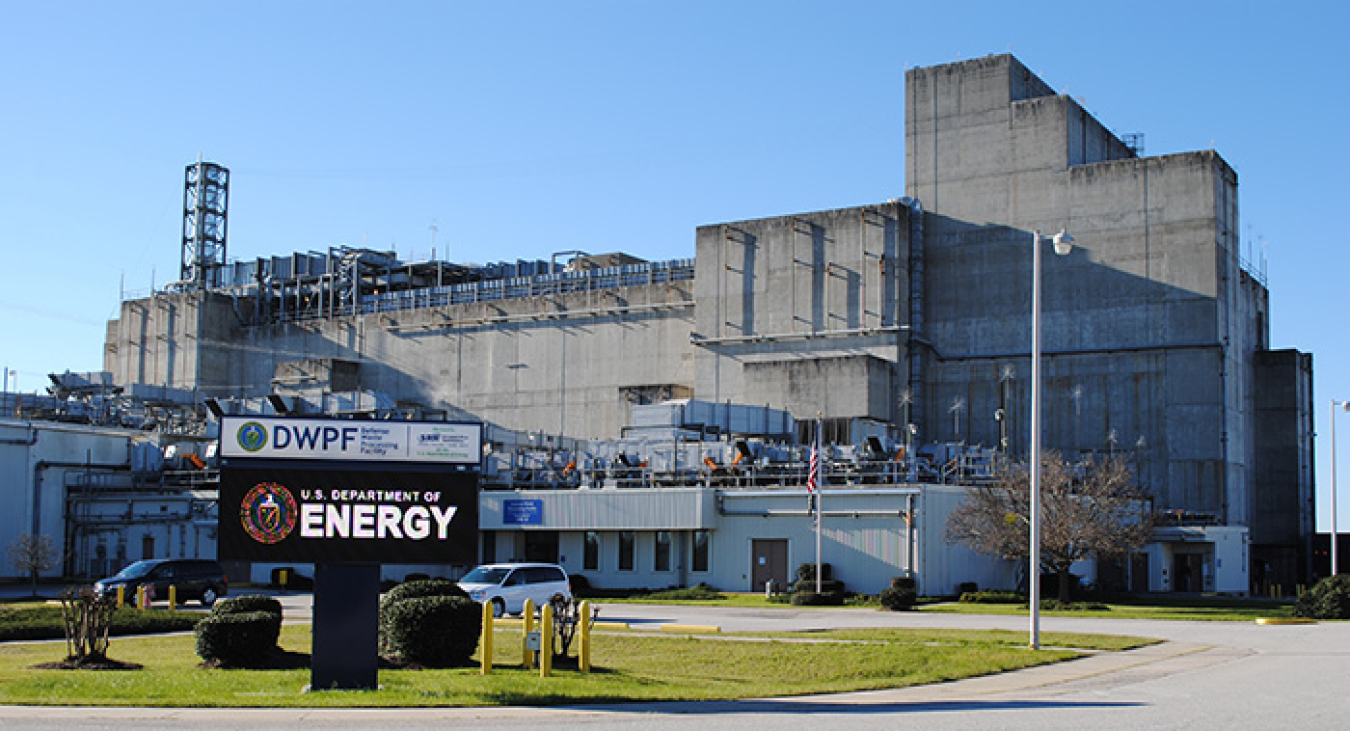

The Defense Waste Processing Facility at the Savannah River Site, operated by Savannah River Remediation.

Office of Environmental Management

September 12, 2019

AIKEN, S.C. – For 23 years, EM at the Savannah River Site (SRS) has been using the nation’s only operating vitrification plant to help reduce the single greatest environmental risk to South Carolina.

The Defense Waste Processing Facility (DWPF) has vitrified, or glassified, just over 4,200 canisters of high-level radioactive sludge waste. About 35 million gallons of radioactive waste, part of the byproduct of Cold War nuclear weapons production and considered by state regulators to be the state’s greatest environmental risk, are safely stored in waste tanks at SRS.

The high-level waste stream is sent to DWPF to be processed through the “heart” of the facility, a key vessel known as the melter. Inside the melter, the waste is mixed with a borosilicate glass, or frit, and heated until molten, then poured into stainless steel canisters to harden. The facility is projected to produce about 8,121 canisters, according to the SRS liquid waste system plan.

The canisters are kept safely in interim storage — underground lead-lined vaults in two buildings adjacent to DWPF, destined for a future federal repository.

Immobilizing the waste in a solid form reduces the risks associated with the continued storage of the liquid waste and prepares it for final disposal.

More than 16 million pounds of glass have been produced through DWPF over the last two decades.

Currently operated by Savannah River Remediation (SRR), the site’s liquid waste contractor, DWPF has also assisted in the closure of high-level waste tanks at SRS. Eight of the 51 tanks at SRS have been operationally closed — emptied, cleaned, and filled with a specially formulated grout.

DWPF will continue to immobilize the liquid waste and aid in tank closure, further reducing risk to workers, the community, and the environment.

Click here for more information on the Savannah River Site.