Workers with the EM Richland Operations Office contractor Central Plateau Cleanup Company recently finished extensive modifications at the Hanford Site's Waste Encapsulation and Storage Facility.

Office of Environmental Management

September 5, 2023

RICHLAND, Wash. – Workers with EM Richland Operations Office contractor Central Plateau Cleanup Company (CPCCo) recently finished extensive modifications at the Hanford Site’s Waste Encapsulation and Storage Facility (WESF), a significant step in preparations to move 1,936 radioactive capsules of cesium and strontium from the facility’s water-filled basin into dry storage casks starting in 2025.

The stainless steel capsules are generally 21 inches long and 2 ½ inches in diameter and are stored under 13 feet of water that provides shielding from radiation and keeps the capsules from overheating.

The next significant step will be installing equipment for moving the capsules from the underwater basin into dry-storage casks, and then moving the dry-storage casks to a nearby concrete pad that will provide safe and compliant storage until a final disposition path is determined.

“While the capsules are safely stored in the basin, moving them to dry storage eliminates a long-term risk in the unlikely event of a larger-than-expected earthquake causing water to leak from the basin,” said Gary Pyles, EM federal project director at Hanford. “Moving the capsules out of the aging facility will reduce storage operating costs by an estimated $6 million per year and pave the way for eventual decommissioning and demolition of the facility.”

Most of the modifications were made in three areas of the facility where capsule transfer equipment will be installed — a shielded hot cell, an operating “canyon” and a truck loading area.

“The construction crews have done an excellent job preparing the nearly 50-year-old storage facility for its new mission,” said Neal Sullivan, who manages the modification and capsule removal projects for CPCCo. “They’ve spent the past two years removing interferences and either modifying, relocating or installing wiring, piping and other components to support installation of the various process systems.”

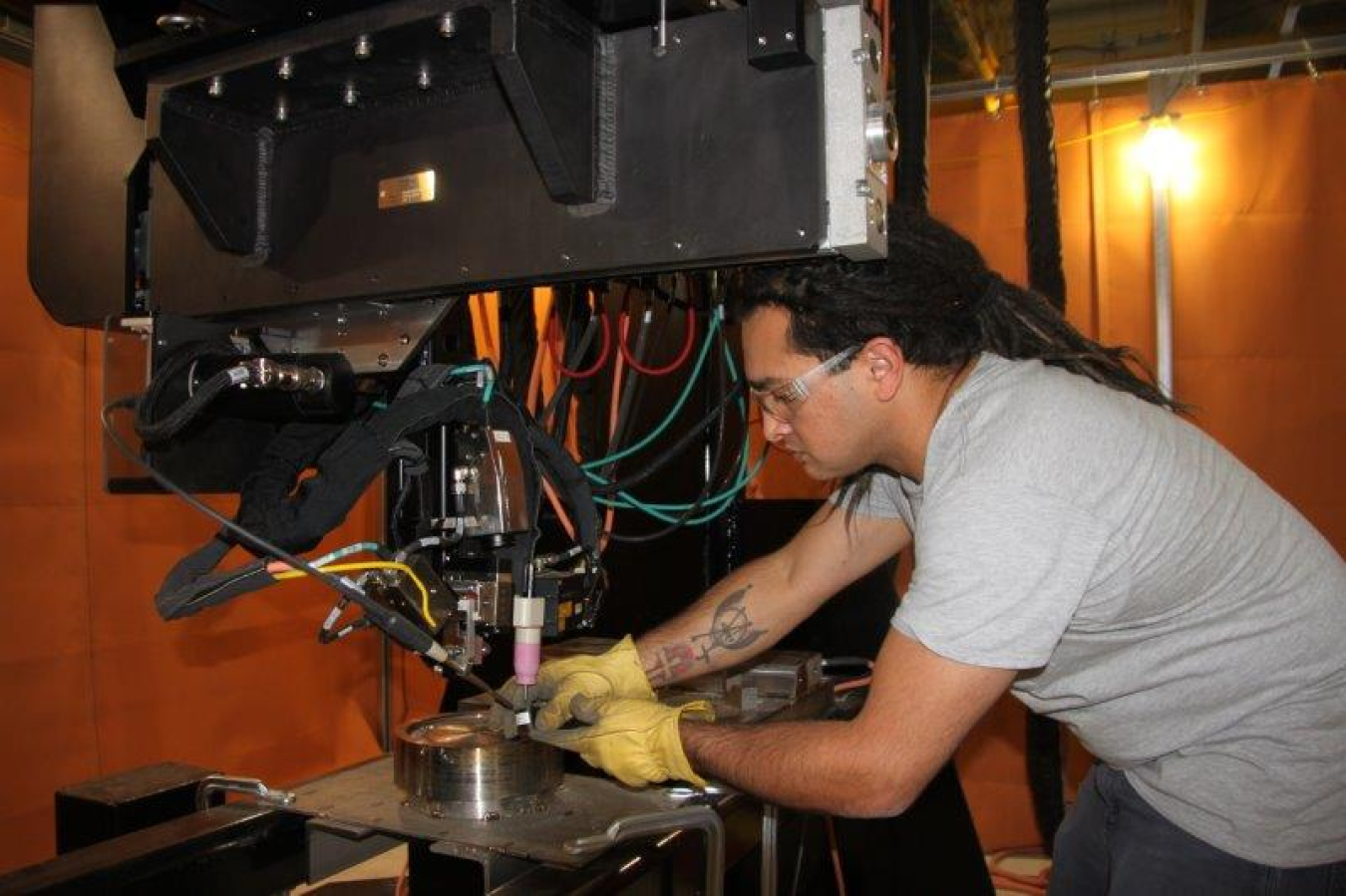

Meanwhile, at an on-site mock-up facility about 15 miles from WESF, CPCCo engineers and technicians began testing the capsule transfer equipment.

The mock-up contains replicas of the WESF hot cell, operating canyon and truck loading area, and helps workers train on using the capsule transfer equipment in a non-hazardous facility before starting operations at WESF.

-Contributor: Mark McKenna

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.