The Testing Expertise and Access for Marine Energy Research program brings together experts to support the development of marine energy technologies. Learn about one developer’s work with the program to test a new component of its wave energy converter.

Water Power Technologies Office

April 13, 2023The United States has an abundance of marine energy resources. In fact, there is enough potential marine energy in U.S. waters to meet nearly 60% of the country’s annual power demand. Even if only a small portion of that potential is captured, marine energy could play a big role in achieving U.S. net-zero-emissions goals. Yet developing and bringing new technologies to market that harness the power in waves, tides, and river and ocean currents can be a long, winding road.

That’s why the Testing Expertise and Access for Marine Energy Research (TEAMER) program—sponsored by the U.S. Department of Energy’s (DOE) Water Power Technologies Office (WPTO) and directed by the Pacific Ocean Energy Trust—brings together experts to support the development of new marine energy technologies.

The TEAMER program gives developers the opportunity to partner with academic institutions and national and private research laboratories to test and refine new marine energy devices as they prepare for commercialization. Developers are paired with technical experts at the nation’s leading research facilities for customized testing and technical support.

“TEAMER helps make an important link between developers and national laboratories, which offer expertise and world-class testing facilities,” said Tim Ramsey, WPTO’s Marine Energy Program Manager. “This teamwork can help hone new marine energy technologies as they work to reach the commercial market.”

That’s why marine energy developer, Triton Systems, Inc. (Triton) was eager to test a new component of its wave energy converter (WEC) through the TEAMER program. Triton had recently incorporated new design features to minimize the effects of biofouling on its WEC. Preventing biofouling—the natural accumulation of plants and animals on devices in water—is key to ensuring devices’ longevity. Partnered with scientists at Pacific Northwest National Laboratory (PNNL), Triton experts wanted to evaluate their new design and assess how efficiently it converted wave energy into power.

“The TEAMER program has allowed Triton to conduct additional testing and risk mitigation activities outside the scope of our DOE research grants. We requested to work with PNNL specifically due to their expertise in marine renewable energy and the unique capabilities of their Sequim facility,” said Tyler Robertson, mechanical project engineer at Triton Systems. “Their investigations have led to direct improvements in our WEC system. This saved us significant time and money, as it enabled us to make more technical progress instead of spending that time troubleshooting.”

A Marine Energy Dream Team

To evaluate the new anti-biofouling design, Triton needed to set up controlled experiments in a research facility with access to natural seawater. Natural seawater is key because it contains the microscopic plants and animals that cause biofouling—attributes missing from artificial saltwater.

“PNNL was a perfect fit for Triton's test objectives because the PNNL-Sequim lab is the only facility in the TEAMER network that provides access to raw, flow-through seawater,” said Nikki Sather, PNNL program manager for TEAMER projects.

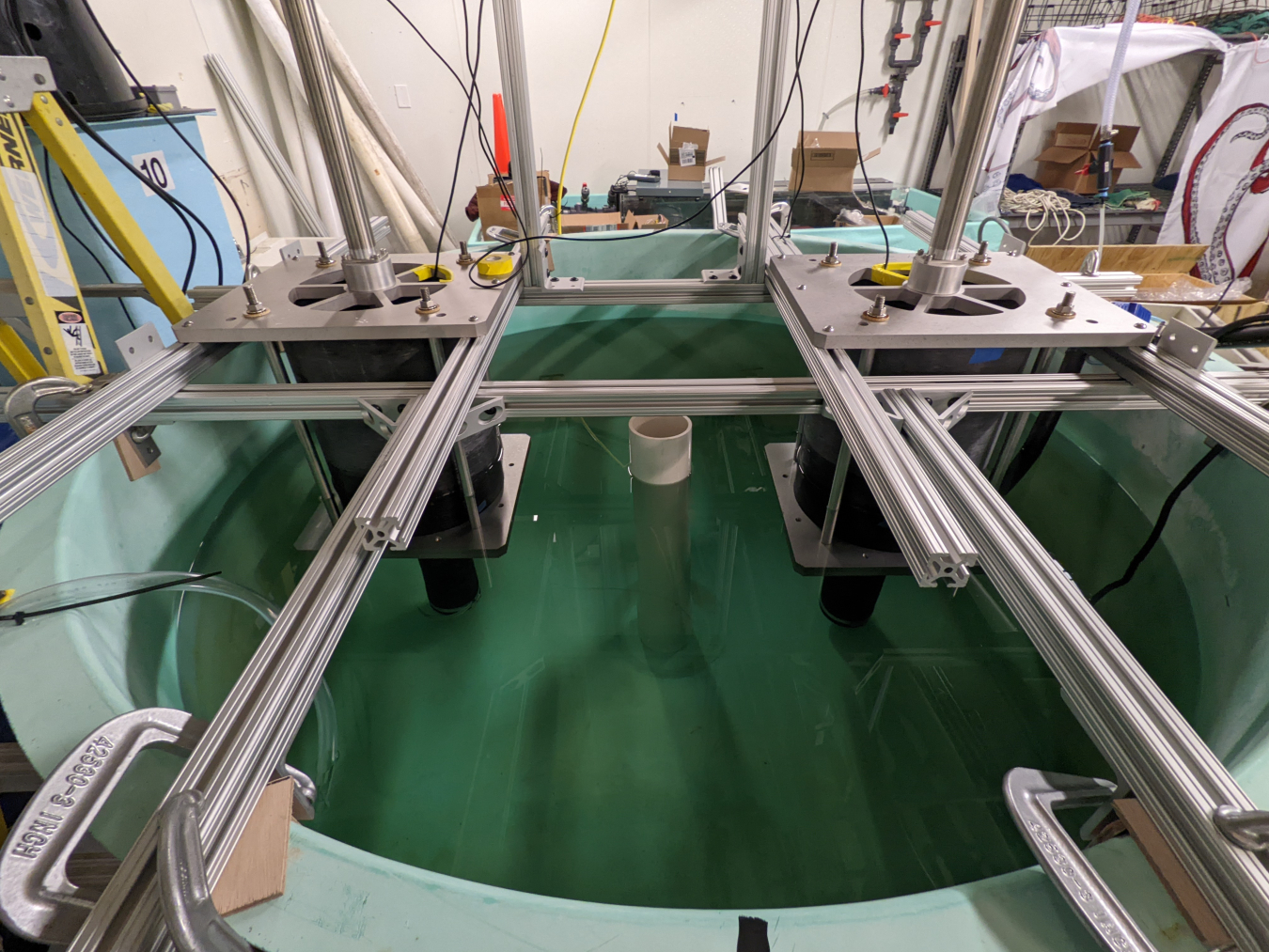

Using indoor tanks that continually cycle natural seawater pumped from Sequim Bay just a few hundred yards away, PNNL’s team of marine researchers and ocean engineers helped Triton set up a controlled test to evaluate the effects of biofouling on its device, along with additional monitoring to enhance the experiment and provide useful information to Triton.

“While we were scoping out the experimental design with Triton, our team recognized that additional measurements would be needed to help Triton fully evaluate the device performance and really address their test objectives—like measuring force to evaluate friction and power generation and monitoring water quality,” explained Robert Cavagnaro, principal investigator on the project. “These measurements went beyond what’s considered standard to assess biofouling.”

More Force but Less Power

Right from the start, it was clear that testing in natural seawater would provide valuable and unexpected information that would help Triton hone its design. Within just a few weeks of starting the experiment, PNNL researchers noticed the amount of force generated by pistons in the device was much higher than expected. The pistons are components in the system that convert wave energy to electrical power. More force required to move the pistons is the result of more friction and less efficient power generation—a sign that the device was not functioning as intended. So, the PNNL team started investigating.

“We took the device apart to get a closer look,” explained Linnea Weicht, PNNL mechanical engineer. “One of the composite bands inside the device was corroding, creating friction, and leading to more force than expected.”

The composite bands help the pistons to move smoothly and reduce friction, so corrosion there would interfere with device performance. It turned out that particular band underwent accelerated corrosion because it had a different metal powder additive than other components in the device. This came as a surprise to everyone, including Triton, which had not intended for that metal to be in its device. If the WEC had been deployed at sea with this particular band, corrosion would have quickly hampered device performance and required time-consuming and costly retrieval and repair. However, since PNNL researchers were monitoring the device during controlled testing in natural seawater, they were able to diagnose the unexpected issue quickly, saving Triton time and money.

Real Seawater Yields Real Results

From March to July 2022, a growing season for many marine fouling organisms, PNNL researchers monitored the performance of the Triton WEC. They started to notice a pattern: every day the force within the device would peak in the afternoon. The pattern also seemed to change with the seasons. The team had a hunch they knew what was causing it.

“We monitor the water temperature in Sequim Bay where we pump in seawater for experiments and quickly realized that the changes in seawater temperature throughout the day mirrored the changes in force in the device,” said Cavagnaro.

To test this hypothesis, the researchers added a sensor inside the tank to monitor changes in water temperature. The data confirmed that the amount of force inside the device went up as the seawater temperature naturally increased throughout the day.

“Materials are affected by temperature differently. When the temperature rises, some materials expand more than others,” explained Weicht. “The device’s pistons and the cylinders they sit in were made of different materials and reacted to the water temperature changes at different rates. The material of the piston expanded more than the material of the cylinder as the temperature rose, creating more friction and force inside the device.”

Marine Energy Takes a TEAMER

As is common in research and development endeavors, the final results were surprising: over the four months of testing, the WEC performance was more affected by environmental changes, like seawater temperature fluctuations, than biofouling. The device faced variations in temperature and an algal bloom in Sequim Bay that occurred during the experiment. Testing the device in these natural seawater conditions revealed valuable information about its performance. In addition to the unique facilities, the multidisciplinary team and strong collaboration yielded more information than initially expected.

“Thanks to the thorough investigation by the researchers at PNNL, Triton was able to replace that corroding component before it put both wave tank and open-water tests at risk,” said Robertson. “Triton used these results to select materials that were more compatible with seawater and develop new designs for pistons and seals that can adapt to changing seasons and temperatures.”

Interested in partnering with marine experts at world-class facilities to hone and develop your marine energy device? Apply now for technical support through the TEAMER program.

Stay in the know with WPTO! Receive the latest information on funding opportunities, events, and other news by subscribing to the bimonthly The Water Column newsletter, as well as the comprehensive, monthly Water Wire newsletter.