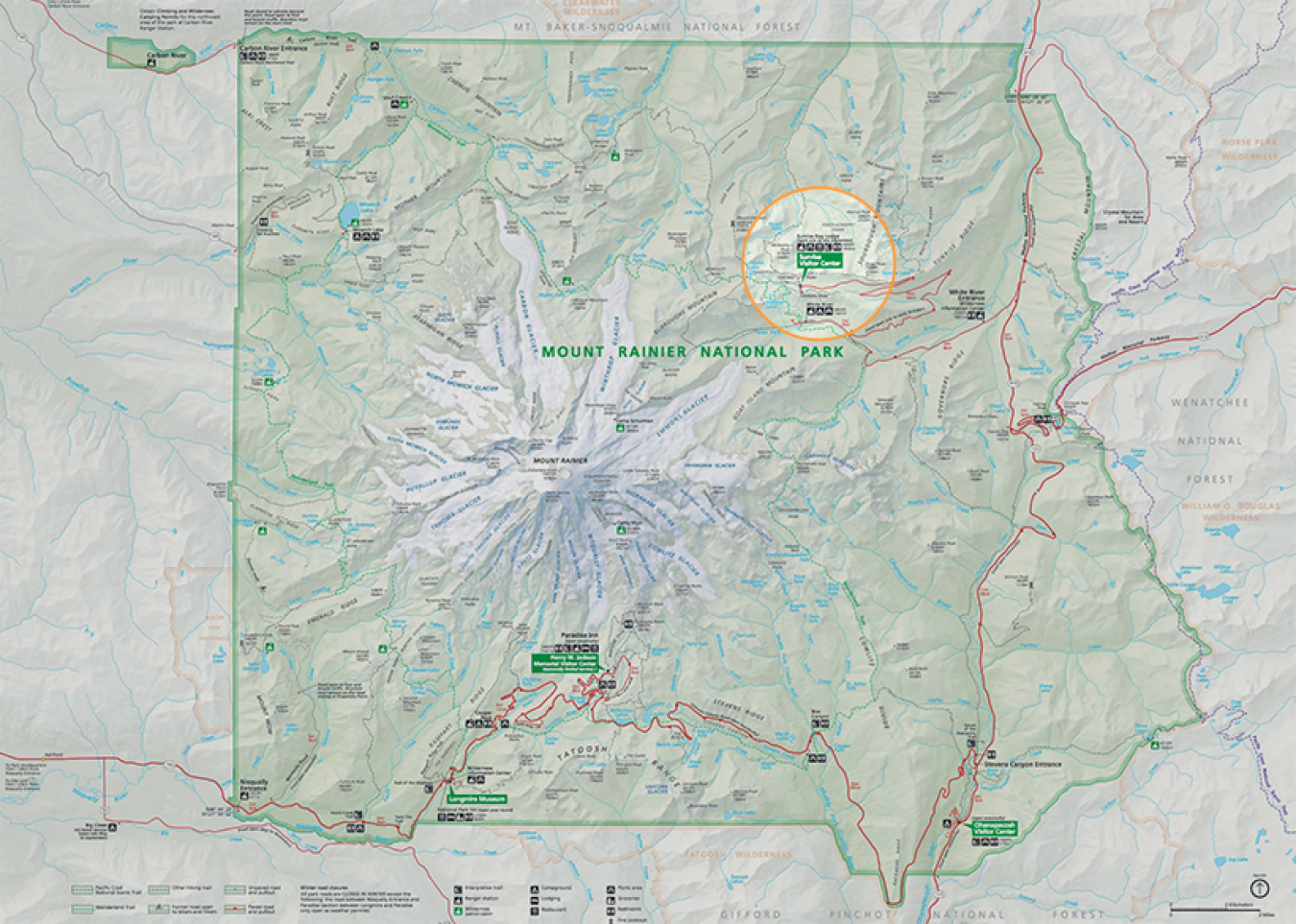

Mount Rainier National Park in Washington State encompasses 263,000 acres of wilderness. Sunrise, the highest location in the park that can be reached by vehicle, is a remote site that is open to visitors typically for four months per year from June through October. It is not served by an electric utility. The site is in an alpine zone located at 6,400 feet above sea level and receives abundant snowfall.

In 2005, the National Renewable Energy Laboratory (NREL) collaborated with Sunrise staff to complete an energy and financial analysis of converting the park facilities from diesel to renewable energy and implementing energy conservation measures.

Sunrise consists of several facilities, including the lodge, a comfort station, two apartment buildings, and a multi-use building containing a water plant, powerhouse, and fitness center.

The Sunrise Lodge is a two-story wood framed structure constructed in 1931 that serves as the visitor center and staff housing. It accounts for approximately 90% of the energy used at Sunrise.

Prior to the NREL collaboration, the lodge was powered by two diesel generators, one 113 kW generator installed in 1992 and one 90 kW generator installed in 1985. These generators were oversized for the site loads. Because of this, they were not operating efficiently and certain loads such as lighting needed to remain on 24/7 to maintain a minimum load on the generators.

Energy Efficiency

NREL estimated that energy conservation measures (ECMs) could reduce the average daily load across the whole site from 704 kWh/day to 136 kWh/day and the Sunrise Lodge building average daily load could be reduced from 307 kWh/day to an estimated 54 kWh/day.

NPS implemented many of these ECMs, including new refrigerators, washing machines, boilers, water heaters, and replacing electric stoves and dryers with propane models. In the lodge, a freezer was replaced at end of life and lighting was upgraded to LEDs.

The lodge still has potential for additional energy efficiency upgrades, which would reduce reliance on a propane generator and increase the proportion of power provided by solar.

Hybrid Photovoltaic System

NREL also provided recommendations for a hybrid photovoltaic (PV) system, using the Hybrid Optimization of Multiple Energy Resources (HOMER) Software to model and optimize the system. The original analysis predicted that Sunrise would get 76% of its annual energy from solar PV.

NREL also recommended the following specifications:

- Use at least a 30° tilt for the system to expedite snowmelt.

- Ensure that the lower edge of the panels are at least 10 feet above the ground to account for heavy snowfall.

- Bring panels up to the top edge of roof and seal them to prevent ice buildup behind panels.

- Pair this system with a propane generator.

- Install deep cycle batteries, enough for 2.5 days of storage.

Based on these recommendations, analyses, and specifications, NPS installed a PV hybrid system in 2017. This system included:

- 32.2 kW of roof-mounted solar PV on two roofs: 7.8 kW on the water tank house roof and 24.4 kW on the multi-use building. This consisted of 115 modules, 280-W each.

- 2 banks of 96 battery modules providing a total of 768 kWh of storage.

- A total of 30 kW 208 V, 3-phase inverters (two 10 kW inverters and two 5 kW inverters) for DC to AC conversion.

- An additional six 6 kW DC inverter/charge controllers to provide charge to and from batteries.

- A 45-kW 3-phase propane generator, running approximately 144 hours per year and using 570 gallons of propane, which replaced the existing diesel generators.

Extreme Snow Caused Damage to the PV System (2019–2021)

This site regularly experiences deep and dense snowfall. Wind-blown snow accumulates especially high on one side of the powerhouse building, often reaching above roof level. This gives additional snow nowhere to shed as it builds up atop the solar PV modules. An estimated 8 feet of snow has piled up atop the modules.

In the 2019–2020 winter, snow accumulation ultimately damaged some of the roof mounted solar PV panels on this building. The module on the bottom right of the array had cracked glass. Six adjacent modules along the bottom row had their metal frames pulled off by the heavy snow and ice. Park staff replaced the broken module and installed a wooden beam to support the frames on the lower row of modules in preparation for the following winter.

The following winter of 2020–2021 had heavier snowfall than the previous winter. In the area that was previously damaged, ten of the 84 panels on this roof (12% of the panels on this roof, 9% of panels at the site) suffered damage; three of these were crushed and had broken glass.

These ten modules were adjacent to each other in the lowest row of panels on the roof. It is likely these ten panels had higher snow accumulation on them than on the others.

This loading also forced the modules downward, pulling on the racking system. Some module frames on the bottom of the modules were pulled free of the modules.

As the modules were pulled down, it is possible that the previously installed wooden support bar levered upwards on the underside of the modules, contributing to the damage.

The site is closed and inaccessible for the winter, so this damage was discovered by site staff the following summer.

Spring 2021: Ten damaged and crushed panels in the bottom row, right side of the building (left). The weight of snow forced the modules downwards, deforming the racking and the previously installed wooden support (right).

Retrofit

Site staff were very motivated to repair and improve the system to avoid future damage in this challenging climate. Through the Department of Energy's Federal Energy Management Program (FEMP) technical assistance program, staff engaged experts at NREL and in the solar industry to determine a retrofit plan, which included a Sunrise site staff visit to NREL to discuss and review a retrofit design.

After this visit and iteration on the retrofit design, site staff replaced the ten damaged modules and implemented extra structural support measures to protect them under the weight of expected future heavy snow loads. This retrofit was completed in the summer of 2021.

One measure staff took was to add one additional rail under the modules (3 rails were used in the original installation). This allowed two extra mounting points per module, for eight total. These extra mounting points resist deflection of the module and glass, so it is less likely to suffer damage under heavy snow loads.

On top of these rails, under the backside of the modules, site staff installed support pads in direct contact with the backside of the module. These supports are approximately 18 inches in length and there are two supports per module, centered and evenly spaced. The supports are made of a hard rubber material similar to a garage door weather seal with additional materials for increased rigidity. The use of pressure-treated wood is likely not ideal but was deemed the best option for resourceful site staff working under time pressure to complete the retrofit before spring opening.

The damaged modules were replaced with 320-W modules. These modules have a published 6000 Pa front load rating using a six-point mounting system. The eight-point mounting with rear supports may enable the modules to withstand even more pressure. A 6000 Pa load equates to 2,241 lbs. of snow distributed evenly across the 18 ft2 panel, or about 10 feet of fresh snow.

Finally, to provide additional support to the lower frame of the modules, NPS staff installed an angled aluminum support against the lower side of these new modules, located beneath the modules to not catch the snow.

Success: No Snow Damage During Heavy Snow Season (2021–2022)

The 2021–2022 winter saw heavy snow at Mount Rainier, but the entire system, including the 10 replaced modules, survived with no damage and produced power when connected the following summer. The maximum snow depth at a nearby but 1,300 ft lower elevation National Oceanic and Atmospheric Administration's Global Historical Climatology Network station recorded a maximum snow depth of over 13 feet. Accumulations were most likely higher at the higher elevation Sunrise site.

Financial Savings and Environmental Benefits

Prior to the installation of the hybrid solar power system, the diesel generators ran 24/7 during the summer season when the park was open, consuming 13,080 gallons of fuel per season. The installation of the hybrid solar power system and implementation of energy efficiency measures resulted in a reduction in fuel consumption of 11,954 gallons, or 91%, saving an estimated 279,000 pounds (140 tons) of CO2 emissions over the four-month season.

91% reduction in fuel consumption and an estimated 140 tons of CO2 emissions saved over the four-month season

Savings from Retrofit

The replaced panels offset costs, fuel use, and emissions compared to what would have occurred if the system was not retrofitted.

The ten 320-W panels would produce around 1,699 kWh per season. This is equivalent to the power generated from burning about 322 gallons of propane (assuming 90,000 Btu/gallon of propane and generator efficiency of 20%), offsetting approximately 4,083 pounds (2.1 tons) of CO2 per year.

Should the retrofit measures enable the system to survive for 25 years, this equates to approximately 40,000 kWh produced, 7,585 gallons of avoided propane combustion, and 49 tons of avoided CO2 emissions. The 40,000 kWh would save an estimated $25,300 in present day dollars (assuming 0.5%/year PV production degradation, 4.92% propane rate escalation, 3% discount rate).

The costs of the retrofit were not provided by NPS, but amounted to materials costs of the replaced panels, wood, support bars, and hardware, estimated at around $4,000. This gives a net present value of just the 10 retrofit panels of around $21,300, with a simple payback period of 4.5 years.

Takeaways Applicable to Other Sites

For other federal sites experiencing issues, damage, or concerns about performance of PV systems, contact FEMP for technical assistance.

This case study provides a great example of a successful installation of a hybrid-PV system in an environmentally harsh location. The system is functioning and producing well, demonstrating a successful deployment of an off-grid renewable-hybrid system.

Overall, the system has survived the elements well. Even though there was some damage at this site, only 10 of the 111 panels installed in 2017 have been damaged and needed replacement. While this added cost to the original system, repairing and retrofitting with more robustness to survive the conditions is expected to save over $20,000 over 25 years compared to not repairing the system.

The main cause of the damage to the PV system was aluminum frames detaching from the PV modules. In recent years, PV module frames have been manufactured to thinner and shallower specifications. More research is needed to determine if thicker frame type and dimensions would be more likely to survive in regions that experience heavy snowfall.

More attachment points supporting the PV modules and support pads under the backside of the modules may help the modules avoid damage by limiting how much they flex under the weight of snow loads. Published module design load ratings increase with more support points.

Finally, dedicated, engaged, knowledgeable, and motivated site staff were crucial for the repair and improvement of the PV array at this site. This site also benefitted from cooperation with and input from NREL and the PV industry.