Two-year project required 49,000 work hours and was completed with no safety issues

February 29, 2024

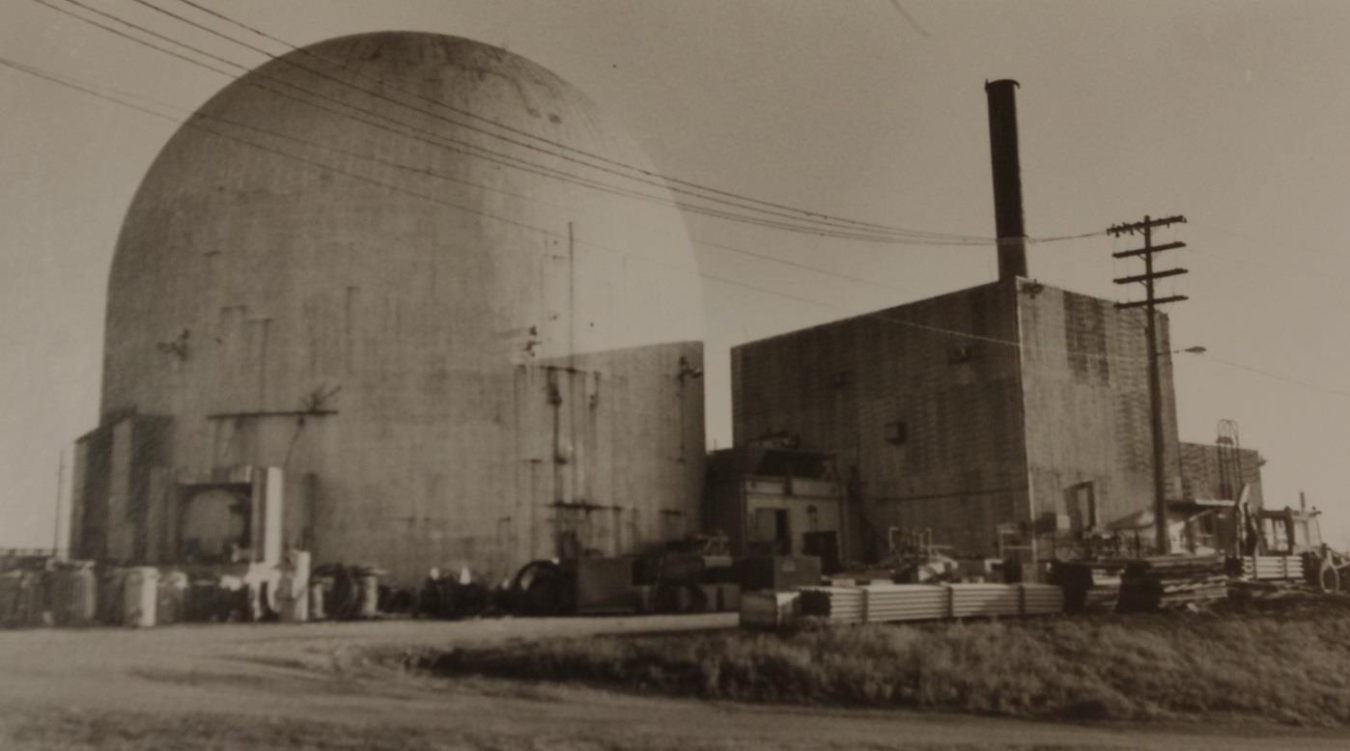

In southwestern Ohio, about 30 miles north of Dayton, is the small town of Piqua. In fall 2023, the U.S. Department of Energy’s Office of Legacy Management (LM) demolished a decommissioned nuclear reactor site that had been part of the town since the 1960s.

Demolishing a former nuclear reactor site isn’t exactly easy. You can’t just take a sledgehammer to the 18-inch-thick concrete dome. The successful project took nearly two years to complete and required careful planning and leadership from a team of experts willing to adapt to an ever-changing situation, and the result took more than 49,000 work hours, without a safety incident.

The organically moderated reactor, originally built in the 1960s, was part of the U.S. Atomic Energy Commission’s (AEC) Power Demonstration Reactor Program to explore peaceful applications of nuclear technology. The reactor operated for about two years before it was shut down and decommissioned. During the decommissioning process, the AEC removed parts of the reactor, such as the reactor fuel and coolant, containing higher radioactivity. Then, they sealed the reactor vessel and nonremovable parts in place with concrete. The city of Piqua maintained the site and used the adjoining buildings for administrative offices and storage until 2018, when the city notified LM that near- and long-term maintenance costs at the site were much greater than anticipated, and they were no longer interested in using the facility.

“This is a really good example of why LM exists as an organization,” said LM Piqua Site Manager Brian Zimmerman. “Long-term stewardship is not passive; it’s active. Sites, stakeholders, societies, and values evolve over time. We’re here to oversee the remedy and protect human health and the environment over time.”

In this case, the best way to do that was to demolish the site. This task was assigned to LM contractor Demolition Project Manager David Parker and Deputy Project Manager Amy Jones, who would see the project through from concept to completion.

“We had to write the demolition plan in chapters,” said Parker. “It happens when dealing with the complexities of a project like this. The situation was ever evolving. It was daunting at times, but taking a step-by-step approach helped us stay focused, remain fluid, consult with experts, make appropriate adjustments, and keep moving.”

Every project can have hiccups, and the Piqua reactor demolition was no exception. During the demolition, crews found an unidentified drum in a storage vault, discovered more asbestos than originally detected, realized the dome was thicker and stronger than originally thought, and navigated logistical challenges such as moving large construction equipment around on a small project area.

“In each case, the team didn’t hesitate to pause, reevaluate, discuss as a team, go back through all the appropriate reviews and approvals, and resume work when safety and integrity could be upheld,” Zimmerman said. “That really demonstrates a strong safety culture. Everyone was committed to upholding the highest standards. The contractor team in the field were seasoned professionals and empowered to identify issues. They felt comfortable bringing those issues up, and everyone in the management chain was responsive to assessing them.”

Deconstruction of the dome.

With up to 20 people on-site at a time, each person played a part in maintaining safety culture.

“One of the key elements to the success at Piqua was the safety professionals on site,” Jones said. “They kept the focus on safety. Every conversation was about safety. There was a strong expectation that everyone would uphold those practices.”

The project included a range of changing activities and hazards, including torch cutting, working at heights, using scaffolding and ladders, saw cutting, controlling falling debris, operating equipment, remediating hazardous waste, and managing construction traffic. All activities were monitored by on-site contractor and subcontractor safety representatives.

“We all had an equal say in what safety looked like on a daily basis,” Parker said. “It was an extremely collaborative approach. Everyone there had a right to talk about how we were going to stay safe, and to bring up any concerns. We were keeping the main thing ‘the main thing,’ and that was safety.”

“Our goal is for everyone to go home,” Jones said. “If the safety culture is truly built into the process, it’s so natural that you don’t think about it as being something added and becoming tedious. If someone gets caught up in the tedium, someone else will bring them back. That team focus and support is key.”

For Parker, the team’s focus and support was clear, and people working together respectfully made all the difference. “We had a core group of people who were committed to working with the fluidity of the project. They knew things would change, accepted it, and worked through it.” He said he knew there were people he could call on at any time to offer their perspective.

“We worked through various alternatives and potential solutions, including solicitation of varying ideas,” Parker said. “Although opinions differed at times, we all had the same safety goals and were committed to them. Working with a team like that was invaluable.”

So, what did the team learn about leadership on this project?

“Leadership doesn’t have to come from the top,” Zimmerman said. “I was impressed by the empowerment of everyone on the project, and how the leadership and respect flowed in both directions. That made the project successful.”

Jones, who joined the project later, praised Parker and the team for establishing focus and commitment early on. She said, “There was a great foundation from the start, so by the time I came on the team they were already formed and working well together, and the focus was clear.”

Parker agreed that the team-based approach helped ensure project success.

“If you can all stay focused, agree, and know and accept that things will come up, and have respect for each other, at the end of the day, you can get through anything,” he said.

The Piqua project had several moving parts. In their commitment to transparency, LM and the contractor personnel provided an outreach plan and communicated regularly with city officials and residents. They used controls on-site to make sure the public and community remained safe. The planning stage was critical, and teams addressed unexpected circumstances with unwavering commitment to safety and quality. Everyone on-site, including 12 different subcontractor groups, voiced their concerns and worked together to find solutions as a standard practice. The mutual respect shown by everyone working on the project empowered each person to stay physically and psychologically safe.

The project was officially declared complete in November 2023, after successfully removing and disposing of industrial and hazardous waste, demolishing the dome and auxiliary building, enclosing the entombed core beneath a 10-foot-thick concrete barrier, and paving a parking lot for the city to use in the future.

Jay Glascock, LM’s director for site operations said, “The entire team did a great job. This was not an easy project, and this type of work is not something we do every day. The team should be commended for successfully and safely completing this major project. Their ability to work together, overcome challenges, and keep everyone safe, while informing the local community along the way, was tremendous.”