High-temperature gas reactors can efficiently produce heat for electricity and industrial applications.

October 29, 2024High-temperature gas reactors use helium gas and ceramic materials to stabilize the fission process inside the reactor core.

They run on ceramic-coated fuel particles and are designed to efficiently produce heat (~750° Celsius) for electricity generation or to drive energy-intensive manufacturing processes, such as hydrogen production.

Several test, demonstration, and commercial high-temperature gas reactors were previously built in England, Germany, the United States, Japan, and China starting in the 1960s.

New designs are currently under development in eight countries, including the U.S., and some reactors could be deployed within the decade to meet the nation’s growing demand for clean firm power.

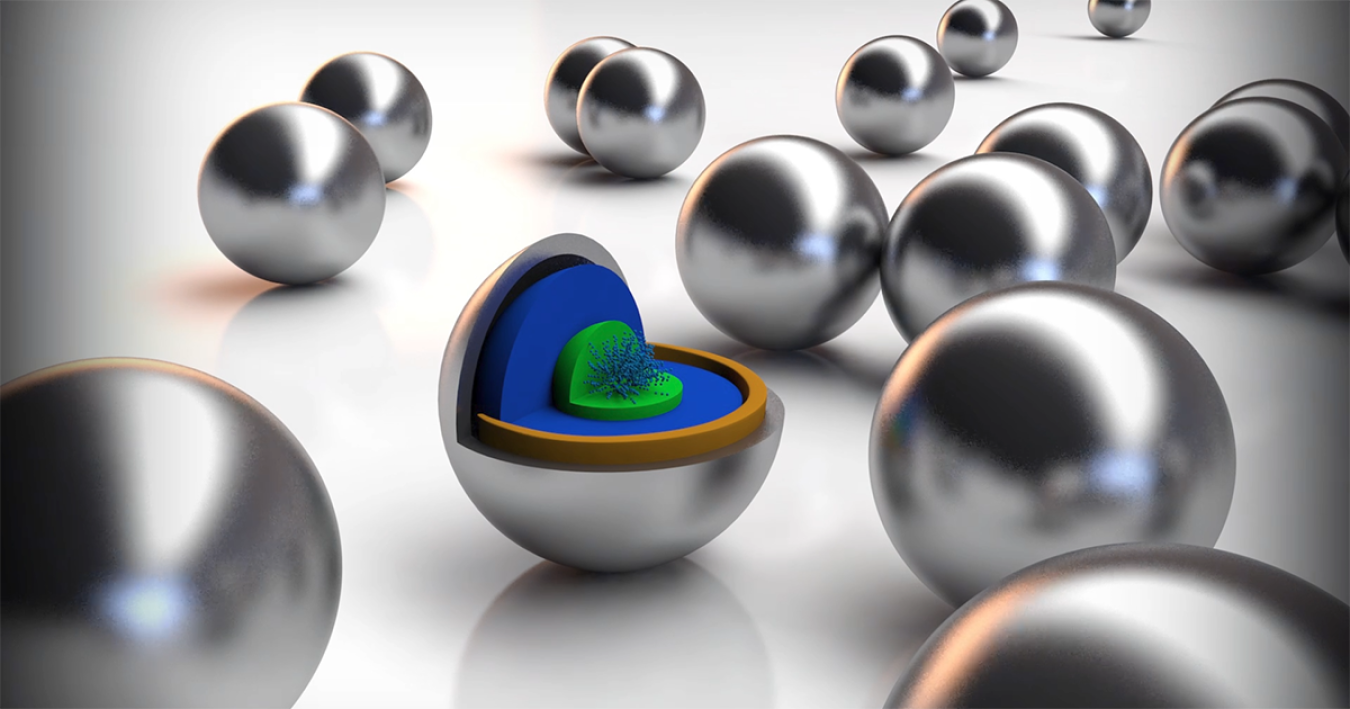

Robust TRISO Fuel Design

High-temperature gas reactors use robust TRi-structural ISOtropic particles, commonly referred to as TRISO fuel.

Each fuel particle is about the size of a poppy seed that can be placed into cylindrical fuel pellets or billiard ball-sized spheres called “pebbles,” depending on the type of reactor.

These layers act like individualized containment domes to largely retain radioactive fission products.

Their ceramic fuel form also means that TRISO particles can’t melt in a high-temperature reactor under any design-basis condition

Types of High Temperature Gas Reactors

High-temperature gas reactors are a relatively mature technology among other advanced reactor types based on its operational experience across the world.

The reactors come in two different core designs — prismatic and pebble bed.

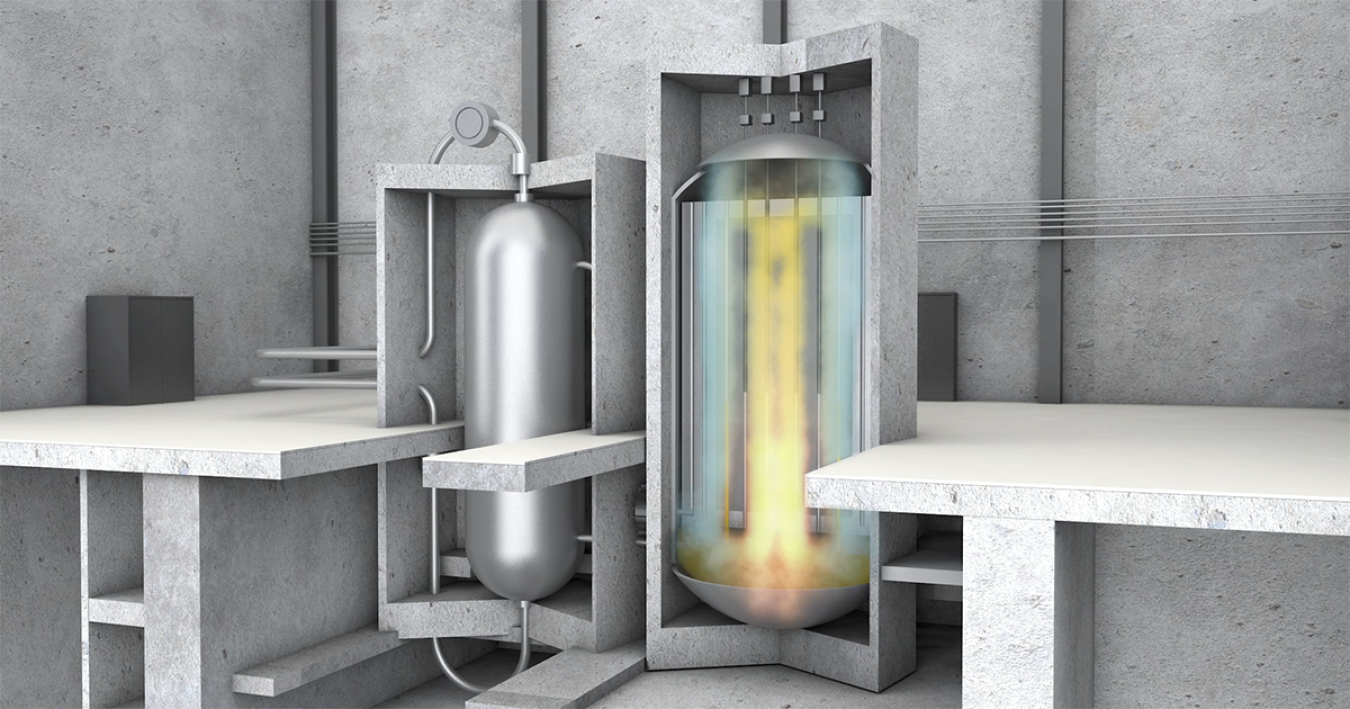

Prismatic Gas Reactors use graphite hexagonal blocks to form the reactor core structure and slow down the neutrons produced by fission to sustain the chain reaction. Each block contains channels for directing helium gas flow and holding stacks of TRISO fuel pellets, known as compacts.

Fission heats the helium that is being circulated through the core to a secondary system that heats water to create steam. The steam then turns an electric generator to produce emissions-free electricity.

The gas then returns to the reactor to be reheated in a closed loop cycle.

Pebble Bed Gas Reactors are essentially big “nuclear gumball machines.” The pebble bed core is filled with TRISO fuel pebbles that are surrounded by graphite reflector blocks. Helium is blown down through the pebble bed to extract the heat into a steam generator that produces electricity.

The reactor is continuously refueled by adding fresh pebbles into the top of the core as older ones are discharged from the bottom. The discharged pebbles are evaluated to determine whether they will be reinserted into the reactor or placed directly into on-site storage.

Enhanced Safety

High-temperature gas reactors offer several advanced safety features.

Their TRISO fuel particles are capable of retaining radioactive fission products in temperatures as hot as molten lava and are structurally resistant to neutron irradiation, corrosion, and high temperatures.

The helium gas used to cool the reactor is chemically inert and doesn’t react with the materials used in the reactor or with the fission process.

Finally, the graphite reflectors have excellent heat transfer properties that enable the core to cool down to a stable and safe end-state without any operator action.

Applications for High-Temperature Gas Reactors

High-temperature gas reactors are extremely versatile and offer several benefits.

Scalable and Modular Power Levels – A single high-temperature gas unit can deliver as little as 1 megawatt-thermal or up to 625 MWt depending on the application. Multiple units can also be built on one site to form a larger facility of up to 3,000 MWt.

Efficient Power – High operating temperatures enable emissions-free electricity with greater thermal efficiency compared to traditional light-water reactors.

Process Heat – High-temperature gas reactors can be located near facilities to drive industrial processes that require high quality steam or heat inputs, ranging from petrochemical and fertilizer production to oil refining to clean hydrogen production.

Online Refueling – Pebble bed designs can be continuously refueled to maximize availability for data centers and energy-intensive manufacturing processes.

The U.S. Department of Energy supports the development of high-temperature gas reactors and TRISO fuels through its Advanced Reactor Technologies and Advanced Fuel Campaign programs in coordination with university and industry partners.