SUBSCRIBE to the Fact of the Week

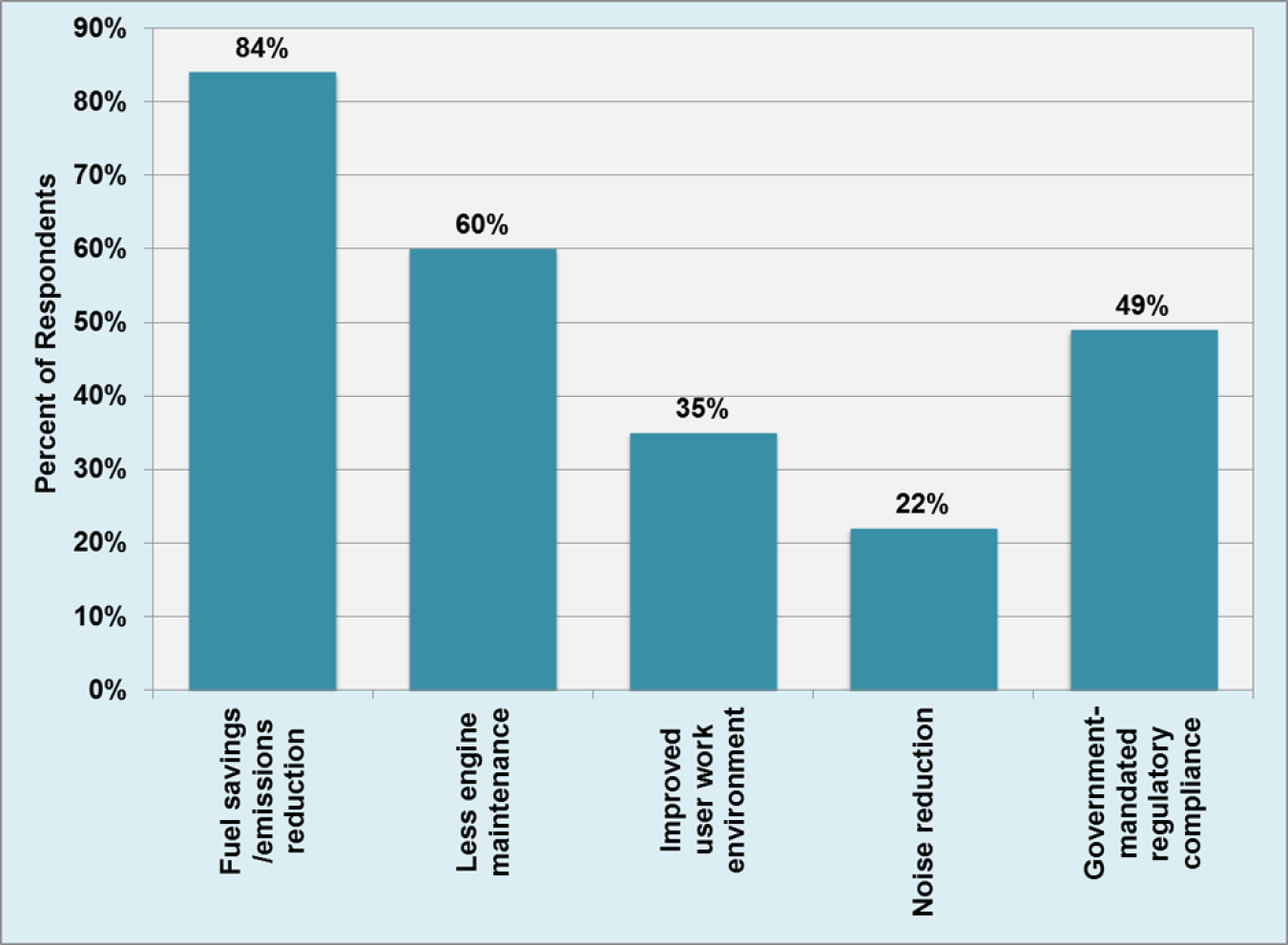

The 2015 Work Truck Electrification and Idle Management Study surveyed fleet owners operating throughout the United States with fleet sizes ranging from less than 10 trucks to fleets with more than 5,000 trucks. Fleets included government, utility, delivery, cartage, construction and others. Those fleet managers that adopted idle reduction technologies were asked what their business reasons were for implementing those technologies. Eighty-four percent cited fuel savings/emissions reduction followed by reduced engine maintenance at 60% (multiple answers were permitted from the survey respondents). Meeting government regulatory compliance was the third most cited reason while improved work environment and noise reduction were also common reasons for adopting idle reduction technologies.

Business Reasons for Idle Reduction, 2015

Notes:

- Totals do not equal 100% because respondents could select multiple answers.

- Technologies used for engine-off operation are primarily battery pack systems, but also include generator packages/auxiliary power units and field-based grid tie-in systems. These systems provide power for cab heating and cooling, powering lifts, welding equipment, power tools, laptops and other equipment while the main truck engine is shut down.

Supporting Information

| Business Reasons for Idle Reduction | Percent of Respondents |

|---|---|

| Fuel savings/emissions reduction | 84% |

| Less engine maintenance | 60% |

| Improved user work environment | 35% |

| Noise reduction | 22% |

| Government-mandated regulatory compliance | 49% |

| Not applicable | 10% |

| Other | 4% |

Source: | |