View this video about how laboratory technicians at the Hanford Site’s Waste Treatment and Immobilization Plant have been building proficiency in using a system that will safely transfer samples of radioactive waste.

Office of Environmental Management

March 22, 2022

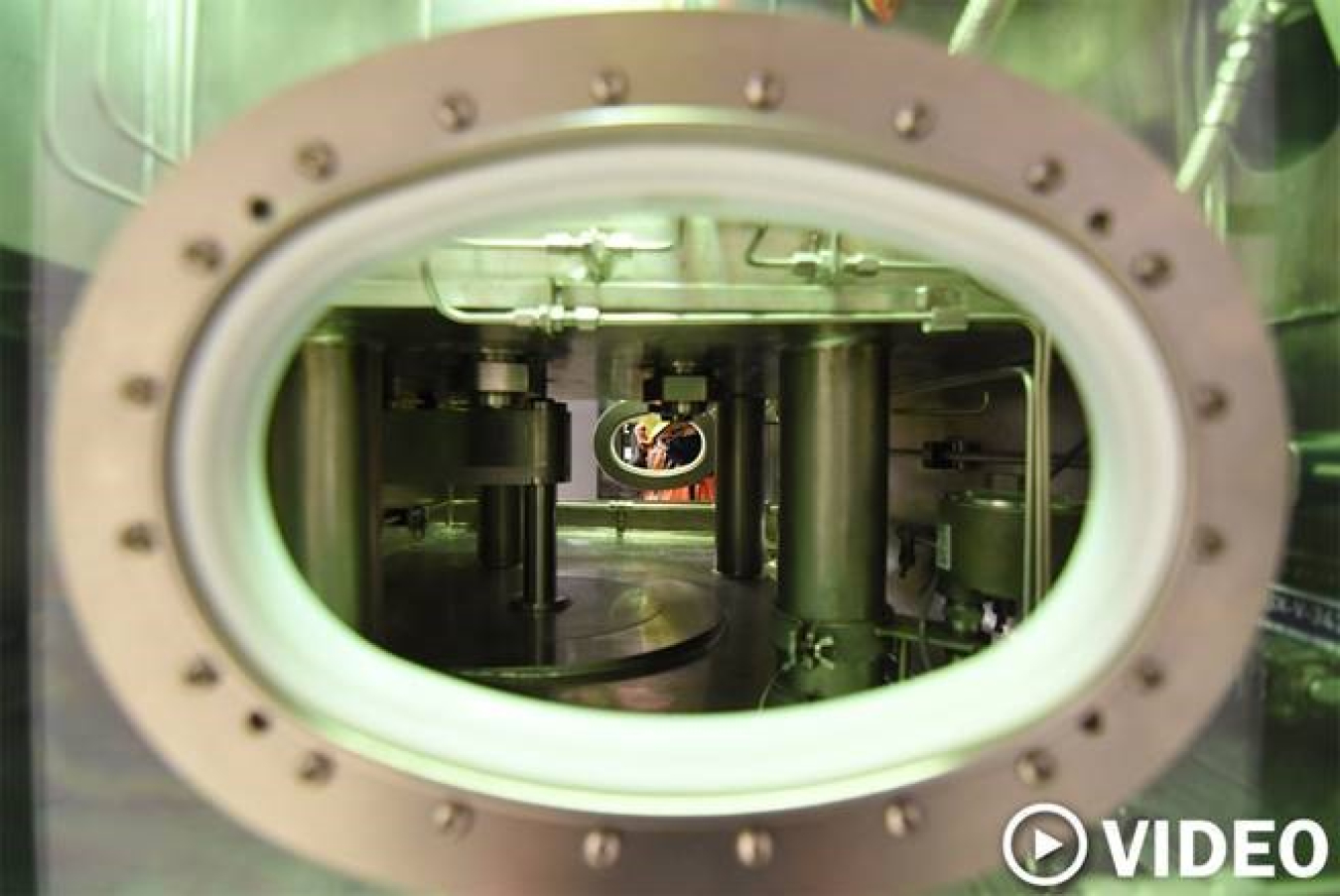

RICHLAND, Wash. – View this video about how laboratory technicians at the Hanford Site’s Waste Treatment and Immobilization Plant have been building proficiency in using a system that will safely transfer samples of radioactive waste from the Low-Activity Waste (LAW) Facility to the plant’s Analytical Laboratory for analysis. This autosampling system functions much like a pneumatic tube system at a bank drive-thru. Samples collected from LAW Facility process vessels are put into containers and transferred to the lab through a tube system by using pressurized air. During Direct-Feed Low-Activity Waste Program operations, plant chemists and technicians will analyze about 3,000 waste samples per year. Their analyses will confirm the correct “recipe” of glass-forming materials needed to mix with the waste during vitrification, or immobilization in glass, for safe disposal. This step ensures the plant produces a consistent glass form that meets all regulatory requirements and standards for disposal at Hanford’s Integrated Disposal Facility. Click here for the video of the testing.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.