Contractor teams recently collaborated to transfer 4,000 gallons of wastewater between two Hanford Site facilities.

Office of Environmental Management

September 3, 2024

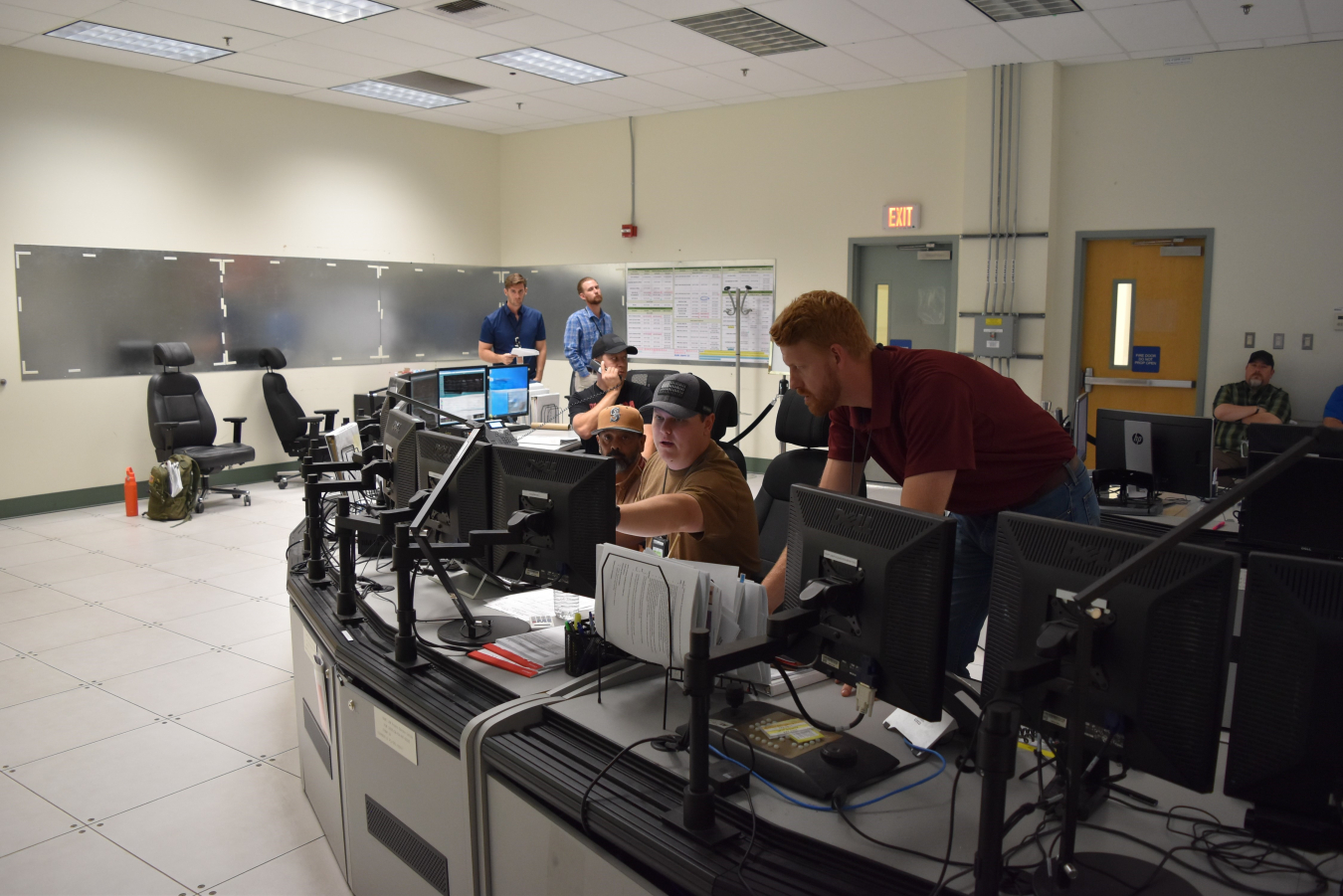

Workers observed and monitored equipment in the Waste Treatment and Immobilization Plant during commissioning of a transfer line for wastewater.

RICHLAND, Wash. – Contractor teams recently collaborated to transfer 4,000 gallons of wastewater between two Hanford Site facilities. They commissioned a transfer line that will support the site’s tank waste treatment mission. It’s another indicator contractors and facility operators are working as a team as they get ready for operations at the Waste Treatment and Immobilization Plant (WTP) to start next year.

The pipeline backs up the main one that will transfer wastewater from the Effluent Management Facility (EMF) at WTP to the nearby Liquid Effluent Retention Facility (LERF). The retention facility is made up of four large basins that store wastewater until it is treated to remove contaminants for disposal.

“As the site gets ready to immobilize tank waste in glass for safe disposal, integrated operations will continue to increase in frequency and complexity across multiple Hanford facilities,” said Delmar Noyes, Hanford assistant manager of Tank Waste Operations. “The contractors are demonstrating they can work together to complete the work safely and efficiently.”

Control room operators in the Hanford Site’s Effluent Treatment Facility, left, and Waste Treatment and Immobilization Plant, right, collaborate to commission a wastewater transfer line.

WTP contractor Bechtel National Inc. and tank operations contractor Washington River Protection Solutions (WRPS) practiced the steps required to commission the backup transfer line. To be successful, control room operators on both ends of the transfer line must keep lines of communication open to confirm the transfer is occurring.

“Testing our integrated systems as we use them for the first time means we will need to respond appropriately, conservatively and with a questioning attitude,” said Wes Bryan, WRPS president and project manager. “We demonstrated that the transfer system works, and the teams work effectively together.”

Bechtel Senior Vice President and WTP Project Director Brian Hartman echoed the importance of teamwork, saying, “As a One Hanford team, we are working together to integrate our activities as we advance toward treating tank waste.”

View this video to learn more about the EMF-to-LERF transfer.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.