Energy I-Corps participants consider their work together.

Training for Energy I-Corps Cohort 3 was held July 12–Aug. 25, 2016, in Golden, Colorado, and Washington, D.C.

Cohort 3 was composed of eight teams from Argonne National Laboratory (ANL), Fermi National Accelerator Laboratory (FNAL), Idaho National Laboratory (INL), Lawrence Livermore National Laboratory (LLNL), National Renewable Energy Laboratory (NREL), Oak Ridge National Laboratory (ORNL), and Sandia National Laboratory (SNL).

See photos of Energy I-Corps Cohort 3 on our Flickr stream.

Teams and Technologies

Team Members

- Principal Investigator: Jake Gentle

- Entrepreneurial Lead: Donna Rennemo

- Industry Mentor: Dale Douglass

Technology Description

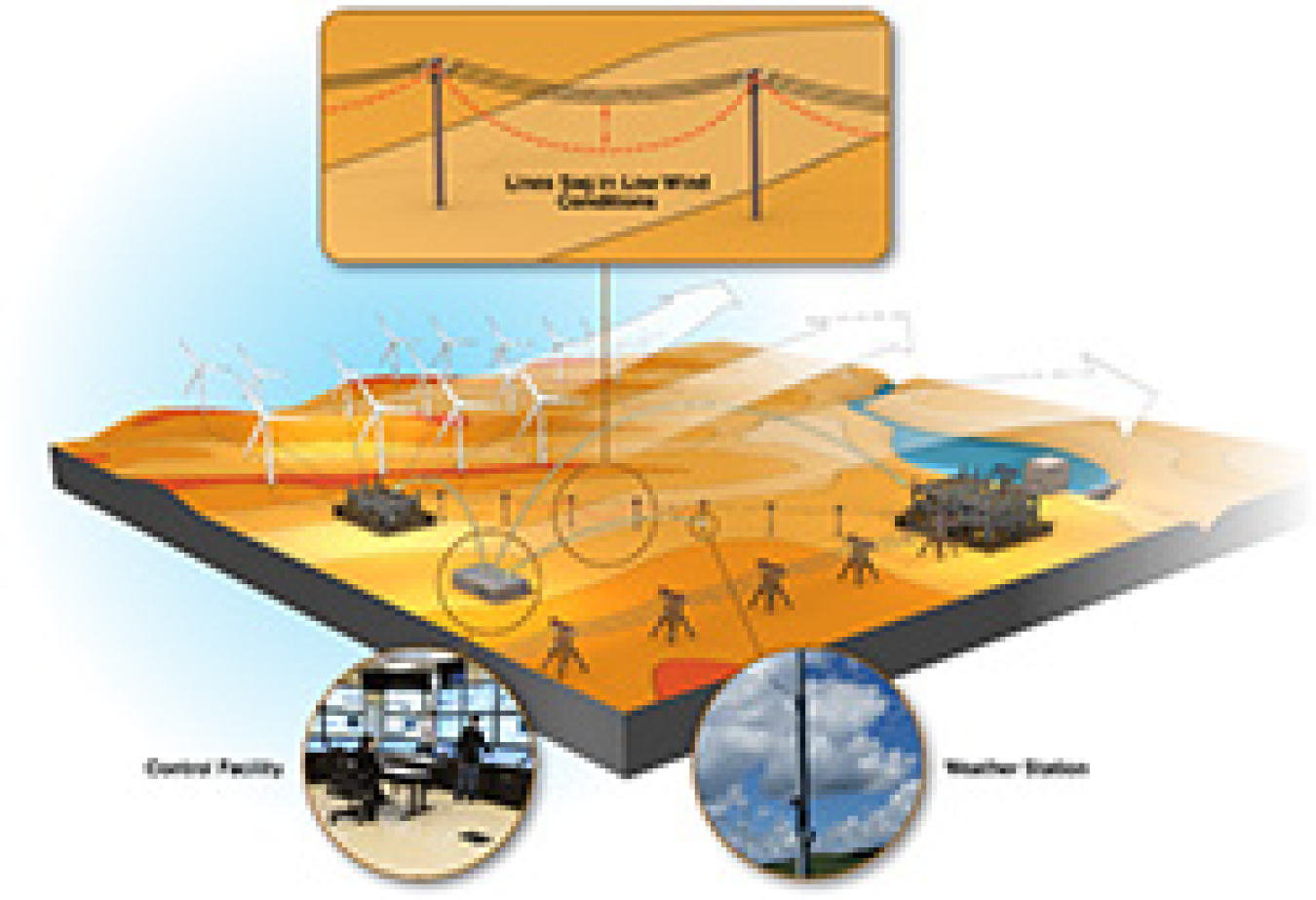

The General Line Ampacity State Solver (GLASS) software is a crucial piece of INL’s Dynamic Line Rating (DLR) methodology, a solution that is designed to provide industry with a solution to current transmission-line congestion. Glass enables transmission operators to utilize an extra 10% to 40% capacity above their current limits, enabling critical infrastructure to be better utilized. Especially in times of extreme power demand such as instances caused by bomb cyclones or 2012 damages caused by Super Storm Sandy, DLR can provide the much-needed transmission capacity to provide power to load generators in extreme need.

GLASS is state-of-the-art as measured by cost, accuracy, and dependability and will better allow human operators and system planners to make informed decisions and take appropriate actions. Ultimately, GLASS will mitigate transmission line congestion to better integrate wind power, improve the grid as a whole, and reduce costs by optimizing current infrastructure and minimizing the need for new transmission lines.

In order to establish limits on the amount of electrical current one transmission line can carry without overheating, grid operators have traditionally relied on Static Line Ratings, which are based on a fixed set of conservative environmental conditions. Power transfer capacity is affected by three main elements: stability, voltage limits and thermal ratings. Optimizing and better managing this power transfer capacity in real time is a primary goal of making the transmission grid "smarter." Of the three ratings affecting power transfer capacity, thermal ratings represent the greatest opportunity to improve upon past practice and quickly utilize the grid’s full ability, and this is where INL researchers have turned their focus.

Widespread adoption of DLR practices will be an important step towards achieving the nation’s renewable energy goals. DLR will enable renewable energy systems to come online more quickly by making better use of existing grid infrastructure. DLR informs system planners and grid operators of available transmission capacity to help alleviate grid congestion.

Team Members

- Principal Investigator: Jayakar Charles Tobin Thangaraj

- Entrepreneurial Lead: Daniel Bowring

- Industry Mentor: Richard Penning

Technology Description

FNAL has developed a unique design for a compact SRF high-average power electron accelerator for industrial applications. Small and light enough to mount on mobile, skid-mounted platforms, the FNAL's accelerator is capable of 5-50 kW average power and continuous wave operation thus enabling array of more energy-efficient manufacturing solutions.

Team Members

- Principal Investigator: Xing Chen

- Entrepreneurial Lead: Luxi Li and Yan Zhang

- Industry Mentor: Ray Stachowiak

Technology Description

Fibrous structured materials range in scale and is critical in many applications. It is important to be able to measure fiber morphology such as size, orientation, and other features fast, accurately, and reliably. Unable to find a satisfactory existing solution, we developed a novel image analysis algorithm and prototype software, which offers significant improvements over existing methods. It has potential to significantly increase productivity in a broad range of industrial and research applications.

Team Members

- Principal Investigator: Mihail Bora

- Entrepreneurial Leads: Brian Beekley, Lewis Wogan

- Industry Mentor: Eric Cummings

Technology Description

Our team aims to improve design and reliability of photovoltaic products resulting in increased service lifetime, decreased failure rates, and consequently lower financing rates for solar installations. The technology measures water content in polymeric encapsulant materials used in photovoltaic modules at concentrations lower than 0.1% by weight. This enables direct measurements on field-deployed modules for comparison with accelerated-tested products.

Team Members

- Principal Investigator: Kaushik Biswas

- Entrepreneurial Lead: Mini Malhotra

- Industry Mentors: Diana Fisler, Johns Manville

Technology Description

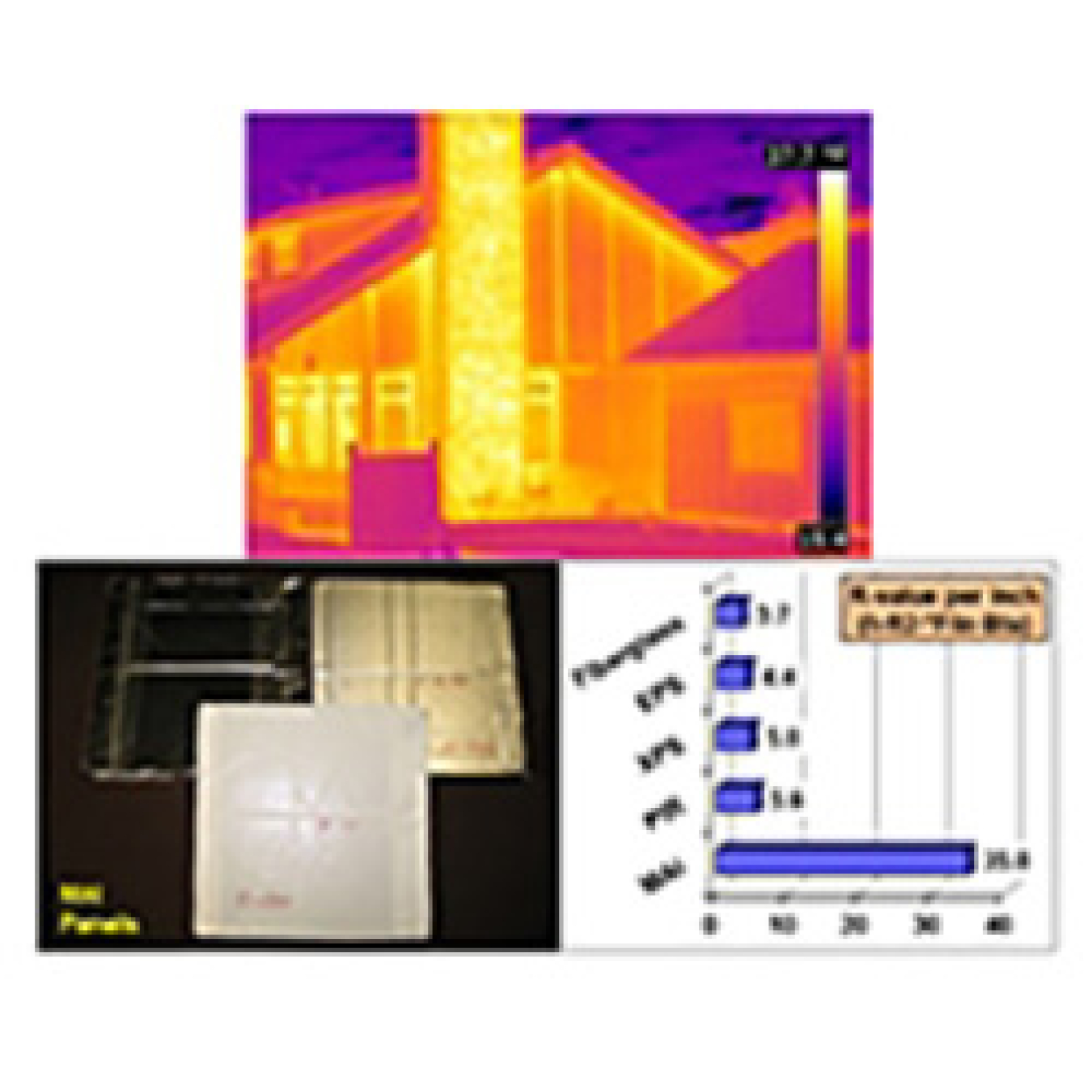

Lower-cost, high-performance insulation systems are a high-priority research area for the U.S. Department of Energy's Building Technologies Office. VIPs offer a step change in performance (R40/inch) versus state-of-the-art insulation materials (R6/inch) but at a high cost. A new product, modified atmosphere insulation (MAI), eliminates most of the VIP production steps and is 50% less costly. The thermal performance of MAI is the same as VIPs, and work is ongoing to stimulate adoption of MAI in building applications.

Team Members

- Principal Investigator: Matthew Carlson

- Entrepreneurial Lead: Yasmin Dennig

- Industry Mentor: Bill Hartmann

Technology Description

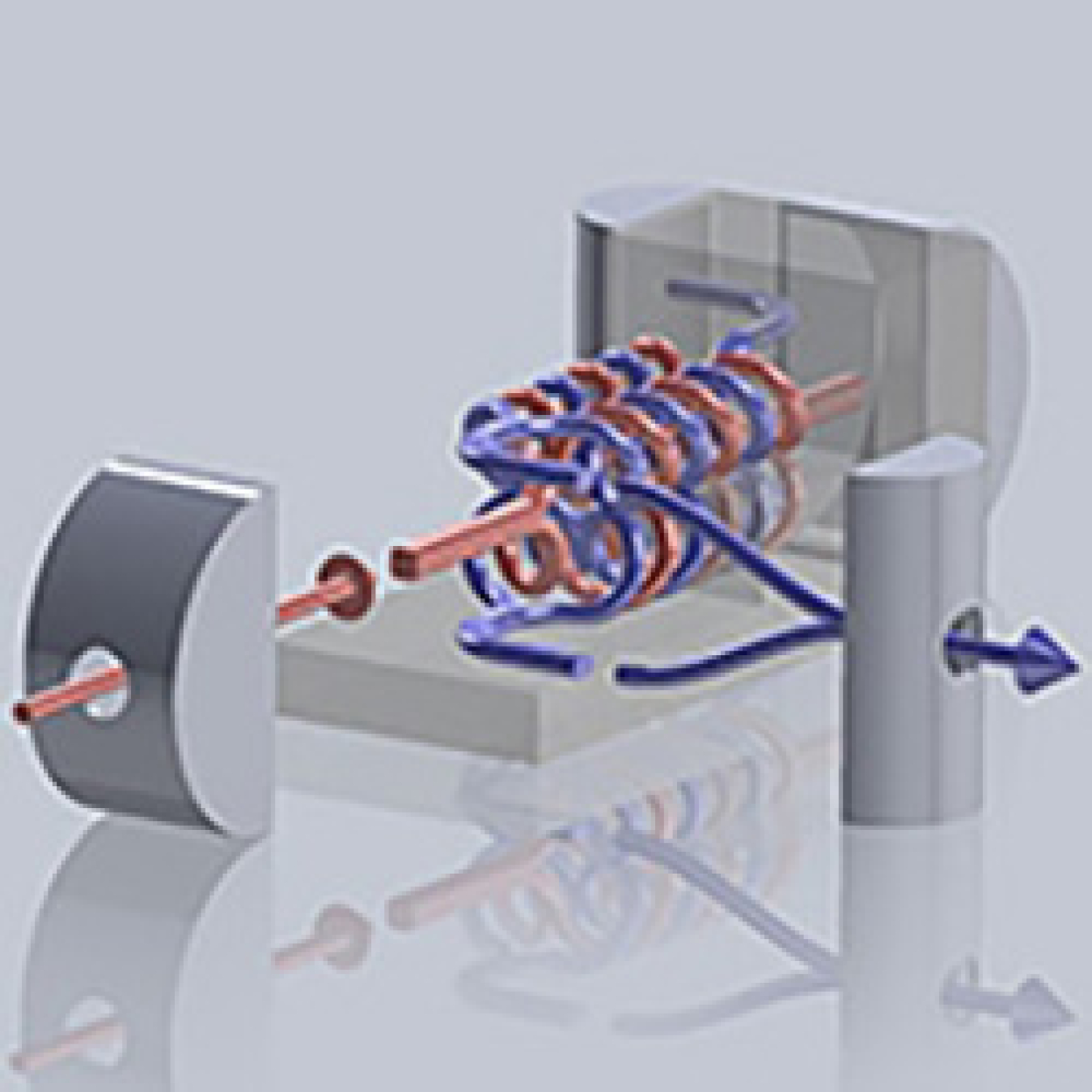

SNL's monolithic technology could significantly reduce the cost, size, and manufacturing lead time of compact heat exchangers for a variety of applications while simultaneously improving their performance, material options, and channel design possibilities. While originally developed for nuclear power conversion cycle applications, monolithic technology could be deployed in the $12-billion, near-term industrial market as an independent pathway to commercialization.

Team Members

- Principal Investigator: Lance Wheeler

- Entrepreneurial Lead: Robert Tenent

- Industry Mentor: Robert Clarke

Technology Description

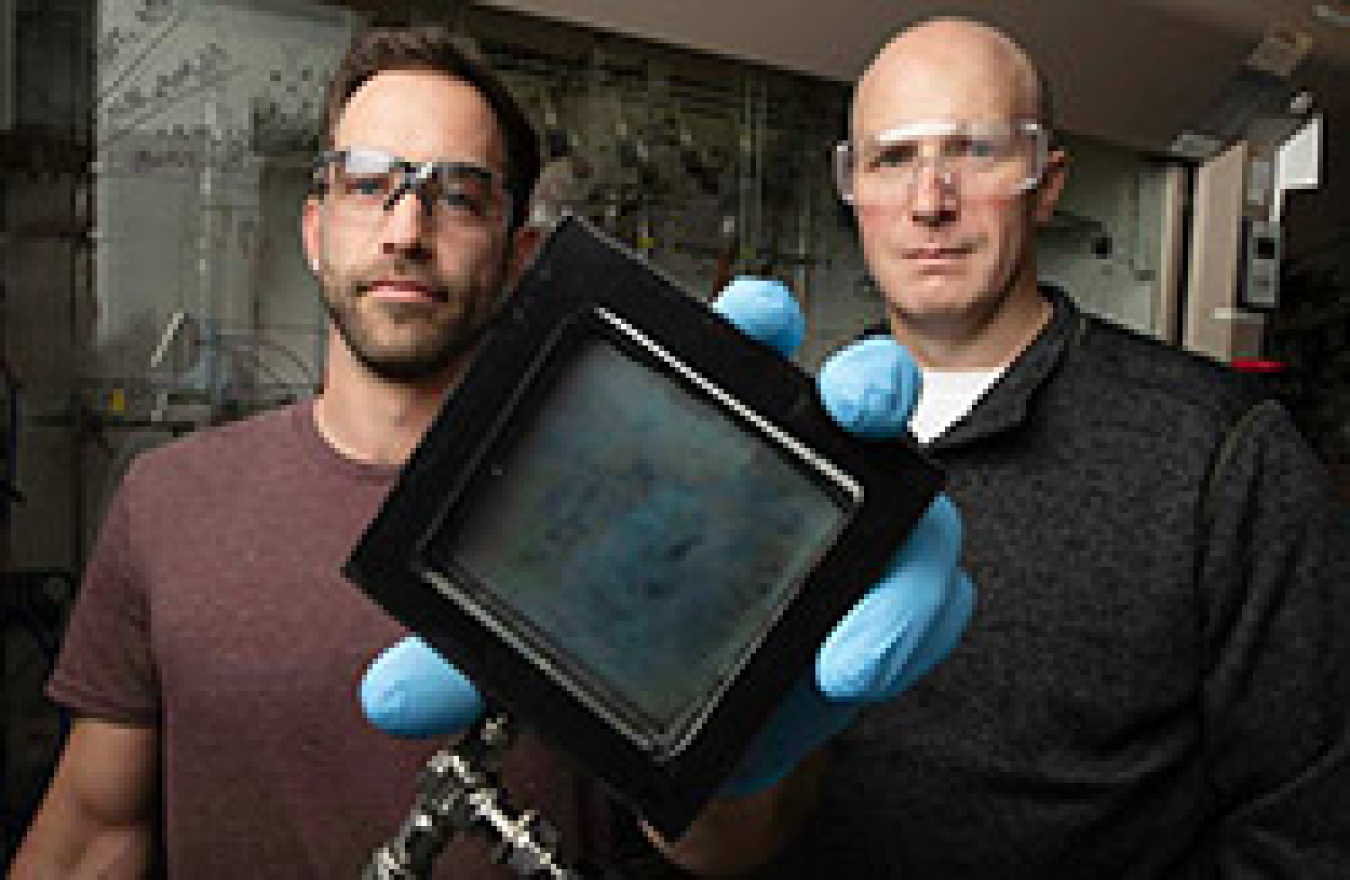

Our technology is the first demonstration of dynamic photovoltaic glass. The product is a highly transparent coating that responds to solar illumination by tinting to "switch" the coating into a photovoltaic device that efficiently harvests the sun's energy and simultaneously provides glare control for enhanced building efficiency and occupant comfort. The technology will revolutionize buildings by transforming them from significant energy sinks into a source of clean renewable energy.

Team Members

- Principal Investigator: Seth Snyder

- Entrepreneurial Lead: Jessica Linville

- Industrial Mentor: Erik Pedersen

Technology Description

We design digesters and additives to enhance anaerobic digestion (AD) to process food wastes. AD is a natural process that uses bacteria to convert organic wastes into biogas, a mix of CH4 and CO2. AD is used to reduce waste volumes. Our additive technology increases digestion rates and the energy content of the biogas. Our design format enables the system to fit into modular units and maximize performance. ANL patented the additive technology, and Linville is patenting the digester design.