In 2018, a team at the National Renewable Energy Laboratory designed and built the CWC's second-generation wind tunnel.

March 6, 2019The Collegiate Wind Competition (CWC) has used wind tunnels since its inception in 2014 to test the capabilities, including performance and durability, of student-designed wind turbines. A wind tunnel is a hollow tube with a powerful fan at one end that creates air flow inside the tunnel. Wind tunnels help engineers and manufacturers design, create, and build faster, safer, more reliable, and more efficient products of all kinds—like wind turbines.

In 2018, a team of engineers, technicians, and machinists at the National Renewable Energy Laboratory (NREL), designed and built the CWC's second-generation (Gen2) wind tunnel. This team worked together on the overall design of the tunnel, and Lee Jay Fingersh handled the performance while Jason Roadman and Heidi Tinnesand worked on the structural and mechanical design together. Other crucial aspects were handled by Don Baker, Troy Boro, Bill Gage, Rob Goldhor, Jerry Hur, Dave Jager, Garth Johnson, Mark Murphy, Simon Thao, Sara Wallen, and Scott Wilde, including tunnel fabrication, assembly, wiring, and instrumentation.

The first-generation wind tunnels were proof-of-concept models intended for use only as the competition was getting established, and Roadman had prior experience with wind tunnels during his studies at both Virginia Tech and the University of Colorado at Boulder, so he led the project.

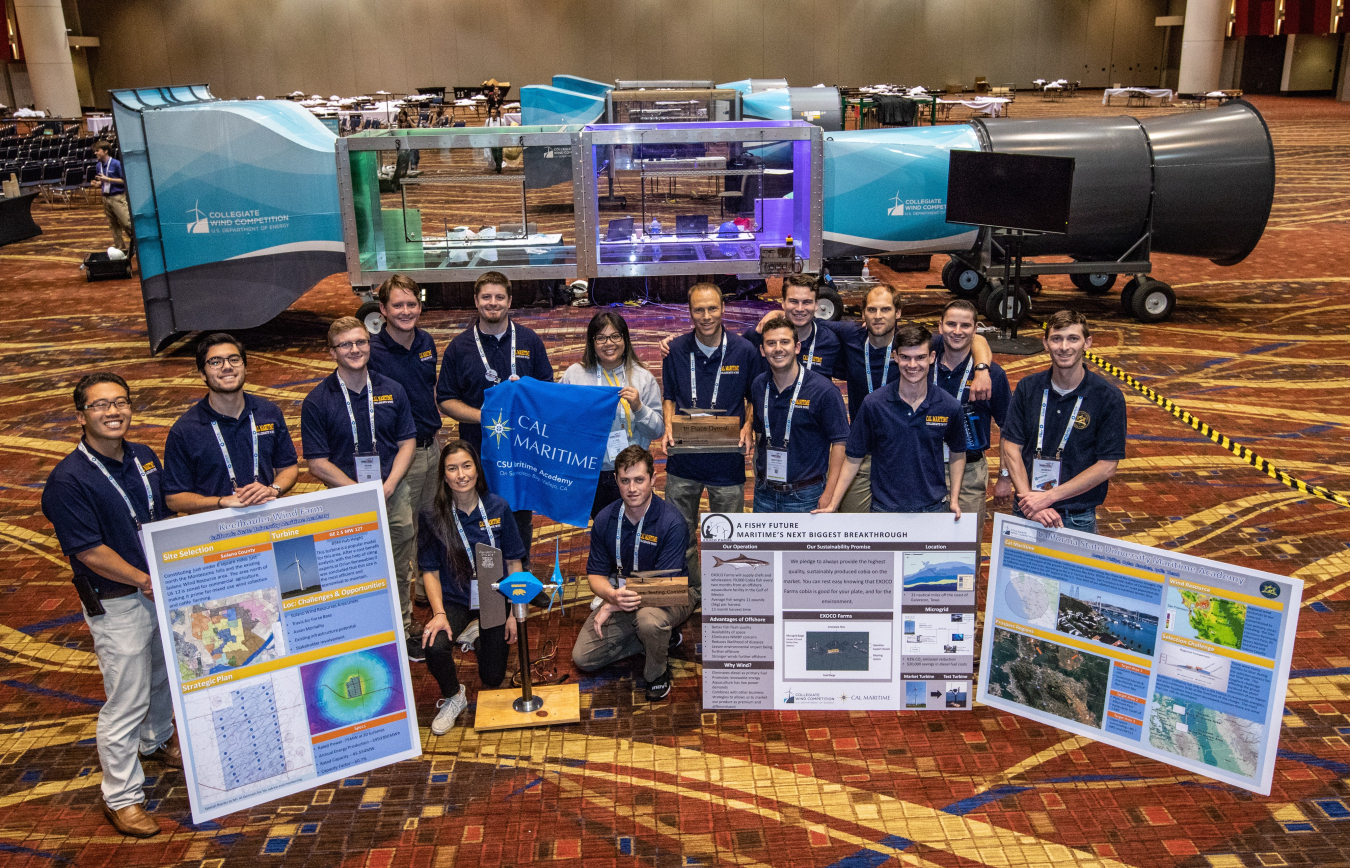

The California State University Maritime Academy team gathers in front of the Gen2 wind tunnel after winning First Place Overall at the 2018 Collegiate Wind Competition in Chicago. Photo by Werner Slocum, NREL 53758

The capabilities of the first-generation wind tunnels were stretched as far as possible on the budget that was provided, but they were limited in both air speed and modularity. We needed a more powerful wind tunnel to better challenge the student teams as they learned more over the first few years of competition.

The Gen2 wind tunnel capabilities include measuring wind speed, temperature, pressure, turbine voltage, turbine current, rotor rotations per minute, and the direction the turbine is facing relative to the wind. In the competition, students must run a test in which they run the power generated by the model wind turbine through a CWC-provided load system while storing excess energy in an ultracapacitor. The wind tunnel monitors the status of both systems and can control whether the turbine is connected to them or not. The entire test section of this wind tunnel is made from clear polycarbonate that allows students and organizers to view the wind turbine model being tested.

The engineering team that designed and built the CWC Gen2 wind tunnel had to consider how the tunnel would be transported to events. The apparatus is modular and sits on large wheels for towing. Photo by Werner Slocum, NREL 53644

How does an engineering team create a wind tunnel? It follows the same process most engineering projects follow—and the same process students are encouraged to use when designing wind turbines for competition at the CWC. Roadman explained the process in three phases:

- Conceptual design—this is the brainstorming phase. It often involves back-of-the-envelope calculations (picture engineers in a restaurant drawing on cocktail napkins). Very basic calculations may be performed.

- Preliminary design—initial engineering calculations are used to scope the design and a single concept is chosen to move forward with. This phase includes calculations to determine if the design is truly feasible with available hardware and manufacturing methods. Components and hardware will be sourced in this phase and manufacturing methods will be determined, but not every nut and bolt will be specified.

- Detailed design—detailed engineering calculations and, potentially, simulations are used to fully specify the design. Calculations need to be executed in enough detail to demonstrate that the design has appropriate safety factors built in. A computer-aided design (CAD) drawing is usually created. Components are fully specified with every nut and bolt, and all hardware, manufacturing methods, and suppliers are finalized. When this phase is complete, engineers can trust that the product will work as intended; they have a fully detailed process for how to manufacture all components and how to assemble the product. Typically, a final design review is conducted where engineers less involved in the process double check all crucial calculations and make sure nothing was missed. Depending on the scale of the project, design reviews may also occur at the end of the conceptual and preliminary phases.

As part of the engineering process, the team started with a design concept and created a CAD design during the design phase of the tunnel. Graphic by Jason Roadman, NREL

After the detailed design phase, we either manufactured the necessary components in-house or subcontracted them out. All of the hardware was ordered. As components started arriving at the lab, the assembly process began.

Troy Boro uses heavy machinery to lift the tunnel off the ground to continue the assembly process. Photo by Jason Roadman, NREL

Once assembled, to commission the wind tunnel, a graded approach was used that gradually tested the wind tunnel's limits and capabilities, addressing any deficiencies. "Safety was paramount at this stage because the hardware was being operated in this way for the first time," said Roadman. After commissioning, a revision stage often takes place, where the product is further refined, and weaknesses are corrected.

Thanks to this tireless team of engineers and technicians, the CWC has a wind tunnel that will serve students competing in the competition for years to come.