EM liquid waste contractor at the Savannah River Site are advancing a project to double-stack canisters containing high-level radioactive waste.

Office of Environmental Management

September 15, 2020AIKEN, S.C. – EM and its liquid waste contractor at the Savannah River Site (SRS) are advancing a project to double-stack canisters containing high-level radioactive sludge waste.

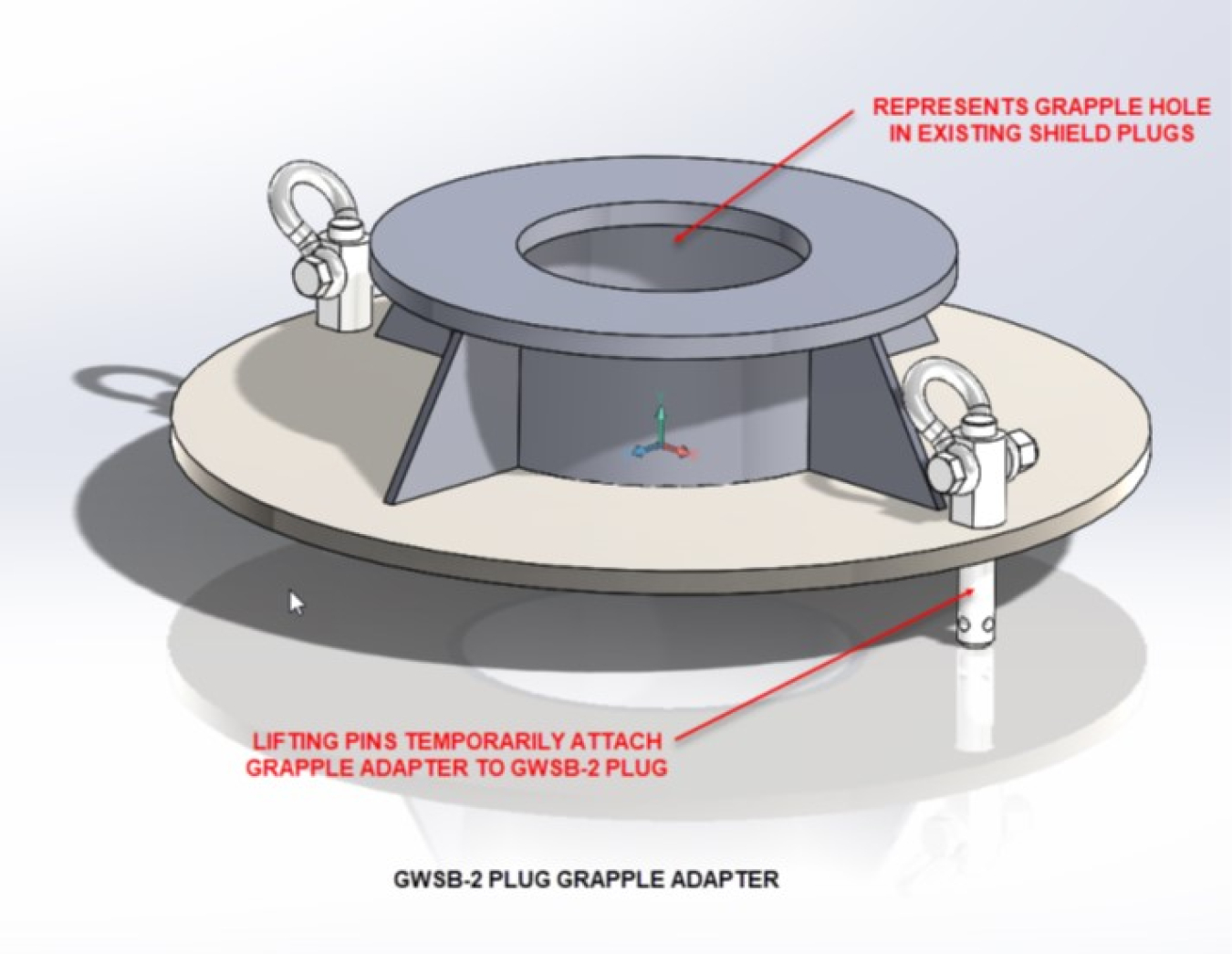

Savannah River Remediation (SRR) employees successfully demonstrated a newly designed adapter that will be used on the proposed plugs for double-stacking canisters in the Glass Waste Storage Building (GWSB) 2.

The canisters hold waste transferred from the SRS waste tanks and vitrified at the Defense Waste Processing Facility (DWPF). The filled stainless-steel canisters are safely stored in slots within a concrete and steel-reinforced underground vault inside the storage buildings adjacent to DWPF.

The canister double-stack project has been ongoing in the first storage building onsite, GWSB 1. Just over 1,000 canisters have been double stacked in GWSB 1 to date. The project will double the first building’s capacity from 2,262 to 4,524 positions.

Modifying the slots to store two canisters, one on top of the other, saves space and defers building an additional storage area, which could cost more than $100 million.

The demonstration of the grapple adapter is part of a feasibility study to determine if canisters can be double stacked in the second interim storage building, GWSB 2. The adapter is needed for the proposed GWSB 2 cast iron shield plugs due to the reduced height between the top of the shield plug and the upper canister in a GWSB 2 double-stack arrangement. The space normally occupied by the grapple cavity in the plug, below floor level, is needed for shielding; therefore, the grapple adapter was designed to be attached temporarily above the floor level of the shield plug before the plug is to be moved by the shielded canister transporter.

The one-of-a-kind transporter moves and double-stacks the canisters, and maneuvers the shield plugs. Using the transporter, operators successfully completed two cycles of simulated shield plug movement using the grapple adapter, proving it viable for use.

Jim Folk, DOE-Savannah River assistant manager for waste disposition, said the adapter demonstration is key to making progress in the canister double-stacking project.

“Optimizing canister storage space at the Savannah River Site is necessary to keep the liquid waste mission moving forward,” Folk said. “Processing will be accelerated with the Salt Waste Processing Facility coming online this year, so it’s important now more than ever to ensure we are adequately prepared for on-site interim storage solutions.”

SRR President and Project Manager Phil Breidenbach said advancing double-stacking capabilities inside GWSB 2 will improve the interim storage efficiency.

“I am proud of the DWPF teams who pulled their efforts together to prove the success of the new grapple adapter,” Breidenbach said.

The feasibility study for double-stacking canisters in GWSB 2 has also included safety basis, radiological, fire protection, structural, environment, and other technical evaluations. The next step will be to conduct a demonstration of double-stacking two canisters in GWSB 2, which is anticipated for summer 2021.

Additional storage areas will not have to be built if the canisters in GWSB 2 are double stacked. The canisters will be safely stored in the GWSBs until a federal repository for high-level waste is established.