Project Name: Desalination by Membrane Distillation Using Ceramic Membranes

Funding Opportunity: Solar Desalination

SETO Subprogram: Concentrating Solar Power

Location: Storrs, CT

SETO Award Amount: $873,648

Awardee Cost Share: $218,926

Principal Investigator: Jeffrey McCutcheon

APPROACH

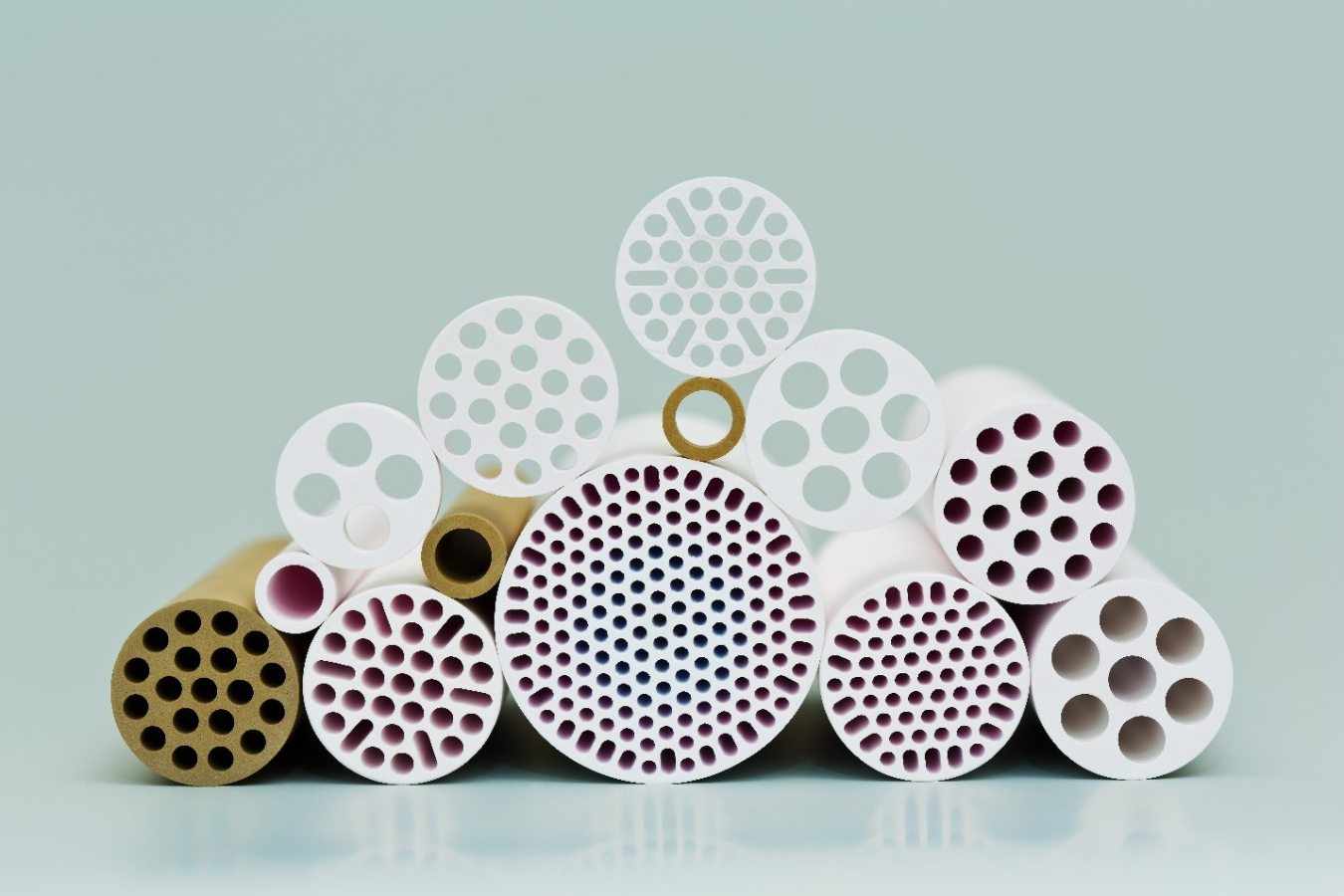

The team will develop a stronger ceramic membrane that can tolerate the passage of water vapor in a high temperature, chemically abrasive MD environment. The approach will later be adapted to include more complex membrane shapes with greater surface areas to allow more water vapor to pass through, thereby increasing efficiency. The team will model the performance of these geometries, verify the accuracy of the model, and then calculate a price per cubic meter for the water used in the ceramic membrane MD process.

INNOVATIONS

Ceramic membranes can be expensive and are not typically used for MD. But their cost has come down recently, due to the development of membranes with new, unique shapes that can pack more surface area into smaller volumes. These membranes can also last a lot longer than conventional membranes do in extremely hot saltwater environments that require MD for treatment or water removal. The reduced cost of the membranes combined with longer lifetimes could help reduce the cost of desalination.