This content explores the regions in the United States facing the highest wildfire risks and provides an overview of the diverse strategies available to photovoltaic (PV) system professionals, including designers, installers, owners, and operators, to effectively manage this risk.

These strategies encompass the entire PV system lifecycle, ranging from initial design considerations to post-damage assessments. In instances where existing approaches may be insufficient, this content raises critical research questions to further explore and enhance wildfire mitigation measures.

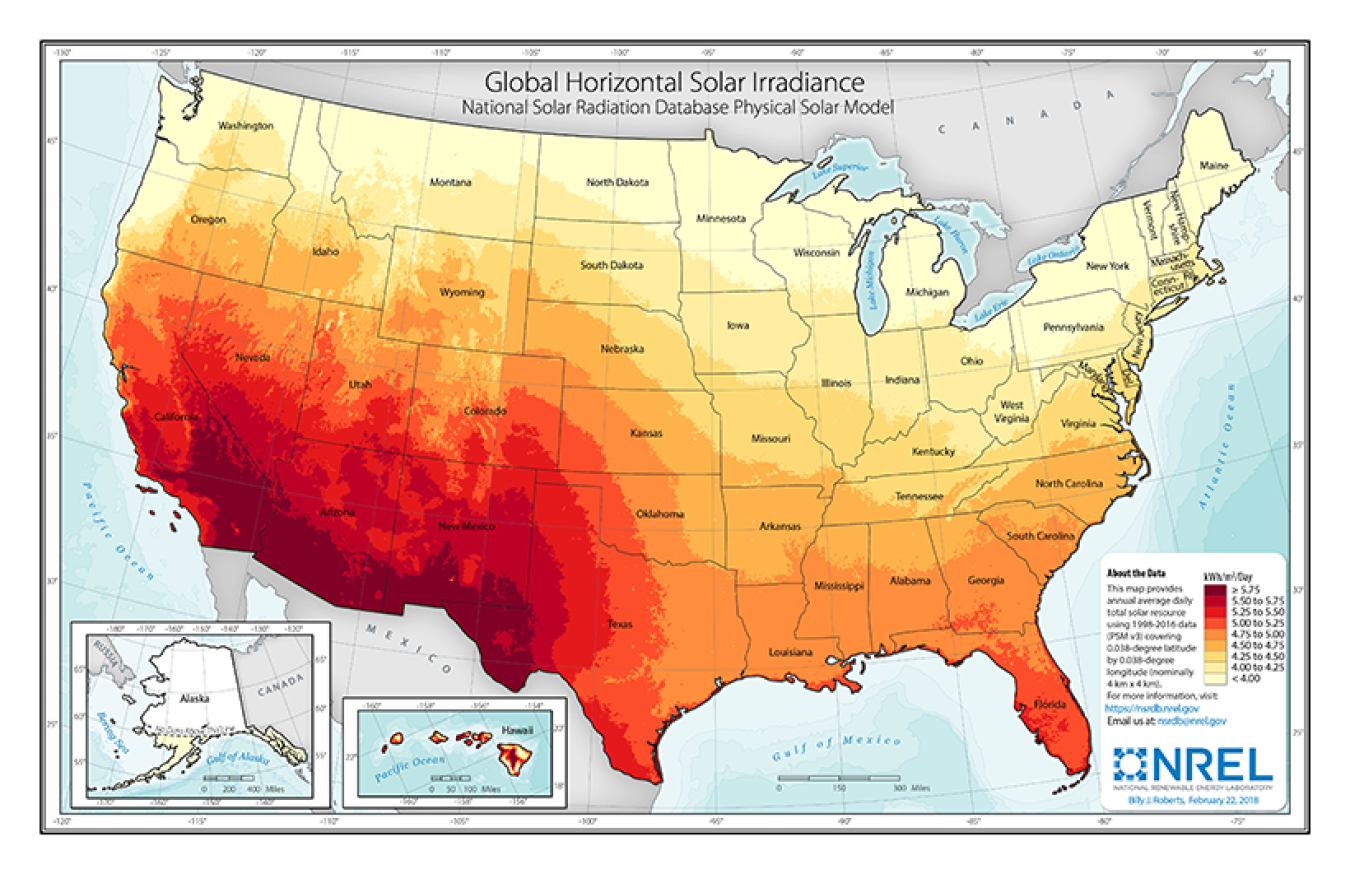

Figure 1. Total Solar Resource Availability in the United States

The National Renewable Energy Laboratory's National Solar Radiation Database shows that solar PV systems are best able to reliably take advantage of the sun's energy in the Southwestern United States. Figure 1 shows the areas with highest solar resource in the United States.

These same areas are also among the most wildfire-prone areas in the country. The threat of wildfire can pose long-term survivability challenges for solar PV systems in these areas and limit power production.

Risk Profile

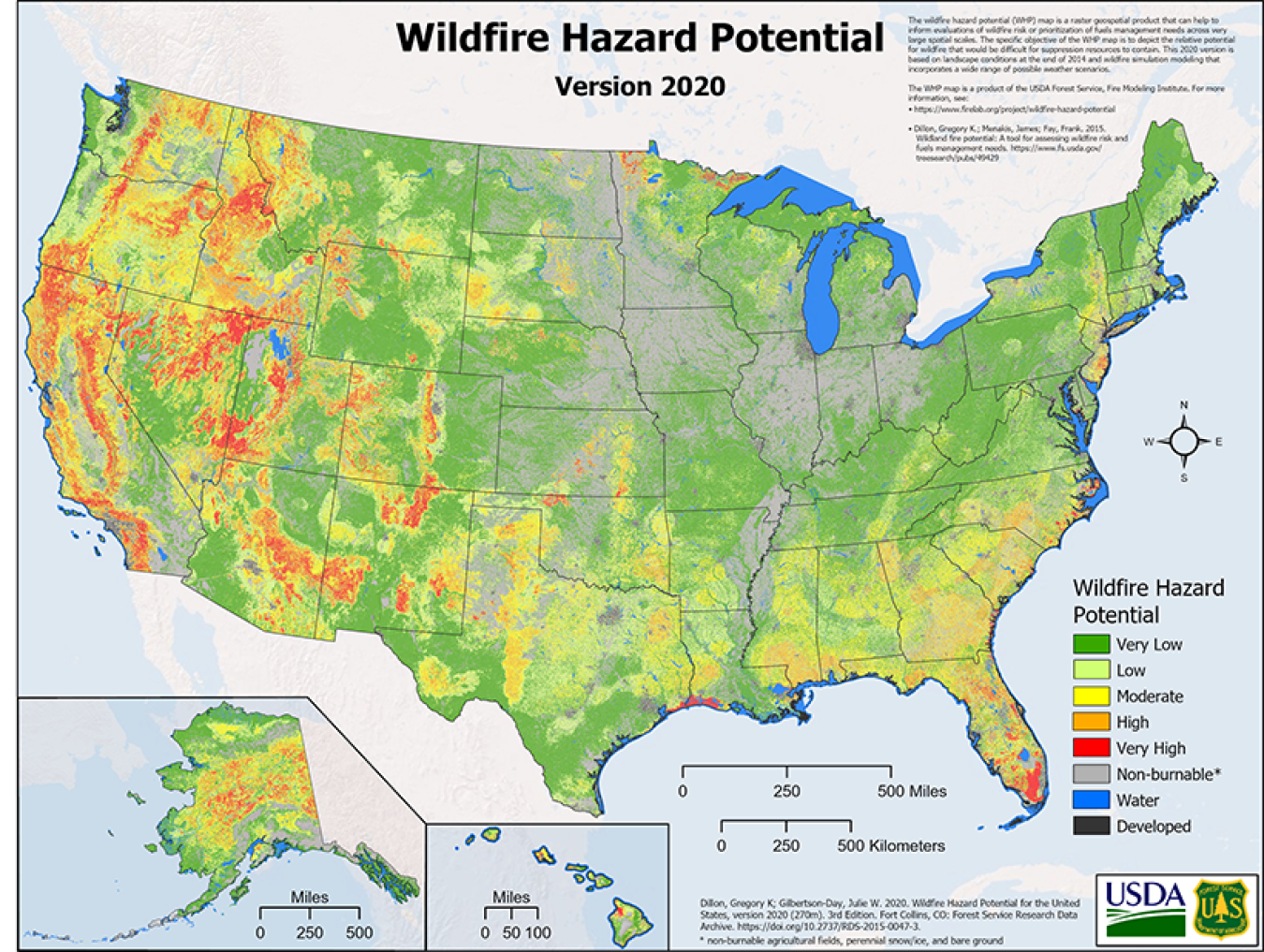

Generally, most locations in the United States have some degree of wildfire hazard potential. Figure 2 shows the areas of the United States by their wildfire hazard potential, from "Very Low" to "Very High".

The highest fire risk in the United States occurs in the West, mainly in the mountainous and forested areas occurring west of the Rocky Mountains (i.e., in Arizona, California, Colorado, Idaho, Montana, Nevada, New Mexico, Oregon, Utah, Wyoming, and Washington).

The exceptions to this pattern are mostly large wetlands in the southern and southeastern United States or unique ecosystems with high fuel volumes near large bodies of water (i.e., dispersed areas throughout the Hawaiian Islands and the Alaskan Interior, the Gulf Coast-facing border of Texas and Louisiana, the Everglades in southern Florida, the Outer Banks of North Carolina, central New Jersey, and northern Minnesota).

The southern and southeastern United States generally have the next highest risk levels of wildfire hazard potential after the western region. Significant sections of Alabama, Florida, Georgia, Mississippi, and the Carolinas report having a "Moderate" or "High" risk of wildfire hazard.

Given that nearly nine in 10 wildfires are caused or started by humans rather than natural phenomena, any area with dry vegetation has some degree of risk of catching fire but the areas with "Very High" risk are those with enough fuel to keep wildfires burning and expanding.

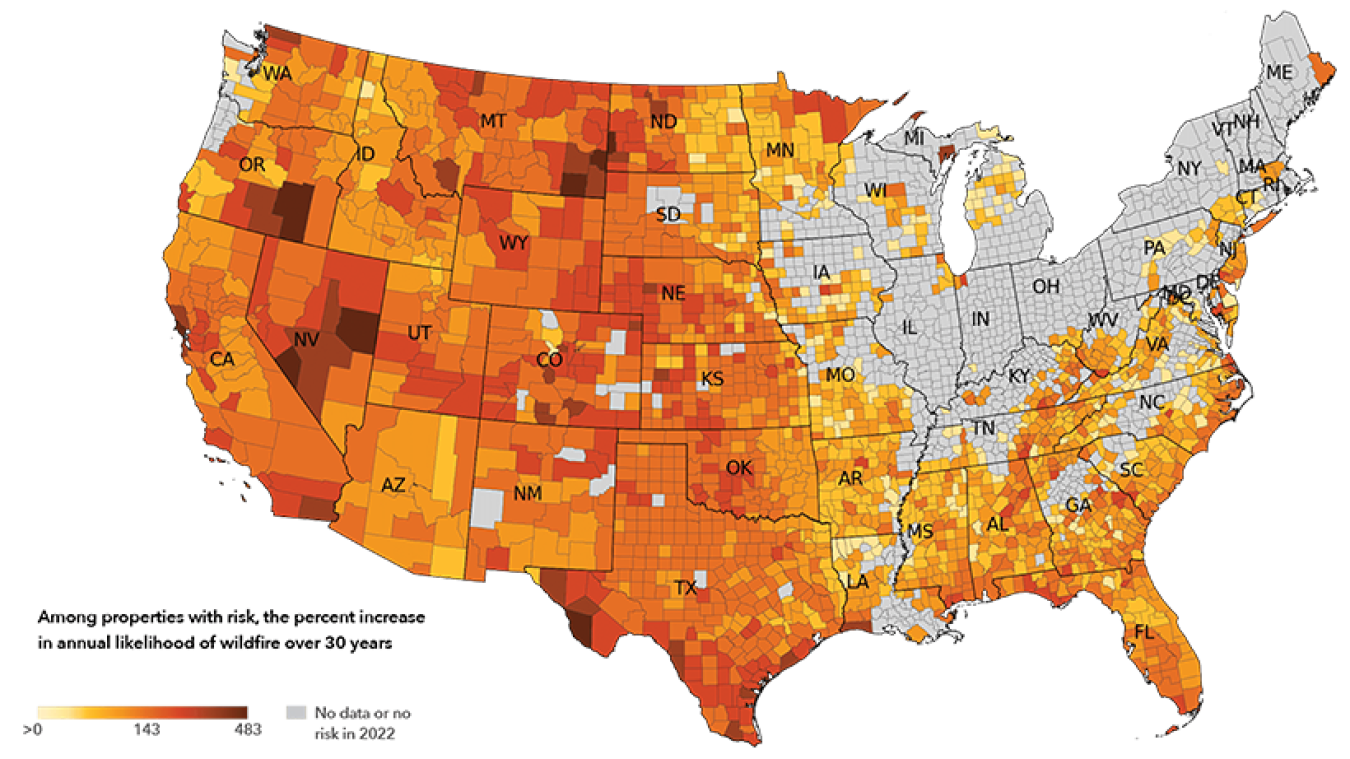

Climate change is expected to escalate the scope and intensity of wildfire events in the United States. By 2050, wildfires may expand both in terms of the area they consume and the duration they persist, leading to heightened levels of airborne pollution and an increased frequency of occurrence.

These data suggest that solar PV systems will be more vulnerable to being affected or destroyed by wildfires. Figure 3 shows the relative increase in wildfire probability by county in the United States. This map shows that most severe increases in wildfire probability will occur in parts of California, Nevada, North Dakota, Montana, Oregon, and Texas.

Risks to Solar Photovoltaic Systems

Two primary risks are associated with wildfire hazards for PV systems. The first involves the buildup of ash and particulate matter in the atmosphere and on PV modules, which can disrupt the power generation of these systems. The second risk pertains to the potential destruction of PV systems themselves if a wildfire spreads rapidly and engulfs them.

Loss in Production

Smoke produced by wildfires can travel hundreds of miles or more from the site of a wildfire and impact the air quality and sunlight available in an area. As a result, wildfires can affect PV systems that are a great distance away from the site of burning through reduced power output and lost revenue.

Among the PV Reliability Operations and Maintenance (PVROM) dataset sites in the western United States (i.e., Arizona, California, Idaho, Nevada, New Mexico, Utah), wildfire smoke caused a measured drop from 9.4% to 37.8% in power production.

Other research covering wildfires in California in September 2020 shows that power output by PV declined between 10% to 30% on the statewide scale but declined up to 58% locally.

Even if wildfires leave PV systems physically undamaged, they can cause their operators to lose significant amounts of electricity generation and revenue.

Destruction of Modules and Materials

Wildfires also can also set PV systems aflame or melt system components, damaging or destroying them.

The average temperature of a forest fire is approximately 1,470 degrees Fahrenheit (°F) and extreme forest fires can reach temperatures as high as 2,000°F.

The melting point of aluminum, a key material in PV modules, is approximately 1,220°F, well below both the average and maximum temperatures achievable by forest-burning wildfires.

The silicon that serves as the semi-conductor material in most PV cells has a much higher melting point of approximately 2,580°F, a point above both the average and maximum wildfire temperatures.

Solar PV modules use silver to channel the electricity produced by the semi-conductor to the panel's junction box. Silver has a melting point of approximately 1,760°F, which is above the temperature of the average fire but below temperatures of the hottest wildfire events.

Of the other main materials used in the assembly of PV modules and mountings, glass (silicon dioxide) is the least likely to see destruction by the high temperature of wildfires since it has a melting point of 3,092°F.

The more likely failure mode of the glass used in conventional PV from wildfires is thermal stress fracturing (i.e., cracking or shattering) of the glass surface caused by the heat of wildfires. Tempered glass begins to crack at temperatures as low as 554°F to 716°F. Heat-strengthened glass, typically found in bifacial modules, can experience thermal stress fracturing at temperatures of 250°F.

The mounting structure that supports ground-mounted PV uses steel, which has a melting point of 2,700°F but a structural failure ceiling of 1,000°F. Given this, even average wildfires could cause severe damage to the mounting structures that support PV systems.

Table 1 shows the minimum temperatures for either the melting points or stress failure points for the materials used in the construction of a PV system along with the average and maximum temperatures of wildfires.

Temperature Ceilings at which Materials in PV Modules See Damage

Module Materials Melting/Stress Point (°F) Likely Impacts from Average Forest Fire (1,470 °F)? Likely Impacts from Hottest Forest Fires (2,000 °F)? Aluminum1 1,220/[N/A] Yes Yes Silicon2 2,580/[N/A] No No Silver3 1,760/[N/A] No Yes Tempered Glass4 3,092/554 to 716 Yes Yes Heat-Strengthened Glass5 3,092/250 Yes Yes Steel6 2,700/1,000 Yes Yes 1National Institute of Standards and Technology

2The Pennsylvania State University, College of Earth and Mineral Sciences

Destruction of Specialized System Equipment

PV systems have specialized equipment and electronics that maintain their operations and connection to the grid that can also be damaged by wildfires. These can include specialized mechanical motors for PV systems with automated tracking and inverters that convert the direct current produced by the PV modules into alternating current.

These components are costly and may be difficult to replace quickly. For example, an inverter for a 200-kW rooftop PV system could cost $16,000 to replace.

Best Practices

This section outlines the best practices that operators, planners, and purchasers of PV systems may take to reduce the risk and impact of wildfires upon their systems in terms of module and system design, procurement, and site operations and maintenance (O&M).

System Design and Procurement

Research is currently ongoing to identify and improve the production, design, and site design for PV systems to make them more resilient to wildfires.

Although it is extremely challenging to design PV technology to protect against the exceptional and extreme wildfire events that are becoming more common with climate change, there are methods that PV system operators can use to reduce risk and mitigate damage resulting from a wildfire.

Module Selection

While some types of PV modules may resist fire better than others, all are susceptible to damage from wildfires. The siting selection and environmental management practices of the PV system's owners likely have a greater overall effect on reducing the risk of wildfire damage to a PV system than the specific kind of module.

The solar industry and its fire regulators have adopted classifications for different grades of PV modules based on their resistance to and resilience against fire events. The National Electric Code and International Building Code have created three designations of PV modules that refer to their ability to withstand fire. They include:

- Class A – for severe fire exposure; required in wildland-urban interface areas; must withstand direct burning for 10 minutes at a temperature of approximately 1,400 °F and keep flames from spreading more than six feet.

- Class B – for moderate fire exposure; typically required in built-up urban areas; must withstand burning for 10 minutes and keep flames from spreading more than eight feet.

- Class C – for light fire exposure; must withstand burning for four minutes and keep flames from spreading more than 13 feet.

In areas where Class A and B fire ratings are not required for PV systems, owners can take initiative to select these more resilient kinds of PV systems over Class C rated modules to ensure greater resilience to wildfires.

Keep in mind that even a Class A module is only rated to withstand average fire conditions for 10 minutes, so damage is certainly still possible, but that selection may reduce damage and fire spread when compared to Class C modules and may allow emergency response crews more time to respond.

| Recommendation: Use Class A fire rated modules on sites at high risk for wildfires. In any case, fire ratings of PV modules must at least match the fire rating of the roof. Require fire classifications in accordance with UL 1703, Table 1505.1. |

The PV module backsheet material could also help mitigate the damage of wildfires to PV systems. Researchers have experimented with backsheet thickness (ranging from thicknesses of 250-370 micrometers) and material type. Thicker backsheets typically have better fire resistance. Backsheets are typically made up of layers of materials such as fluoroethylene vinyl ether (FEVE), polyvinylidene fluoride (PVDF), polyethylene-vinyl acetate (PET), and polyvinyl fluoride (PVF). An experimental study on the Flammability of Photovoltaic Module Backsheets identified a PVF/PET/PVF three-layer backsheet as the top performer in fire tests, while a two-layer backsheet containing FEVE/PET was the most susceptible to burning.

| Recommendation: Choosing a module with a thicker backsheet (300 micrometers or thicker). A three-layer PVF/PET/PVF backsheet may provide more fire resistance than other backsheet compositions. |

The coloring of the semiconductor material in a PV module may increase the risk of fire in heavily vegetated areas with arid or semi-arid climates. Darker colored PV modules may be more susceptible to absorbing heat, which could raise the ambient temperature of the surrounding area. During exceptional and concurrent extreme heat and drought events, this can increase the risk of wildfire.

In general, during the module selection process, PV system planners may wish to opt for lighter-colored PV modules for systems in hot climates since the absorption of heat will lead to deficiencies in power generation, regardless of any potential impacts on wildfire occurrence.

System Considerations

The design of the PV system as a whole, rather than just the PV module alone, can also play a role in improving survivability of a PV system in an area prone to wildfires. Methods, such as vegetation management, protecting sensitive electronic equipment, fire suppression systems, and ease-of-access for firefighters can all reduce the risk of damage or destruction to a PV system during a wildfire.

Defensible space refers to the land area around a critical facility, like a PV system, that site owners manage in ways that reduce the possibility of a wildfire occurring there.

One of the most common ways of creating defensible space is reducing the amount of vegetation that could serve as fuel for a wildfire. The Federal Emergency Management Agency (FEMA) proposes that utilities create defensible space by paving the ground surrounding utility equipment with concrete to prevent the growth of any fuel that could increase fire risk.

This solution may work for a small-scale PV site where the costs of installing a concrete surface would be more affordable. This solution, however, could create other risks, such as an increase in flooding and runoff risk as well as increasing the heat in summertime operations, which could reduce the PV system's efficiency. Encasing the ground in concrete for large, utility scale sites is likely unfeasible.

| Recommendation: Follow FEMA or local fire code guidelines for maintaining a defensible perimeter. If vegetation growth is expected within this defensible perimeter, implement a regular O&M vegetation management plan. |

FEMA recommends that utilities place any sensitive infrastructure underground to reduce its risk of wildfire. Although this is not feasible for PV modules themselves, which need to have surface exposure to work effectively, PV owners may underground certain components of a PV system that are not the PV module itself, such as wire and conduits.

Undergrounding these components can be cost prohibitive, make their ongoing maintenance needs more complicated, and may increase the risk of other hazards, such as exposure to flooding. As a lower-cost alternative to a comprehensive undergrounding effort, PV owners may place sensitive wiring, cables, inverters, or energy storage systems inside of fire-resistant containers.

| Recommendation: Place electrical equipment such as inverters and batteries inside fire-resistant containers. Underground wire and conduit where practical. |

If vegetation management techniques are insufficient to reduce risk or the risk of wildfire is otherwise irreversibly high, the installation of an emergency fire suppression sprinkler system across the PV system might help deter the spread of fire from a wildfire on the outside of the PV site. By default, PV modules are waterproof and can survive exposure to water.

It is also important that firefighters can quickly access any part of the PV system that may be on fire or at risk of catching fire. By maintaining a minimum spacing distance between rows for ground-mounted PV systems, fire crews can more easily access fires that are burning in certain sections of the PV system.

Article 691.10 of the National Electrical Code specifies that PV systems without circuit interrupters must have a fire mitigation plan submitted with the local firefighting authorities, which must identify firefighting access within PV systems. Thus, PV system operators may decide on minimum spacing distances on a case-by-case basis in consultation with their local approving fire safety officials.

| Requirement: Follow local fire codes and consult with local fire department on setbacks and spacing to allow access. For sites with battery storage systems, engage local fire crews in fire suppression for the specific battery chemistry. |

The addition of a screen in front of or behind a PV system has demonstrated some degree of protection in establishing a minimum setback distance between any flames and the PV system. Installing a physical non-combustible barrier at the rear side of the PV module also has shown some success but may not be feasible for bifacial PV systems as the board blocks light from reaching cells on the underside of the PV module.

| Recommendation: Non-combustible screens or barriers can help prevent flames from spreading through a PV system, especially when installed at the rear side of modules. |

For roof-mounted PV, the spacing or distance between the underside of the PV module and the surface of the roof can influence the spread and behavior of flames that are burning adjacent to or directly burning the structure upon which the PV system is mounted.

Research by the Underwriters Laboratories has shown that Class A-rated PV systems mounted on Class A-rated, steep-angled rooves with a gap of approximately one foot are better able to resist the spread of flames in the space between the PV system and the roof relative to shallow-angled roofs.

Other research by the University of Edinburgh confirms this finding that an increase in gap height between roof-mounted PV modules and the top of the roof helps reduce the risk of the spread of flames.

Apart from the gap height, a steeper roof angle can generally reduce the risk of fire spread underneath a roof-mounted PV system. The addition of flashing to block the opening to this gap has also demonstrated partial success.

| Recommendation: If practical, install modules one foot above roof surface on sites at high risk for wildfire. |

Operations and Maintenance

The operators of PV systems should take preemptive actions in their management of their PV systems to avoid the physical and financial impacts of a wildfire event.

Reviewing their warranties and ensuring that fire risk plans are in place can help operators of PV systems avoid the high costs of a business-as-usual approach to operations.

In terms of physical measures, the removal of potential fuel for fires and the installation of power safety equipment can reduce the risk of wildfire and improve safety for first responders. If a fire has already occurred, techniques to assess the damage and clean surviving panels will help operators of the affected PV systems restore operations.

| Recommendation: Implement a regular O&M vegetation management plan. |

Conducting a fire risk assessment for a PV system in a known wildfire hazard area is critical for understanding and preparing for potential impacts of a wildfire and identifying methods to reduce the PV system's exposure to them.

The assessment should identify potential sources of ignition, identify the ways that any fires could spread across a site, and identify roles and responsibilities for emergency personnel responding to a fire at the site.

Recommendation: Conduct a risk assessment for PV system and form a wildfire emergency response plan.

Pre-Damage Techniques or Practices

Before a wildfire happens, operators of PV systems should ensure that any potential sources of fire ignition, like plant materials, are managed around the PV systems to create defensible space around the system. Installing an emergency power-down device for electrical circuits can help firefighters stay safe as they respond to a fire at a PV system so they can focus on neutralizing the fire source.

In the case of PV systems where the installation of hard paving is not feasible, system operators can opt for active vegetation management, via either human labor or through livestock grazing. The American Solar Grazing Association, for instance, provides guidance to PV system owners for contracting with shepherds to use livestock for curbing overgrowth of plants on sites with PV systems.

PV modules generate electricity if sunlight makes contact with the semi-conductor. They continuously produce live current that can be a danger to firefighters working to suppress a fire that has started near or spread to the PV system.

Since 2014, the National Electrical Code has required owners of all solar modules mounted on buildings to equip themselves with a "rapid shutdown" system.

While the rapid shutdown system will not de-energize the semi-conductor material itself, it will prevent electrical current from traveling along conduits and conductors and reduce the risk of electrocution to firefighters and the risk of electrical fire.

Not all states in the U.S. require the installation of a rapid shutdown system and the National Electrical Code allows ground-mounted systems to be exempt from having them.

Thus, PV system owners can take initiative by installing these systems themselves even though they may not be required.

Recommendation: Install and clearly label a rapid-shutdown system. Ensure local fire departments are trained on the use of the system and understand what will be energized and deenergized when the system is shut down.

Post-Damage Techniques or Practices

Post-damage techniques are currently limited as PV systems are generally destroyed if they are burned by a wildfire. Only a rebuild of the damaged sections of the PV system would likely restore the pre-wildfire operating conditions.

If the wildfire avoids burning the PV structures directly, it is still possible that the PV system received some degree of damage through the high air temperatures caused by the fires. Assessments of the potentially affected PV systems will show if any PV modules suffered damage.

Thermal imaging, with an infrared camera, for example, may indicate some damage that is not apparent after a wildfire. Any "hot spots" that thermal imaging shows should be evaluated with more precise imaging techniques or components with hot spots should be replaced.

PV systems' operators can use electroluminescence (EL) imaging to identify hidden damage on a PV module.

When a wildfire event passes near, though not necessarily through, a PV system, the high levels of heat from the fire can be severe enough to cause micro fissures or deformities in the PV cells, even if the PV system survives overall.

An EL imaging machine can reveal to field technicians working on recovery efforts where they might need to replace PV cells where fissuring has either reduced production efficiencies or completely destroyed the operability of the PV cells.

If wildfire does not directly damage the PV modules but they become covered in ash, then the PV system's owners need to remove the ash to restore optimal working efficiency. They can use automated methods or manual removal with workers.

Researchers have tested the use of robot cleaners that sweep particulate debris, particularly dust, off of PV systems with success. This method may apply to ash removal as well.

Manual removal of accumulated ash is preferable for system operators who have limited financial or technical capacity to implement expensive automated PV module-cleaning technologies. In these cases, ensure that tools used for ash removal will not damage the surface of the PV system.

To remove ash manually, use soap and water to remove ash but avoid using high-pressure hoses that can potentially damage the glass surface of the modules.Do not use cleaning products that are traditionally used for windows as they will increase the reflectivity of the PV modules' surface and reduce their efficiency.

Any conventional rags, towels, brooms, or other types of cleaning equipment that are not designed for cleaning PV modules will also increase the risk of damaging the PV modules.

Risk Profile

- Environmental Research Letters: Smoke from 2020 United States Wildfires Responsible for Substantial Solar Energy Forecast Errors

National Electric Code and International Building Code Designations

- ÜV SÜD Global Risk Consultants: Photovoltaic Rooftop Panels–Understanding the Risk of Fire

- IronRidge: Class A Fire Rating Technical Brief

Operations and Maintenance

- Firetrace International: Six Tips for an Effective Fire Risk Assessment

- Beny: What Is Solar Rapid Shutdown and Why Do You Need One for Your PV System?

- PV Tech: Rapid Shutdown for Solar Energy: What it Is and Why You Need It

- Solar Power World: Wildfire Season Is Here: What To Do if Your Solar Project Gets Scorched

- Proven Energy: Five Solar Panel Bushfire Care and Maintenance Tips

- Synergy Power: Cleaning Solar Panels During the California Wildfires

Contact FEMP for assistance with solar PV systems.