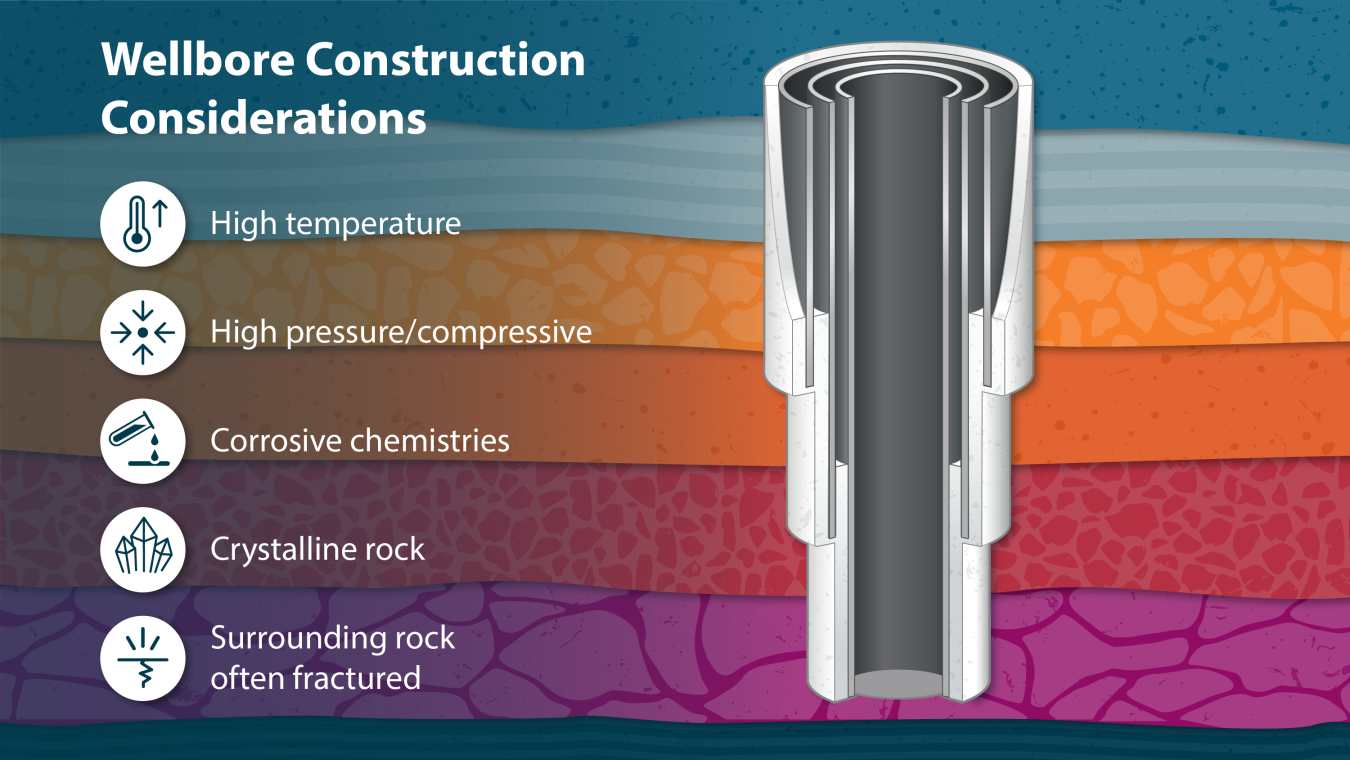

Wellbores are a critical component of the infrastructure and success of geothermal electricity generation projects and represent a significant investment for developers. Improving the durability and costs of wellbore structures and ensuring long-term well flow are vital to reduce costs and ensure safe, efficient operation of geothermal power plants. The Geothermal Technologies Office (GTO) is investing in projects to that can support these needs for both next-generation and conventional geothermal systems. By improving ways to build, assess, and maintain geothermal wellbores, these projects will expand opportunities to tap firm, flexible, domestic geothermal energy nationwide.

GTO convened Oak Ridge National Laboratory, Brookhaven National Laboratory, and Sandia National Laboratories as well as 35 experts from industry and academia to develop a Technology Roadmap for Advanced Geothermal Well Construction. The roadmap shares priorities for research and development in the following areas:

- High-performance and cost-effective materials for target geothermal well conditions

- Well construction methods and techniques to reduce construction costs

- Methods and techniques to decrease long-term operating costs

It also provides actionable plans for reducing the life cycle cost of geothermal wells and sets targets for the next 10-year period.

The results from the working group informed development of a GTO initiative to support wellbore construction and evaluation. The available off-the-shelf solutions for well cement and casing evaluation are suitable for the upper end of the oil and gas industry’s temperature needs, but are not generally considered adequate for hotter geothermal systems. To address this gap, GTO is funding five projects to address downhole cement and casing evaluation tools for use in high-temperature and hostile geothermal wellbores.

The projects and their research goals are:

- Clemson University (Clemson, SC): AI-enabled, photoacoustic imaging tool for high-temperature and high-pressure well logging to assess geothermal well integrity without active cooling.

- Innovative Downhole Solutions, Inc. (Houston, TX): Durable ultrasonic measurement tool capable of operating for 24 hours in high-temperature geothermal environments to assess wellbore construction materials and practices.

- Lawrence Berkeley National Laboratory (Berkeley, CA): Tool for geothermal borehole integrity evaluation, designed to assess wellbore integrity in extreme conditions without the need for downhole electronics.

- Los Alamos National Laboratory (Los Alamos, NM): High-resolution acoustics-based tool to provide high-fidelity data for evaluating EGS components under extreme conditions.

- Schlumberger Technology Corporation (Houston, TX): Wireline tractor-conveyed system for long-term integrity modeling of cement and casing.

In wells, loss zones occur when a well loses circulation of fluids to a low-pressure, permeable formation somewhere in the well. Lawrence Berkley National Laboratory’s GTO-funded project to improve lost circulation management (LCM) for geothermal is developing an improved LCM approach for different loss zone conditions to avoid having to rely solely on the operator’s experience to mitigate issues. After reviewing current practices guiding use of LCM, the team developed case studies for LCM use in different loss zone types and conducted extensive laboratory investigation of selected LCMs to identify their mechanical, physical, and sealing properties at temperatures relevant for geothermal wells. Laboratory results have been evaluated via a field test in a geothermal well and the project is close to completion. The improved LCM approach for drilling geothermal wells will help mitigate adverse conditions while drilling and significantly reduce non-drilling times resulting from lost circulation problems.

Wellbore construction and evaluation work is part of GTO’s enhanced geothermal systems (EGS) program. Learn more about GTO's EGS Research and other GTO initiatives.