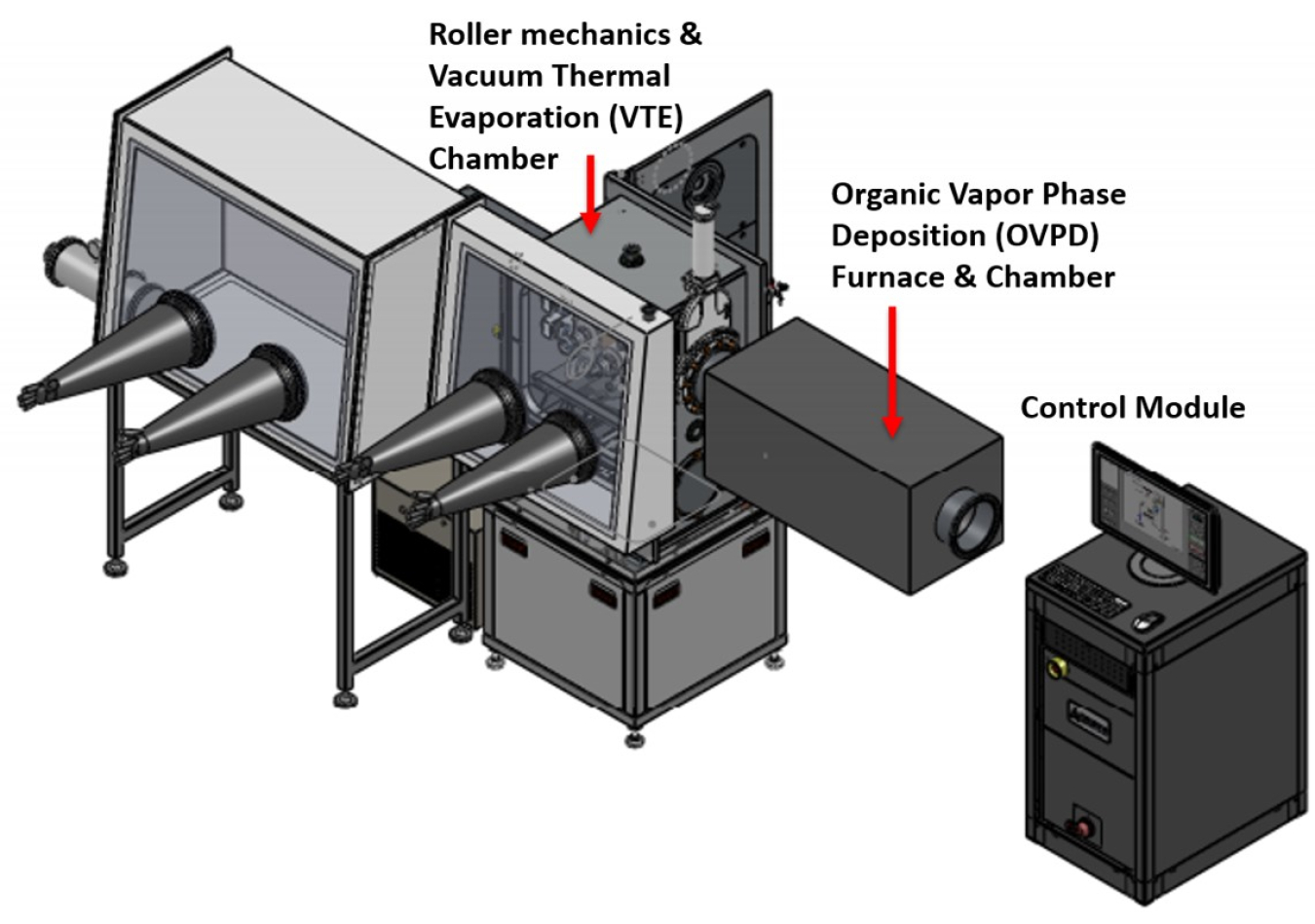

Illustration of laboratory roll-to-roll system used for producing OLEDs via interconnected OVPD and VTE systems.

Researchers at the University of Michigan are teaming up with OLED manufacturer Universal Display Corp. (UDC) to develop a low-cost roll-to-roll (R2R) process for the manufacturing of flexible OLED devices to be used in general illumination. Currently, white OLEDs—which are used for general illumination—are primarily batch-produced on relatively thick, brittle glass substrates, with limited throughput and at high cost. The R2R process being developed will produce, at high speed and reduced cost, a continuous output of encapsulated flexible, lightweight OLED lighting fixtures at a projected cost of <$10/klm.

The researchers will demonstrate reliable, encapsulated 25 cm2 flexible white OLED panels with an efficacy of 50 lm/W and a CRI >85 on barrier-coated plastic films or thin glass produced in a single, integrated system. The R2R process developed by the researchers has the capability to reduce the cost of commercial lighting by more than tenfold. It deposits the active layers of the OLED by organic vapor phase deposition (OVPD), a process invented by the researchers in 1995. OVPD uses a hot, inert carrier gas to transport organic materials to a cooled substrate, thus controlling the deposition rate by both the gas flow and the temperature. This allows for high materials utilization, precise doping, and high deposition rates.

To achieve high throughput for cost reductions, the team has developed a theory for understanding gas phase nucleation and void/cluster formation at high growth rates. The researchers are using OVPD to produce uniform thin films with smooth surfaces at a rate of up to 5 nm/s. Together with UDC, they will prepare a market forecast for OLED lighting, a cost model, and a commercialization roadmap for launching and licensing this R2R manufacturing technology. The results of the project are expected to stimulate interest in the licensing of the developed R2R tool and processes, thereby giving a substantial boost to OLED manufacturing in the U.S. (September 2020)

Return to Research Highlights.