The DOE/NNSA Mobile Packaging Program has evolved over time as a result of lessons learned from exercises and real-world missions to recover nuclear material.

National Nuclear Security Administration

November 16, 2022

The U.S. Department of Energy and NNSA play a critical role in the Nation’s ability to prevent, counter, and respond to nuclear threats. As part of its mission, they maintain the capability to rapidly deploy technical experts and specialized equipment anywhere in the world on short notice to safely characterize, stabilize, package, and remove nuclear materials.

The most challenging aspect of creating an improvised nuclear device is acquiring a sufficient quantity of weapons-usable nuclear material. Accordingly, countries with these materials go to great lengths to secure and safeguard them against falling into the wrong hands. However, should highly enriched uranium or plutonium be identified in a less-than-secure state, or if a partner nation requires assistance in packaging and removing these materials on short notice, DOE/NNSA stands ready to respond.

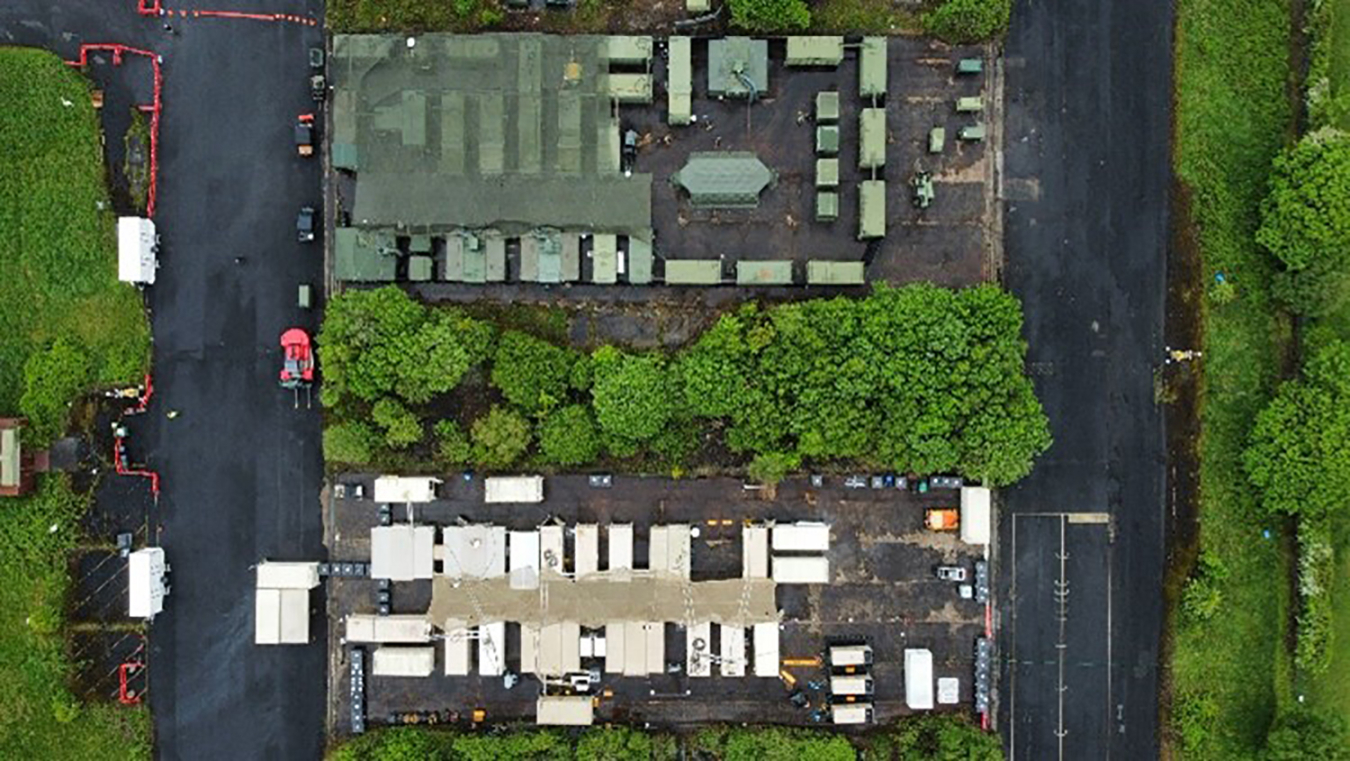

The Mobile Packaging Program provides a globally unique capability to rapidly deploy two teams and corresponding facilities designed with a flexible and scalable footprint, allowing their configuration to be tailored for specific missions. The Mobile Uranium Facility (MUF), located at Oak Ridge National Laboratory, employs specialized teams from ORNL and the Y-12 National Security Complex, while the Mobile Plutonium Facility (MPF) is located at, and led by, technical specialists from the Savannah River National Laboratory.

These capabilities have evolved over time as a result of lessons learned from exercises and real-world missions to recover nuclear material.

These capabilities have evolved over time as a result of lessons learned from exercises and real-world missions to recover nuclear material.

The first such learning moment was in 1994, when the U.S. Government conducted a sensitive mission involving the removal of at-risk, highly enriched uranium located in Kazakhstan. Once packaged by the technical experts from ORNL and Y-12, the material was shipped to the United States for storage and disposition. Project Sapphire, as it was named, was the origin of the mobile packaging program and the growing realization for the need of an institutionalized, deployable capability. In 1998, DOE was again called upon to recover material on short notice. Project Olympus involved DOE experts traveling to Georgia to package and retrieve fresh and spent fuel, further underscoring the need to be prepared to conduct these types of missions in the future.

In 2004 during the early stage of the Iraq War DOE/NNSA was called upon again, this time to remove 750 kg of enriched uranium and 6,000 curies of high-activity sources. A group of DOE/NNSA experts quickly assembled the necessary equipment, deployed to Iraq, and packaged material over the course of 50 days. The team successfully accomplished their mission, navigating the simultaneous challenges of war and an austere environment. This operation – called Project Maximus –was the third real-world application of the evolving mobile packaging capability. It highlighted the importance of flexibility in the facility’s design and the need to be prepared to receive and process a wide variety of different materials.

In 2007 and 2008 the team found themselves once again in Iraq for Operation McCall as the government requested technical assistance to facilitate the packaging and removal of yellowcake along with more high-activity sources. As with Maximus, McCall made clear that the teams must be prepared to address a broad range of vulnerable materials. While McCall did not involve handling enriched uranium, it involved much more material than any previous mission and significant logistical challenges.

Using the lessons learned from Project Sapphire, Project Olympus, Project Maximus, Operation McCall, and other activities, the DOE/NNSA team has continuously refined what a deployable capability looks like, as these types of recovery and packaging scenarios will likely occur in the future.

Moving from a capability to actual facilities, today’s MUF and MPF include flexible and sophisticated analytic and packaging capabilities housed in an adaptable, deployable set of modular containers. Through regular deployments and exercises under real-world conditions, DOE/NNSA and its partners continue to adapt and improve their capabilities, ensuring DOE/NNSA is ready to respond on short notice to recover weapons-usable nuclear material anywhere in the world.

NNSA partnered with the Defense Threat Reduction Agency and the United Kingdom’s Ministry of Defence to exercise two rapid response capabilities critical to national security: the Mobile Uranium and Mobile Plutonium Facilities.

The Mobile Packaging Program teams must be prepared to adapt to whatever they encounter wherever they go. So the program conducts regular training exercises.