Pacific Northwest National Laboratory instructors were looking for some fresh ideas to make their Operational Technology Assurance course, sponsored by NNSA, more realistic for attendees.

National Nuclear Security Administration

January 12, 2024

Pacific Northwest National Laboratory (PNNL) instructors were looking for some fresh ideas to make their Operational Technology Assurance (OTA) course, sponsored by NNSA, more realistic for attendees. Fortunately, through a partnership with Washington State University (WSU), engineering students delivered an imaginative and cost-effective solution.

Developed and delivered by PNNL, the OTA course teaches tools, techniques, and practices that reduce the risk of cyber compromise to operational technology within the Nuclear Security Enterprise. The course has been in high demand and was offered seven times in 2023, with more than 140 assurance practitioners within the nuclear weapons complex completing it.

NNSA challenged OTA instructors – PNNL’s cybersecurity researcher Christian Perry, nuclear engineer Ben Kowash, and materials scientist David Koch – to provide additional hands-on experiences to mimic assessments and make course content more relevant to attendees. Perry, Kowash, and Koch looked for a way to integrate multiple generations of technology that participants use every day into one immersive training. With that goal in mind, they turned to WSU’s Industrial Design Clinic to design, fabricate, and deliver a realistic mock system – a vintage-style glovebox.

The Industrial Design Clinic pairs student teams and industry partners to design and develop prototypes that meet specific needs – such as calibration equipment for vehicle anti-lock brakes or upgrades to food processing equipment. Over the course of a semester, students work to research the problem, design solutions, and work with the WSU fabrication shop to build the prototype equipment. PNNL has worked with WSU Industrial Design Clinic students for more than 10 years, addressing many research equipment needs on projects sponsored by NNSA.

Reflecting on the completed vintage-style glove box, WSU mechanical engineering student Travis Luther said, “We definitely had a learning curve with project management. We realized early on we needed to split up the tasks.”

“When the industry partners work closely with the student teams as PNNL did, the students are successful,” said Industrial Design Clinic Professor Emily Larsen.

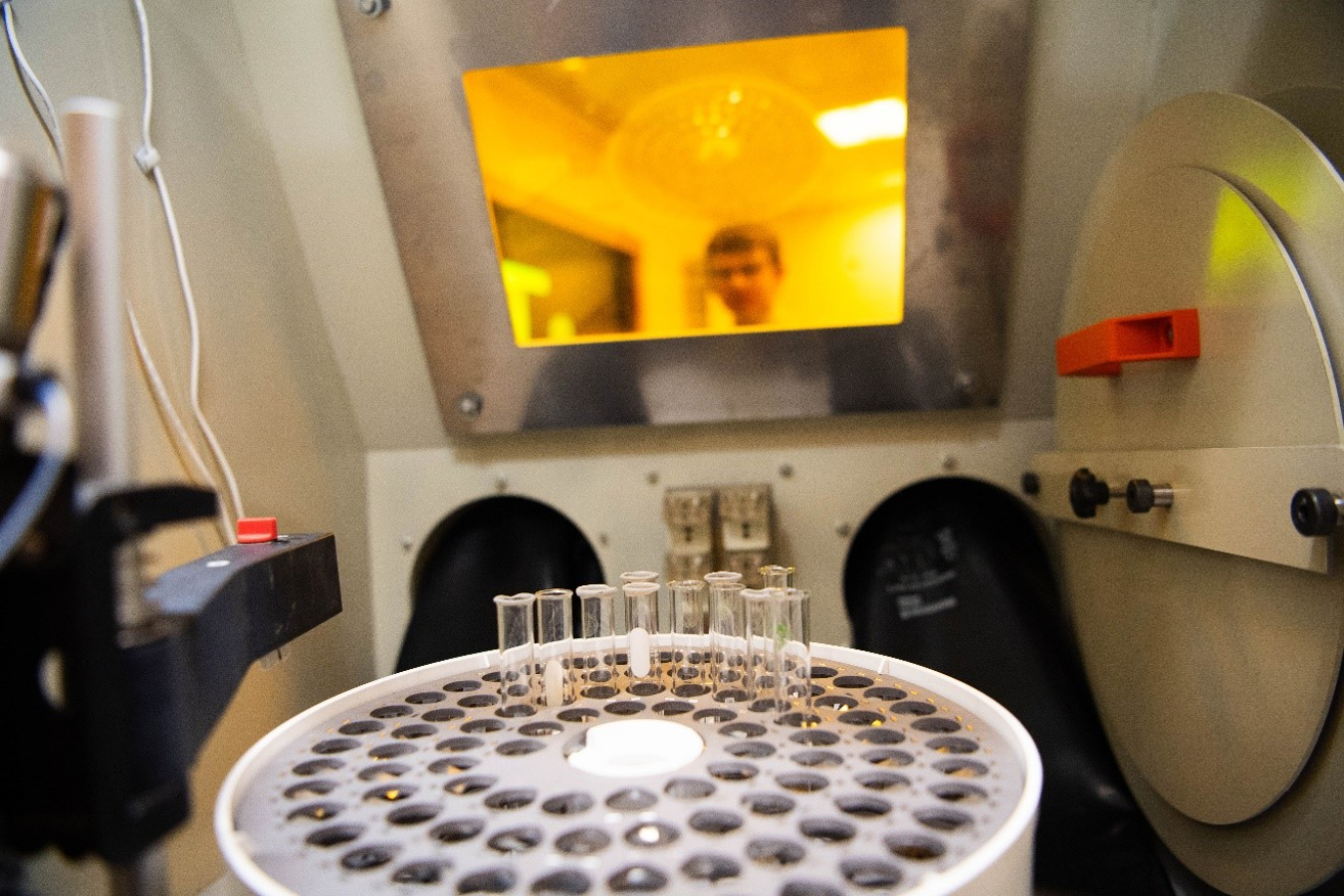

In December, the WSU team delivered the project for the OTA course, a glove box with a sample transfer port and two glove ports and several mock testing systems within. Now in PNNL hands, the system will be wired and rendered operational to support the course curriculum.

The WSU team included Sarah Carlson, Timothy Lara, Travis Luther, and Solon Simpson. To help them present the project to the PNNL, Simpson played the part of a fictional scientist, with a nostalgic cinematic vibe.

“The students delivered an amazing project under budget. When we partner with the Industrial Design Clinic, the students bring their fresh perspectives to our engineering challenges. Collaboration allows each of us to do what we do best,” said Koch, a mentor for the WSU team.