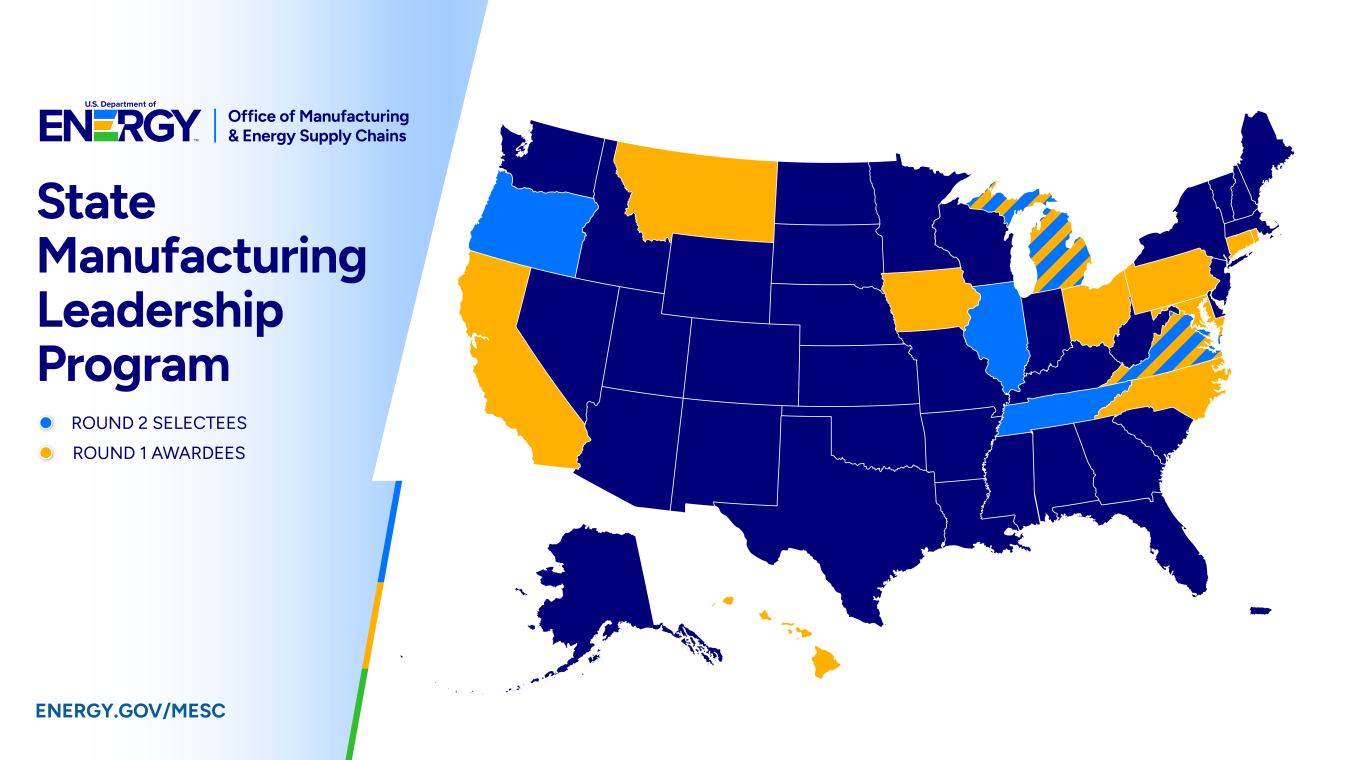

The U.S. Department of Energy, through the Office of Manufacturing and Energy Supply Chains (MESC), is partnering with states to accelerate the adoption of smart manufacturing and high-performance computing technologies across their small- and medium-sized manufacturing (SMM) firm base.

The State Manufacturing Leadership Program will connect SMMs broadly with resources for utilizing smart manufacturing technologies in their facilities. "Smart manufacturing" refers to the use of emerging and advanced technologies—such as advanced sensors, data analytics, and process control—to increase the efficiency of traditional manufacturing processes. By adopting smart manufacturing technologies, firms can lower costs, increase energy efficiency and performance, reduce material demand, and improve product quality.

In November 2024, DOE announced the selection of five states for award negotiation to receive $9.3 million to establish or expand programs that accelerate adoption of smart manufacturing and high-performance computing technologies by SMMs. These selections will give SMMs access to beneficial resources such as technical assistance, training, facility assessments, apprenticeships, and financial assistance. The first round of selections under the State Manufacturing Leadership Program were announced on September 27, 2023.

Learn more about the portfolio below

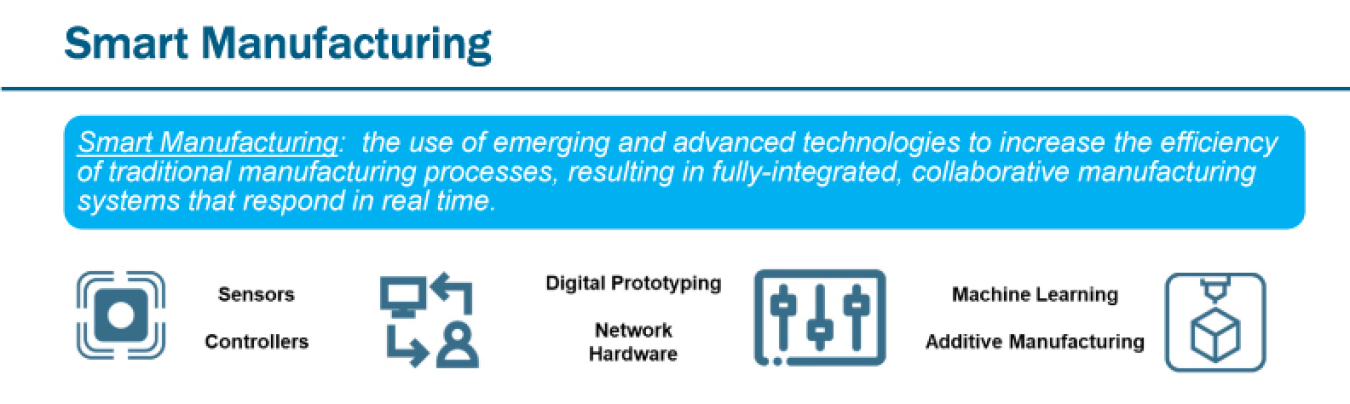

What is Smart Manufacturing?

Smart manufacturing is the use of emerging and advanced technologies to increase the efficiency of the traditional manufacturing process. Smart manufacturing produces fully-integrated, collaborative manufacturing systems that respond in real time to meet changing demands and conditions in the factory, in the supply network, and in customer needs. Rather than each machine and product line operating independently and remotely, smart manufacturing technology can cause machines and operators to communicate with each other—through digitization, automation, and artificial intelligence—helping manufacturers track and anticipate problems, and create efficiencies and optimized processes.

Smart manufacturing technologies play a key role in increasing energy efficiency and performance, including by modeling, simulating, and optimizing energy efficiency and energy performance of buildings and manufacturing plants; and modeling, simulating, and optimizing the design of energy efficient and sustainable products, including through the use of digital prototyping and additive manufacturing to enhance product design.

In smart manufacturing, organizations, people, and technology work in synergy. Smart manufacturing is radically impacting the performance of the manufacturing ecosystem through measurable improvements in areas such as speed, agility, innovation, quality, costs/profitability, safety, asset reliability, and energy productivity.

Smart Manufacturing

Smart ManufacturingWhat is High-Performance Computing?

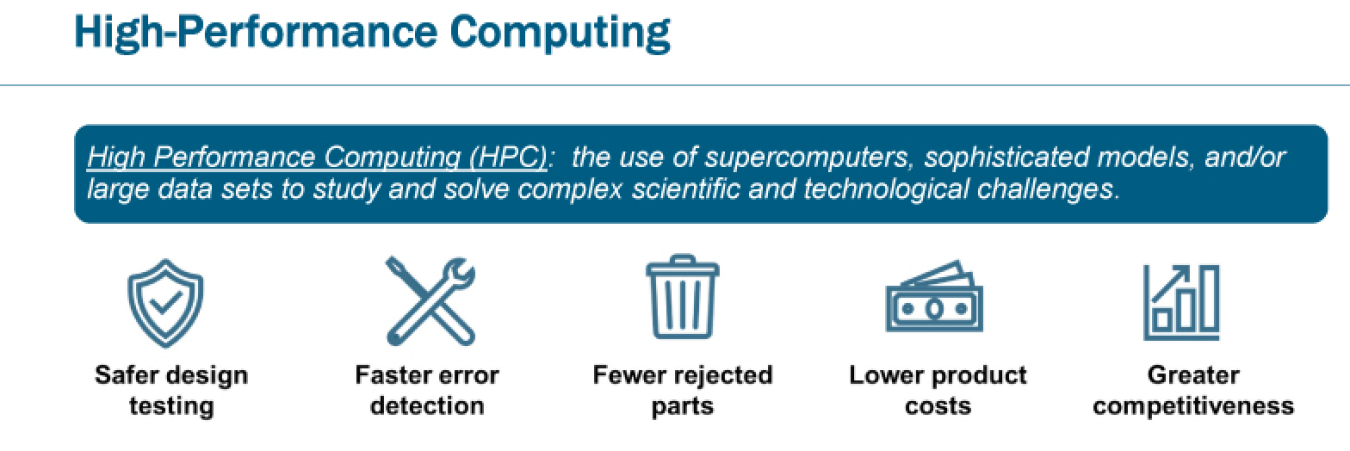

High-performance computing (HPC) is the use of supercomputers, sophisticated models, and/or large data sets to study and solve complex scientific and technological challenges. Manufacturers have long relied on computers for modeling during process and product development and in-plant troubleshooting. Recent increases in computer processing power have enabled dramatically faster and more accurate modeling, simulation, and data analysis.

In manufacturing, HPC is used to develop advanced materials and manufacturing processes. These HPC capabilities can be applied by small- and medium-sized manufacturers to:

- Model and simulate the operation of highly complex processes and advanced technologies;

- Accurately predict the effects from changing design configurations;

- Rapidly analyze huge data sets;

- Gain a deeper understanding of the underlying physical behavior to inform decision-making;

- Lower energy and material use and costs; and

- Improve manufacturing line performance, increase energy efficiency, and cut emissions.

Round 2 Selectees

Illinois Department of Commerce and Economic Opportunity

Project Title: Smart Manufacturing Lighthouse Program

Project Location: Illinois

Federal Cost Share: $2,000,000

Status: SelectedPROJECT OVERVIEW

The Illinois Department of Commerce and Economic Opportunity (DCEO) will support the Illinois Climate and Equitable Jobs Act through the Smart Manufacturing Lighthouse Program (SMLP). The objective of SMLP is to accelerate the adoption of smart manufacturing technologies among small- and medium-sized manufacturers (SMMs) in Illinois, focusing on enhancing economic competitiveness, efficiency, and energy productivity. The program will provide a range of services, including training, workforce development, technology showcases, and direct implementation, to drive smart manufacturing across the state. 30 manufacturers will demonstrate the applications of smart technology and act as beacons of best practice for other manufacturers. The possibilities of high-performance computing in SMMs will be explored in a pilot program partnering with Argonne National Laboratory.

COMMUNITY IMPACTS

The Smart Manufacturing Lighthouse Program (SMLP) will utilize the full ecosystem of partners including local community and labor groups to provide resources, outreach, technical assistance, financial assistance, or workforce and training support. The program expects to train 200 individuals in smart technologies and provide them with new in-demand skills and pilot a smart manufacturing intern corps. SMLP will help advance the goals of the Climate and Equitable Jobs Act by providing support around technology adoption and reducing energy burden to SMMs and workforce development partners.

Smart Manufacturing Technology Roadmapping: Award 30 manufacturers competitive grants to roadmap and implement best-in-class smart manufacturing practices.

Michigan Strategic Fund

Project Title: Project DIAMOnD Statewide Expansion: Distributed, Independent, Agile, Manufacturing on Demand

Project Location: Michigan

Federal Cost Share: $1,999,400

Status: SelectedPROJECT OVERVIEW

The Michigan Strategic Fund (MSF) will expand Project DIAMOnD (Distributed, Independent, Agile Manufacturing On Demand) statewide to support small- and medium- sized manufacturers (SMMs) in adopting smart manufacturing technologies. Originally launched in Oakland County by Automation Alley, Project DIAMOnD established a network of over 300 SMMs with access to advanced technologies and training through the Digital Transformation Program (DTP) and Digital Transformation Center (DTC). The statewide expansion beyond Oakland County empowers SMMs with advanced smart manufacturing technologies and workforce development opportunities through training, technology implementation, and network growth throughout the state. The project will enhance SMMs' capabilities in additive manufacturing and strengthen supply chain resilience resulting in improved energy efficiency and emissions reduction, contributing to Michigan's leadership in advanced manufacturing.

COMMUNITY IMPACTS

Through this expansion of Project DIAMOnD, 100 SMMs will be provided with product/process assessments and receive training/workshops in additive manufacturing to learn the fundamentals and identify business opportunities. Free access to software that allows for optimizing and prototyping products through additive technologies. The major participants for this project include Automation Alley, (Subrecipient); Michigan Manufacturing Technology Center (Michigan MEP); and Geofabrica (Industry Partner).

Smart Manufacturing Technology Roadmapping: Tailored smart manufacturing technology roadmaps to guide the assessment, selection, and implementation of advanced technologies to optimize energy efficiency and drive new business opportunities.

Oregon Business Development Department

Project Title: Oregon Smart Manufacturing Initiative (OSMI)

Project Location: Oregon

Federal Cost Share: $2,000,000

Status: SelectedPROJECT OVERVIEW

The objective of the Oregon State Manufacturing Initiative (OSMI) is to rapidly deploy technical assistance and direct business investment to advance Smart Manufacturing implementation across Oregon by small- and medium-sized manufacturers (SMMs). Oregon’s approach will modernize manufacturing facilities, increase targeted sector competitiveness, improve company profitability, and improve workplace environments. The OSMI project demonstrates pathways for private-public partnership to drive innovation and help the state meet its energy transition goals while advancing economic and business competitiveness for Oregon manufacturers. Business Oregon will administer the funds to deploy direct business investments, enhance agency initiatives, and provide technical assistance to stakeholders.

COMMUNITY IMPACTS

The OSMI project will work closely with tribal partners and community-based organizations in the development, delivery, and implementation. The primary focus of the project is to complete 20 facility, product, or process assessments targeting SMMs/industries/geographies. The project will make approximately $1.3 million of direct financing available to SMMs to be able to implement Smart Manufacturing Technologies for approximately 30-40 SMM-qualified projects. The major participants and key partners for this project include the Oregon Manufacturing Extension Partnership, Center for Sustainable Infrastructure, Oregon Department of Energy, and Higher Education Coordination Commission.

Smart Manufacturing Technology Roadmapping: Complete 20 facility, product, or process assessments targeting SMMs.

Tennessee Department of Environment and Conservation

Project Title: Tennessee Partnership for Smart Manufacturing (TPSM)

Project Location: Tennessee

Federal Cost Share: $1,700,032

Status: SelectedPROJECT OVERVIEW

The Tennessee Partnership for Smart Manufacturing (TPSM) is a coalition of partners that will work together to extensively deliver smart manufacturing and high-performance computing (HPC) awareness and outreach, education and training, assessments and roadmapping, assistance in implementation and operations, and continuous improvement tailored to the needs of small- and medium-sized manufacturers (SMMs) across Tennessee. The goal of TPSM is to assist Tennessee SMMs with implementing smart manufacturing and use of high-performance computing to optimize production, reduce costs, reduce energy consumption and carbon emissions, while training the existing SMM workforce and next generation of SMM workers on these technologies.

COMMUNITY IMPACTS

TPSM is committed to providing well-paying, stable jobs for Tennesseans. TPSM will expose engineering and other students to SMMs, help students identify opportunities, and encourage them to join SMMs. The program will revolutionize 32 unique manufacturing facilities through advanced sensor utilization, computing capabilities, simulation, optimization, and other SM technologies through receiving comprehensive TPSM technical assessments. The major participants and key partners of this project include The Tennessee Department of Environment and Conservation – Office of Sustainable Practices (TDEC OSP), Tennessee Tech University, University of Tennessee Knoxville, University of Memphis, and Tennessee Manufacturing Extension Program (MEP).

Smart Manufacturing Technology Roadmapping: 10 manufacturing facilities will receive executable plans to implement smart manufacturing improvements through detailed "roadmapping" services.

GENEDGE Alliance

Project Title: Virginia Smart Manufacturing Accelerator 2 (VSMA 2)

Project Location: Virginia

Federal Cost Share: $1,650,000

Status: SelectedPROJECT OVERVIEW

The objective of the project is to fully stand up the Virginia Smart Manufacturing Accelerator (VSMA) www.vsma.tech as the go to resource in Virginia to address smart manufacturing opportunities with small- and medium-sized manufacturers (SMMs). GENEDGE Alliance intends to continue the work begun in the current effort, with a drive towards self-sufficiency through significant state matching funds, and program income. The expansion includes a new Smart Manufacturing Technician Apprenticeship product, with registration through Virginia Works, to service multiple companies. GENEDGE Alliance will accelerate the deployment of Smart Manufacturing Technologies (SMT) with small- and medium-sized manufacturers (SMMs) in Virginia. The project will enable SMMs to work together continuously and to democratize the use of The Commonwealth of Virginia’s high-performance computing (HPC) assets. Implementation services will expand, including services provided by our subrecipient (SRA) partners.

COMMUNITY IMPACTS

This effort develops a new Smart Manufacturing Technician apprenticeship program, and develops custom registered programs, utilizing the curricula developed by Old Dominion University, and vetted through Virginia Works, which manages the Virginia state program. Contract and deliver assessments to clients to provide meaningful assistance in the application of specific technologies, such as energy management, economy of operations, and environmental excellence. The major SRAs for this project include Commonwealth Center for Advanced Manufacturing, Old Dominion University, Virginia Commonwealth University, Virginia Manufacturers Association and Virginia State University, and Virginia Tech. Collaborative partners include the Virginia Economic Development Partnership, Virginia Dept of Housing & Community Development – GO Virginia, Virginia Dept. of Small Business & Supplier Diversity, Virginia Works, and VCCS.

Smart Manufacturing Technology Roadmapping: Contract and deliver smart manufacturing roadmap assistance to clients, to determine applications of those technologies to improve operations, product and process development efficiency and effectiveness. Targeting technology roadmaps created in DAC areas.

Round 1 Selectees

California Governor’s Office of Planning & Research

Project Title: California Smart Manufacturing Leadership Program (CA SMLP)

Project Location: California

Federal Share: $2,000,000

Recipient Cost Match: $782,910

Status: AwardedPROJECT OVERVIEW

California’s Smart Manufacturing Leadership Program will educate and guide small- and medium-sized manufacturers (SMMs) in the adoption of smart manufacturing technologies and methodologies to be more resilient and globally competitive. Their program will create awareness of the value and benefits of smart manufacturing through education and outreach and will offer smart manufacturing boot camps, pre-apprenticeships and apprenticeships, and upskilling of existing SMMs’ workforce as well as provide technical assistance to help SMMs adopt smart manufacturing technology and provide energy and smart manufacturing assessments. The program is partnering with numerous community partners and community colleges as well as two Industrial Assessment Centers and the CESMII Smart Manufacturing Institute, and will focus support in the Bay Area, Los Angeles, and San Diego, with the goal of expanding advanced manufacturing job opportunities to historically underrepresented groups.

Connecticut’s Department of Economic and Community

Project Title: Connecticut’s Smart Manufacturing Assessment and Access to Reduce Technology Emissions (CT SMARTE)

Project Location: Connecticut

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Connecticut’s Smart Manufacturing Assessment and Access to Reduce Technology Emissions (CT SMARTE) will accelerate the deployment and adoption of smart manufacturing and High-Performance Computing (HPC) technologies for SMMs in disadvantaged areas. Through leveraging existing relationships with industry, academic, technology, and community partners, to include the state’s NIST MEP center, Connecticut Center for Advanced Technology Inc. (CCAT), and Industrial Assessment Center at the University of Connecticut, the program will support SMMs to increase efficiency, productivity and reduce energy consumption and costs through implementation of smart manufacturing and HPC technologies. The program will focus on supporting the green energy, aerospace and defense, and semiconductor industries based on their high impact on the environment and economy in the state.

INNOVATE Hawaii

Project Title: Hawaii’s Smart Manufacturing Training Program

Project Location: Hawaii

Federal Share: $1,054,012

Recipient Cost Match: $451,720

Status: AwardedPROJECT OVERVIEW

Hawaii’s Smart Manufacturing Training Program, led by INNOVATE Hawaii, the state’s NIST MEP Center, plans to support SMMs in all Hawaii counties to adopt smart manufacturing to meet the current and future needs for SMMs to expand their business and improve their energy use. The program’s primary goal is to provide workforce training to Hawaiian SMMs and their employees on the operation and maintenance of smart manufacturing technology and new automation processes and aims to educate SMMs on the benefits and energy saving efficiencies of transitioning into smart manufacturing. The program will provide a variety of training and technical assistance services in the form of workshops, one-on-one counseling, and virtual and in-person seminars. This program will aid the State in reducing Hawaii’s carbon footprint and may provide energy alternatives and energy reduction within SMMs to help cut the costs of utilities.

Iowa’s Economic Development Authority

Project Title: Smart Manufacturing Capacity Building in Iowa

Project Location: Iowa

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Iowa’s Economic Development Authority project will increase access to emerging smart manufacturing and high-performance computing (HPC) resources for SMMs through technical assistance, workforce training opportunities and needs assessments. The project will provide foundational systems and software resources to SMMs by conducting assessments and systems mapping, deploying demonstrations, and providing technical assistance in support of solution deployment. The project will also develop and deploy capacity to serve more advanced technologies in digital twins, artificial intelligence, cybersecurity, and connected factories through demonstrations, community college training, and technical assistance. These actions will improve the competitiveness of Iowa manufacturing, reduce industrial emissions, provide workforce development opportunities, and continue to advance the manufacturing technology ecosystem in the state.

Maryland’s Department of Commerce

Project Title: Manufacturing Asset Deployment for Energy (MADE 4.0)

Project Location: Maryland

Federal Share: $1,010,000

Recipient Cost Match: $305,000

Status: AwardedPROJECT OVERVIEW

Maryland’s Manufacturing Asset Deployment for Energy (MADE 4.0) Program will support SMMs across the state through a combination of smart manufacturing technology applications and community workforce training, leading to energy, production, and quality efficiency gains in their facilities. The program will create and convene a consortium of public, private, nonprofit, and higher education partners to conduct outreach and provide seminars, workshops, and online training for SMMs and their employees. The program will also provide grants to 15 SMMs to implement smart manufacturing technology improvements.

Michigan Strategic Fund

Project Title: Michigan’s Industry 4.0 (I4.0) Signature Initiative

Project Location: Michigan

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Michigan is expanding upon its existing Industry 4.0 (I4.0) Signature Initiative program to provide financial assistance to implement smart manufacturing projects for 83-100 SMMs across the state. Since its launch in December 2020, the I4.0 Signature Initiative has already supported over 2,500 SMMs through more than 7,700 activities including course training, I4.0 readiness assessments, business analyses, and implementation grants.

Montana’s Department of Environmental Quality - State Energy Office

Project Title: Smart Manufacturing Technologies Outreach Initiative

Project Location: Montana

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Montana’s Smart Manufacturing Technologies Outreach Initiative will support SMMs across the state accelerate the implementation of smart manufacturing technologies in their operations. The program will build and deploy a smart manufacturing demonstration and simulation unit to provide on-site demonstrations for SMMs throughout the state, educating them on available smart manufacturing technologies and how they could improve facility operations and efficiency. The program will also create apprenticeship and internship programs and is partnering with Highlands College to develop a Smart Manufacturing Technician certificate program.

North Carolina’s Department of Commerce: Office of Science, Technology & Innovation

Project Title: Smart Manufacturing Adoption to Realize Transformative Energy Reductions for North Carolina (SMARTER NC)

Project Location: North Carolina

Federal Share: $1,946,320

Recipient Cost Match: $583,897

Status: AwardedPROJECT OVERVIEW

North Carolina’s Smart Manufacturing Adoption to Realize Transformative Energy Reductions for North Carolina (SMARTER NC) aims to increase productivity and efficiency of NC SMMs by providing targeted technical assistance, increasing awareness, access to, and implementation of smart manufacturing technologies. By establishing an innovative and collaborative resource ecosystem, partners will be able to help support 500 participating SMMs close identified gaps in their digital transformation journey. SMMs to be targeted will align with high energy consumption manufacturing sectors within the state, such as: biopharmaceutical manufacturing, metal fabrication, chemical and polymer manufacturing, food and beverage manufacturing, automotive and heavy equipment manufacturing, and textiles. The program will work with a variety of partners to include the state’s NIST MEP and the Smart Manufacturing Innovation Center (SMIC) at NC State University.

Ohio Department of Development

Project Title: Smart and Clean Manufacturing Leadership

Program Location: Ohio

Federal Share: $1,999,922

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Ohio’s Smart and Clean Manufacturing Leadership Program is undertaking a three-pronged approach to support SMMs access and benefit from smart manufacturing technologies. Through conducting outreach and training, providing smart manufacturing assessments, and implementing smart and clean technology adoption and process improvements, the program will decrease the energy burden and increase energy efficiency for the state’s SMMs. The program aims to support at least 20 SMMs with smart manufacturing improvement projects. The program will also work close with the Industrial Assessment Center at the University of Dayton, the state’s NIST MEP, and the CESMII Smart Manufacturing Institute to develop robust assessment tools to improve the analyses and recommendations made to SMMs to implement smart and clean technologies.

Pennsylvania Department of Community & Economic Development

Project Title: Smart Manufacturing and Advanced Retooling Team for Pennsylvania (SMART PA)

Project Location: Pennsylvania

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

Pennsylvania’s Smart Manufacturing and Advanced Retooling Team for Pennsylvania (SMART PA) will use the statewide network of seven (7) NIST MEP affiliates and Penn State University’s "Digital Foundry" to support 1,400 SMMs through a robust assistance program for manufacturers and workers for the evaluation and deployment of smart manufacturing technologies and high-performance computing tools on Pennsylvania’s factory floors. SMART PA is supported by the CESMII Smart Manufacturing Institute and guided by community benefits and labor organizations such as the United Steel Workers, the Eastern Minority Supplier Development Council, and Reimagine Appalachia. SMART PA will complement and leverage PA’s existing "Manufacturing PA" and industrial decarbonization programs to reduce the energy use and carbon footprints of Pennsylvania factories while boosting manufacturing expansion and family-wage jobs.

Rhode Island Commerce Corporation

Project Title: Smart Advancements for the Rhode Island Manufacturing Ecosystem

Project Location: Rhode Island

Federal Share: $1,998,788

Recipient Cost Match: $601,000

Status: AwardedPROJECT OVERVIEW

Rhode Island Commerce Corporation’s project will support SMMs through expanding the ecosystem of available smart manufacturing and HPC resource partners in the state and providing direct assistance to SMMs. The project will offer a variety of services to SMMs such as smart manufacturing assessments, roadmaps, economic impact surveys, training and upskilling of new and incumbent workers, and financial assistance to facilitate access to and implementation of smart manufacturing and HPC solutions. The project is leveraging an existing ecosystem of partners to include Polaris, the state’s NIST MEP center as well as several Manufacturing USA Institutes.

GENEDGE Alliance (VA’s NIST-MEP Center)

Project Title: Virginia SMART Manufacturing Accelerator (VSMA)

Project Location: Virginia

Federal Share: $2,000,000

Recipient Cost Match: $600,000

Status: AwardedPROJECT OVERVIEW

The Virginia SMART Manufacturing Accelerator (VSMA)s program, led by GENEDGE Alliance, Virginia’s NIST MEP Center, will accelerate deployment of smart manufacturing technologies with SMMs in Virginia, to digitally connect and manage manufacturing systems in their facilities and supply chains to work together continuously, and to democratize the use of Commonwealth high-performance computing (HPC) assets to enable SMMs to utilize modeling, simulation, and big data. The HPC will enable SMMs to obtain better capital return on investment using digital twin simulation-based decision making, improve manufacturing line performance, increase energy efficiency, cut emissions, and design and deliver more sustainable products. The project will work with a variety of community partners, universities, HBCUs, community colleges, and technical partners to assist over 200 SMMs through workshops, webinars, smart manufacturing assessments and technology implementation.