National lab develops a radiation-resistant material that efficiently captures radioactive gases.

October 1, 2020

Pacific Northwest National Lab (PNNL) developed a radiation-resistant material that efficiently captures radioactive gases that are released during the recycling of spent nuclear fuel.

The new material greatly simplifies the recycling process, reduces the volume of nuclear waste that needs to be stored, and adds further economic incentives.

The trapped gases can be reused for a variety of products ranging from medical devices to commercial lighting.

Capturing without Cooling

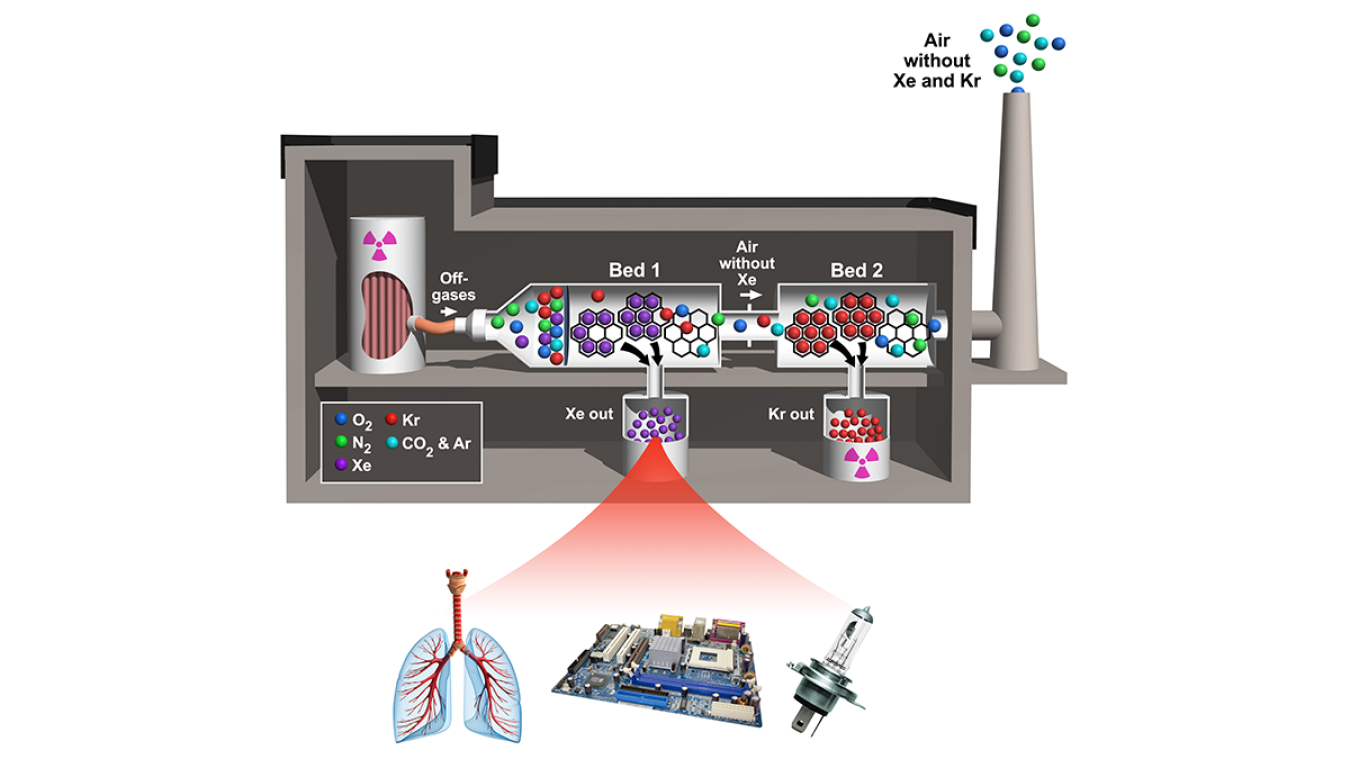

Current methods use cryogenic distillation—an expensive process that requires large equipment, cold temperatures and complex engineering to separate and sequester radioactive gases during the recycling of spent nuclear fuel. PNNL completely simplified this process by developing a radiation-resistant metal organic framework material (MOF) that specifically targets and traps xenon and krypton gases at room temperature.

MOFs are specific combinations of metal and organic materials that can be catered to capture certain gases in their sponge-like structures based on their molecular size. The new material, called SIFSIX-3-Cu, uses a copper-containing crystal that is stable in radioactive environments. The MOF is a tailored version of a material developed by an international collaboration back in 2016. The original material essentially eliminates the need for cryogenics and is expected to cut separation gas costs in half by drastically reducing the size and complexity of the separation process.

The new radiation-resistant material, which was highlighted in a recent study by PNNL, Massachusetts Institute of Technology, National Energy Technology Laboratory, University of Pittsburgh, and the University of South Florida, can be used in a new, simplified two-step process that first captures xenon gas before picking up smaller krypton molecules that pass through.

“Separating non-radioactive xenon provides an economic incentive further separating radioactive krypton in pure form reduces the volume of nuclear waste,” says PNNL material scientist Praveen K. Thallapally.

Industry Benefits

The captured gases recovered from spent nuclear fuel has a host of economic benefits spanning across a range of industries. Xenon is utilized in medicine as anesthesia, in space applications as a propellant in propulsion engines, and lighting from automobiles to camping headlamps. The capturing of krypton could also potentially benefit the nuclear industry by reducing the amount of spent nuclear fuel storage.

While the technology shows promise, researchers are examining the novel material’s stability under higher levels of radiation doses. The successful deployment of this technique could significantly improve the nuclear fuel cycle.

Further testing is being supported by DOE’s Gateway for Accelerated Innovation in Nuclear (GAIN) initiative between PNNL and Flibe Energy to establish the viability of designing an improved approach to noble gas management. See an abstract on the project.