The U.S. Department of Energy’s Office of Fossil Energy and Carbon Management (FECM) is committed to helping the nation increase its domestic supply of these critical minerals and materials, which are essential to the way we live, to America’s economic..

Office of Fossil Energy and Carbon Management

February 6, 2024Critical minerals play a pivotal role in our everyday lives, used to develop components of modern technologies including smart phones and medical applications. Beyond these advancements, these minerals are crucial for the production of clean energy technologies that provide affordable, reliable energy while mitigating harmful emissions. The U.S. Department of Energy’s Office of Fossil Energy and Carbon Management (FECM) is steadfast in its commitment to bolstering the nation’s domestic supply of these critical minerals. This initiative is not only essential to the way we live, but fuels America’s economic growth, laying the foundation for a future where we achieve net-zero greenhouse gas emissions.

What are Critical Minerals and Materials?

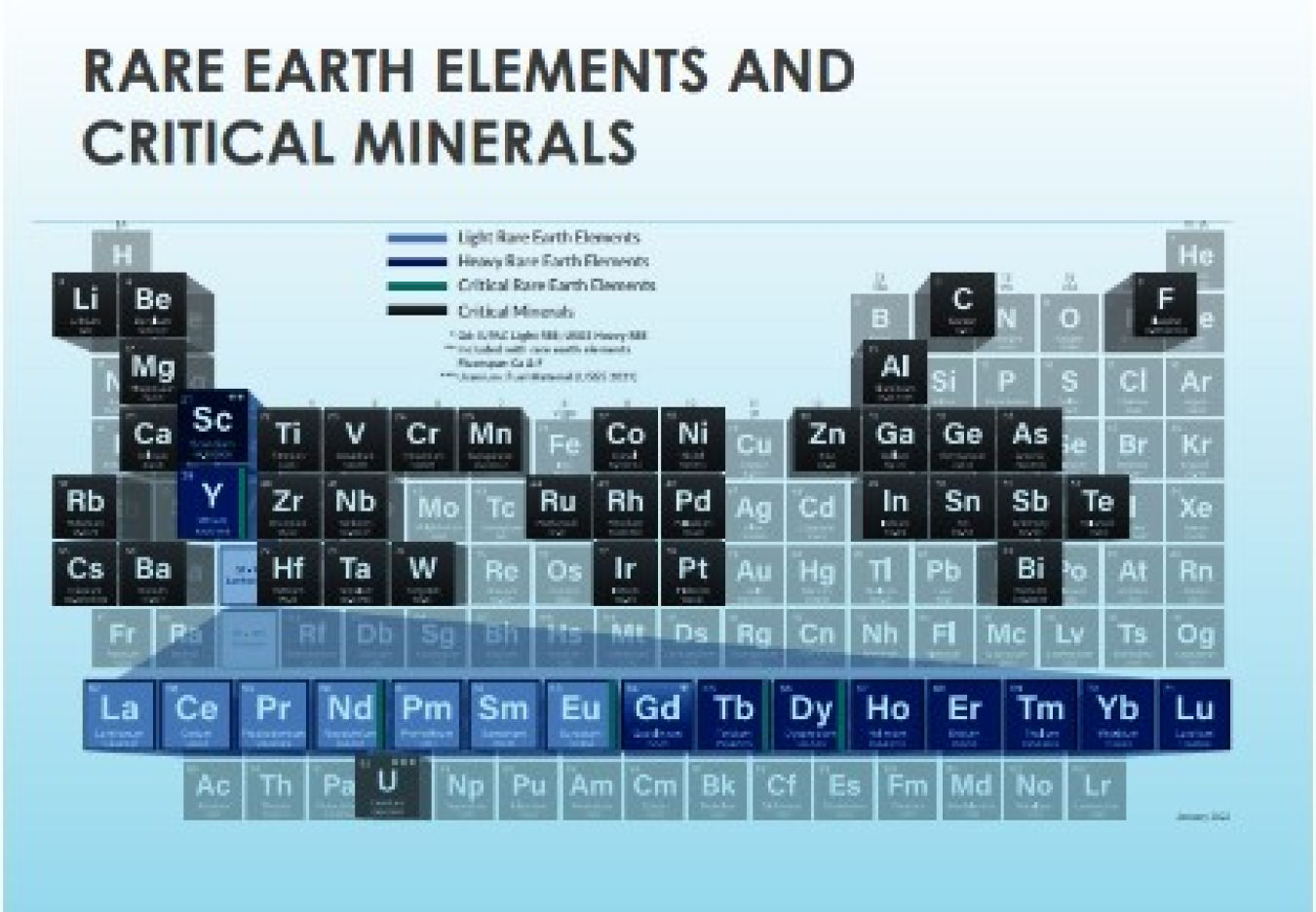

Critical minerals and materials are materials that are essential to the US economy, and whose supply chains have the potential to be disrupted. Rare earth elements—a subset of critical materials—are a group of elements distinguished by their distinctive magnetic, heat-resistant, and phosphorescent properties crucial in manufacturing products.

The U.S. Geological Survey has identified 50 critical minerals, including several commonly recognized elements such as aluminum, graphite, lithium, magnesium, and nickel. The DOE has identified 18 critical materials needed for future clean energy technologies, including 4 not on the USGS list—copper, silicon, silicon carbide, and electrical steel.

Why are Critical Minerals and Materials Important?

Critical minerals and materials are vital for a wide range of industries, including aerospace, health care, and defense. They are also key inputs to many clean energy technologies, including solar panels, wind turbines, electric vehicle batteries, and energy storage technologies.

As we work to advance toward a clean energy and industrial future, the need for critical minerals increases. Over 80% of our nation’s supply of critical minerals comes from foreign sources, and the United States currently imports over half of its consumption of 43 of the 50 critical minerals and metals. Notably, there’s no domestic production for at least 14 of these critical minerals. By developing a strong domestic supply of critical minerals, we will reduce our dependence on other countries, create high-wage American manufacturing jobs, and support communities across the country that have long depended on mining and energy production.

How is FECM Developing a Domestic Supply Chain of Critical Minerals and Materials?

As a part of our efforts to accelerate the domestic production of critical minerals, FECM’s Division of Minerals Sustainability is funding projects that will support the extraction, recovery, and refining of critical minerals and rare earth elements from unconventional and secondary sources, such as coal and coal byproducts, produced water from oil and gas production, coal-related waste streams (e.g., acid mine drainage), and other co-production streams from the extractive minerals industry.

Since January 2021, we have invested over $41 million in 26 critical minerals and materials projects across the United States. This includes the Carbon Ore, Rare Earth, and Critical Mineral initiative, which is made up of 13 place-based coalitions in traditionally coal-producing communities that will advance the recovery of rare earth elements and critical minerals from domestic basins.

Most recently, in April 2023, we selected projects in West Virginia and North Dakota to receive $16 million in federal funding from the Bipartisan Infrastructure Law to support the construction of America’s first-of-a kind critical minerals production facility. The project teams will develop cost estimates and schedules for the design, construction, and development of a demonstration facility to extract, separate, and refine rare earth elements and critical minerals from the nation’s vast quantities of mining wastes. When built, the facility will demonstrate how America can feed the growing demand for clean energy technology by repurposing and reusing mining wastes.

These investments, coupled with many other efforts across the Department of Energy, mark a step toward repositioning the United States as a leader in the responsible extraction and production of critical minerals.

Learn More

To learn more about how FECM is supporting the development of a domestic supply of critical minerals, sign up to receive email updates and follow us on Twitter, Facebook, and LinkedIn.