Data from spent nuclear fuel rods will be crucial to the development and licensing of new fuel technologies.

February 29, 2024

Idaho National Laboratory recently received a shipment that took more than a decade to deliver.

After years of complex negotiations with the state, and dozens of deliverables achieved by the U.S. government to manage the lab’s radioactive legacy waste, INL finally has access to 25 irradiated experimental fuel rods.

That may not seem like a lot, but it is more than enough to start with.

The data we get from these fuel rods will be crucial to the development and licensing of new fuel technologies that are designed to enhance safety performance and operate for longer stretches of time in a reactor—ultimately saving customers more money on their energy bills.

The receipt of these rods also sends a clear message to the world that Idaho and INL are back open for business with a suite of testing capabilities that simply can’t be found anywhere else.

Building world-class R&D infrastructure

Restrictions on irradiated fuel transfers into Idaho started in 1995 when DOE, the state of Idaho, and U.S. Navy agreed to certain requirements to help clean up and dispose of the nation’s legacy waste at the lab.

Since INL couldn’t receive commercial spent fuel shipments during this time, DOE conducted alternative research projects outside of the state at other labs and international partners to help fill the void.

But DOE and INL did move forward with plans to invest heavily in research and development infrastructure as an appetite for current and new reactor technologies started to grow.

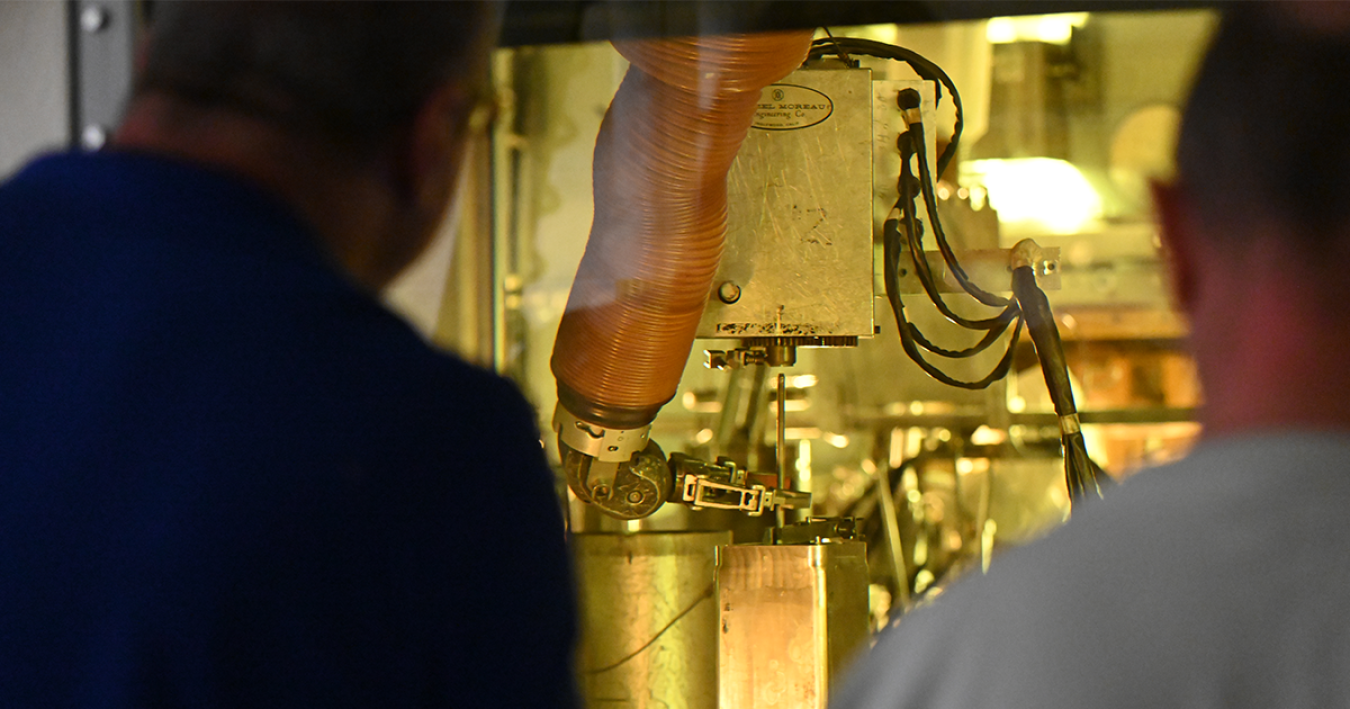

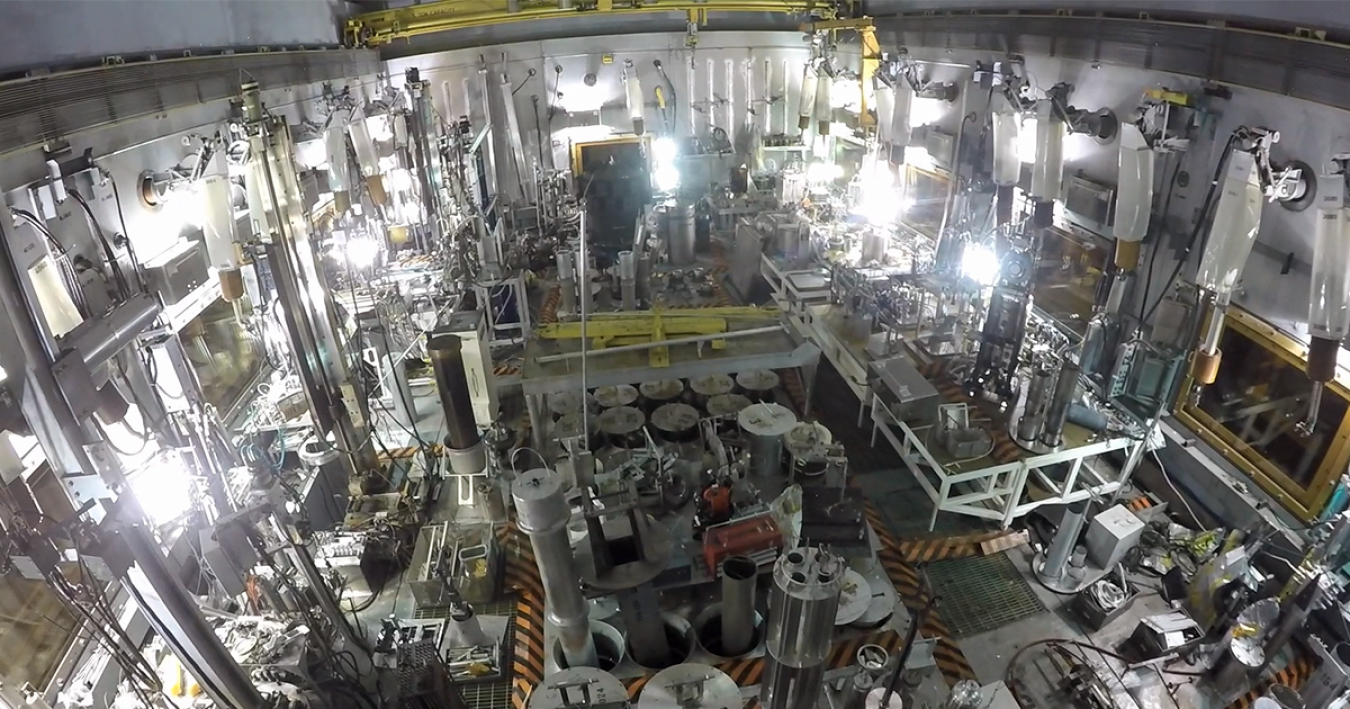

These investments led to new testing capabilities at our Advanced Test Reactor that will help mimic the years of wear and tear that these fuels would be subjected to in a commercial reactor.

We also restored transient testing at our TREAT facility to help determine the safety limits of the fuel and expanded our post irradiation handling and testing capabilities at our Materials and Fuels Complex to better understand fuel performance.

To put it simply, we continued to develop some of the best R&D resources in the world to support the nuclear fuel cycle.

All we needed now was the fuel.

Thanks to the incredible collaboration and hard work of our Environmental Management Office, INL, and the state of Idaho—a key requirement was met last year with the start-up of the Integrated Waste Treatment Unit.

This first-of-kind facility was built to treat nearly 900,000 gallons of sodium bearing waste at the INL site.

It also opened the door for INL to receive this special shipment.

What’s inside the box?

The 25 fuel rods shipped to INL were all developed and manufactured by Westinghouse with technical assistance from several of our national labs.

Some of the fuel rods were developed with advanced materials to help extend the time they can operate in a reactor and increase its power output.

Researchers believe once they are licensed for commercial use, the fuel could stretch its clean power generation from 18- to 24-month cycles.

The results would lead to fewer refueling outages and less spent fuel that would require permanent disposal.

Some of the cladding and fuel materials were developed with the support from our Accident Tolerant Fuel program to help industry enhance the safety of fuels by allowing for longer response times at high temperatures in postulated accident situations.

They’re also expected to boost the performance of our commercial fleet of reactors and could be commercialized before the end of the decade.

Finally, some of the rods will be used for a joint study with an international partner to explore technical, economic, and nonproliferation considerations associated with the electrochemical recycling process and other spent fuel management options.

It’s important to note that the U.S. does not commercially recycle fuel for use in its reactors, but this work will help to inform the Department’s understanding of these issues.

Now comes the important part

We’ve been patiently waiting nearly two decades for a shipment like this, and our researchers are eager to roll up their sleeves and get to work using some of the best facilities in the world.

The data drawn from this fuel will be pivotal to the future success of the nuclear industry, which currently generates nearly 50 percent of our clean power.

We simply can’t get to net-zero emissions without nuclear energy and the work being done today at INL will have a lasting impact on our clean energy future of tomorrow.

This work wouldn’t be possible without the continued collaboration between the federal government and the state of Idaho, and we are committed to fulfilling our promise to manage legacy waste safely and effectively at the site.

Interest in nuclear energy has never been higher, and it’s exciting to see the state of Idaho and INL help lead that charge.

Future updates will report the results of this important work.

Dr. Jon Carmack

Dr. Jon Carmack is the Deputy Assistant Secretary for Nuclear Fuel Cycle. Prior to this, he served as a senior technical advisor to NE from March 2018 to March 2023. He previously served as national technical director for NE's Advanced Fuels Campaign.

Jon began his career as a student at Idaho National Laboratory (INL) in 1989 and joined the Fuels and Materials Department after graduating with a B.S. and M.S. in nuclear engineering from the University of Washington in 1991. During graduate school he worked for Haliburton (NUS) Nuclear Utility Services. He left INL in 1999 and spent five years at BWX Technologies in Lynchburg, Virginia, returning to INL in 2004 to join the DOE Advanced Fuel Cycle Initiative program. He obtained his Ph.D. from the Department of Nuclear Engineering, University of Idaho, in 2012, focusing on fuel-cladding chemical interaction formation in fast reactor metallic fuels.

Jon is well-known as an avid skier, biker, farmer, and Toyota Land Cruiser aficionado.