Members of the Savannah River Site (SRS) workforce recently employed creative techniques to complete the vacuuming of spent nuclear fuel stored in an underwater basin to ensure continued processing of the fuel.

Office of Environmental Management

November 21, 2023

AIKEN, S.C. — Members of the Savannah River Site (SRS) workforce recently employed creative techniques to complete the vacuuming of spent nuclear fuel stored in an underwater basin to ensure continued processing of the fuel.

The fuel from foreign and domestic research reactors is safely stored in the L Area Disassembly Basin inside a former production reactor in the site’s L Area. The fuel is sent to the H Canyon at SRS for dissolution. Dissolution involves lowering the fuel into a nitric acid solution, which produces a liquid that is moved through the site’s liquid waste facilities to be vitrified, or made into glass, and safely stored onsite until a federal repository is identified.

L Area Operations Specialist Steve Osteen of Savannah River Nuclear Solutions (SRNS), the site’s managing and operating contractor, noted that a resin was deposited on a number of High Flux Isotope Reactor (HFIR) cores during L Area deionizer vessel operations in the early 1990s.

“The resin deposits rendered the cores unsuitable for dissolution and processing in H Canyon, which is the disposition path for this type of fuel,” Osteen said. “Our team had to come up with an innovative method for resin removal while the cores remained underwater to maintain adequate shielding from radiation.”

The resin is made up of tiny beads that trap radionuclides and help to remove radioactive ions from the basin water.

In 2020, a team of SRNS engineering, operations and construction employees partnered with scientists and engineers from the Savannah River National Laboratory to develop a methodology for removing the resin.

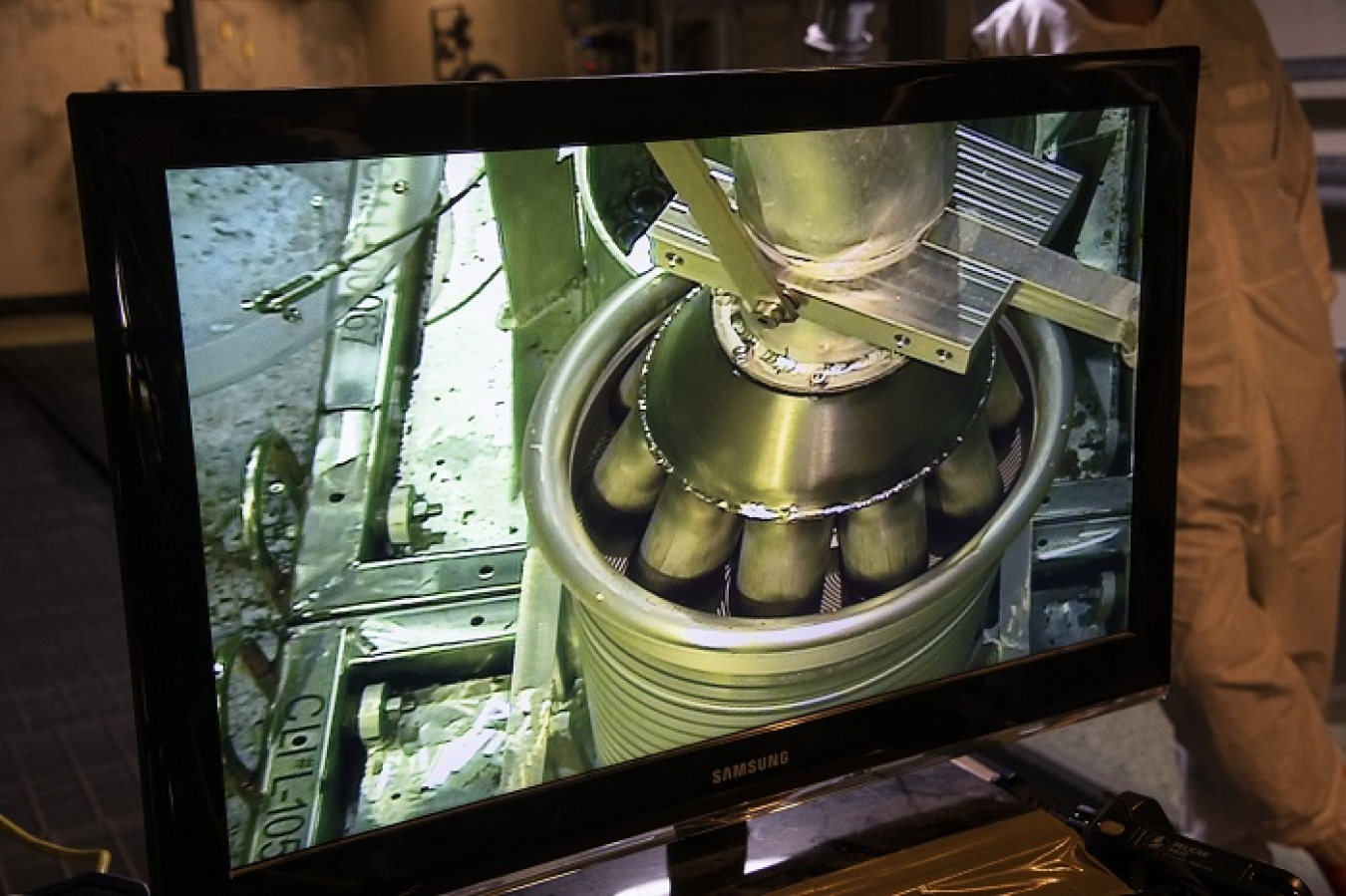

The team designed and installed an HFIR cleaning station and vacuum tool to be used with an existing basin vacuum system. HFIR cores were placed in the HFIR cleaning station, vacuumed and relocated, which allowed operators to vacuum the HFIR racks. By using this new process and associated tools, SRNS was able to recover 30 racks and add an additional 60 clean storage positions, and all HFIR cores have now been cleaned of resin.

“The ingenuity of this team in planning, designing and implementing new tools to allow for the vacuuming of the cores is commendable,” said L Area Facility Manager Neil McIntosh of SRNS. “The nearly three-year effort not only allows transfer to H Canyon of all HFIR cores currently stored in the basin but also allowed reclamation of all storage racks for future receipts.”

Now, the HFIR cores can be scheduled for dissolution and the basin can receive more cores without interrupting other operations.

“The ability of the SRNS team to always find a way to get the job done safely and efficiently is why they make a great workforce,” McIntosh said.

HFIR is the highest flux reactor-based source of neutrons for research in the U.S. using highly enriched uranium. The fuel elements, an inner and an outer element, together form a reactor “core.” The reactor is located at Oak Ridge National Laboratory in Tennessee.

To receive the latest news and updates about the Office of Environment Management, submit your e-mail address.