Lumileds develops and manufactures LEDs as well as automotive lighting products, and distributes them to customers in the U.S. and abroad.

June 15, 2017

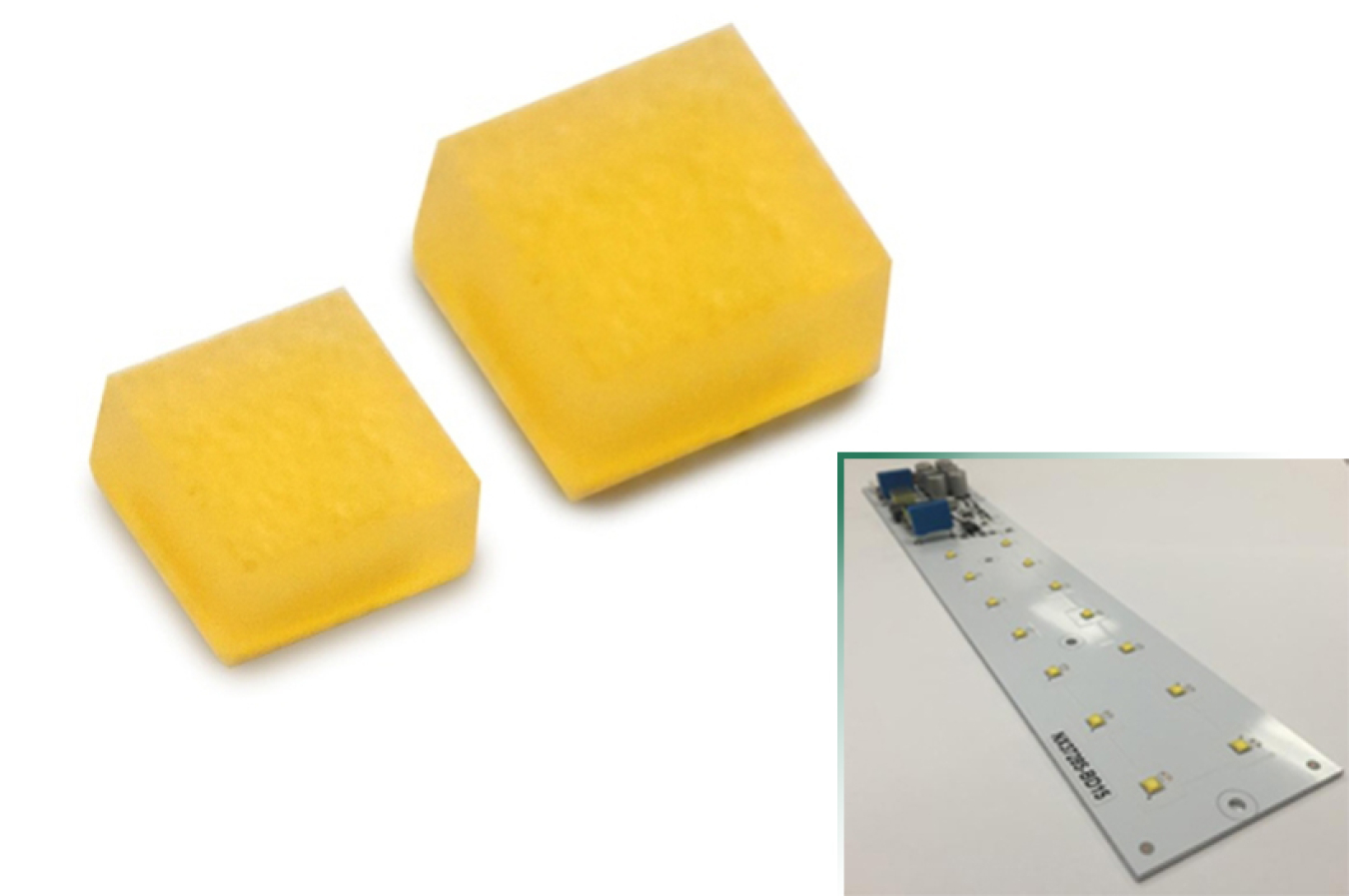

Left: Lumileds’ LUXEON FlipChip White. | Bottom Right: Lumileds’ prototype light engine with integrated switch-mode driver.

Adapted from an issue of the Solid State Lighting weekly Postings.

Solid-state lighting (SSL) is rapidly transforming the lighting industry, and the U.S. has been at the epicenter of SSL innovation. U.S.-based researchers and product developers have been instrumental in toppling cost and performance barriers, and in positioning SSL for rapid market growth. U.S. lighting manufacturers are well positioned to benefit from the SSL revolution, strengthening our country’s position as a leader in the technology. From time to time, the Postings focus on SSL companies that manufacture in the U.S. This is not intended to endorse or promote any of the companies, but rather to motivate and inspire other U.S. companies to follow suit. The philosophy and activities you’ll read about in these profiles are consistent with the recommendations set forth in the U.S. Department of Energy (DOE) white paper “Prospects for U.S.-Based Manufacturing in the SSL Industry.”

Lumileds

Lumileds develops and manufactures LEDs as well as automotive lighting products, and distributes them to customers in the U.S. and abroad. Of roughly 9,000 people employed by the company worldwide, nearly 700 are based in San Jose, CA, where most of the corporate functions are carried out as well as all of the LED R&D leadership and manufacturing of the epitaxy, including the substrate patterning – the high-value portion of the manufacturing process that defines the upper limit of LED performance.

According to chief technology officer Jy Bhardwaj, the most important elements in driving the innovation at Lumileds are epitaxy, die, phosphor, packaging, optics, and electronic systems – all of which are led out of San Jose. Epitaxy is one of the most proprietary technologies to the company – which is the main reason why Lumileds manufactures here in the U.S., where it’s easier to protect intellectual property than it is overseas. Another advantage of manufacturing domestically, Jy adds, is that it provides access to a vast talent pool that draws from the best U.S. universities.

DOE has supported several cutting edge R&D projects at Lumileds that have contributed to boosting the performance of LED chips and modules on many fronts, while also lowering the cost. These improvements often proliferate into multiple Lumileds product lines, which to date have been incorporated into millions of LED lighting products on the market. The improvements also set new performance standards for the entire industry to compete against, improving performance, efficacy, and cost across the board.

For example, DOE R&D support has directly led to the development of the LUXEON Q, LUXEON FlipChip, LUXEON Rebel, and LUXEON S1000 LED package products – all of which are commercially available and offer luminaire integrators a range of features and price points that enable greater flexibility to address the vast range of lighting form factors and performance requirements. The specific advancements achieved in these products include new phosphor deposition approaches, high-voltage LED chip configurations, improvements to red LEDs, and improved manufacturing techniques. Another Lumileds LED package platform developed with DOE R&D support involves the use of advanced patterned sapphire substrates (PSS), an important development that has enabled increased efficiency and light output at low cost, and has been so effective that Lumileds has transitioned most of its LED component products to PSS architecture.

DOE SSL R&D support has also enabled Lumileds to tackle a fundamental barrier to LED performance – efficiency droop at higher current density. Lumileds has teamed with MIT, Brookhaven National Lab, and Sandia National Lab to develop a better understanding of the fundamental physics of droop and develop mitigation approaches that can reduce the cost of high brightness LEDs. In this project, Lumileds provides state of the art LED wafers and epitaxy expertise while the partners provide advanced characterization techniques only available at their facilities, creating a world-class collaboration.

“DOE funding has helped to speed up our research and development in LED lighting by cushioning some of the risk,” observes Jy. “It has enabled some of our most successful products on the market today.” He sees the SSL industry moving from replacement lamps to dedicated LED luminaires, which is shifting the value toward the LED light engine. This means there is more value that a company like Lumileds can offer. Whereas manufacturers were previously constrained by legacy fixtures, now – instead of costing down every possible component – they can create a better system outcome with integrated designs. Moving to dedicated LED luminaires allows for more freedom to maximize the technology’s full range of capabilities, enabling new designs and form factors as well as cost reductions in other parts of the luminaire, such as the optics and heat sinks.

Jy notes that as these opportunities shift value toward the LED and light engine, high luminance and high efficacy are helping to reduce the rest of the overall system cost. In addition, Lumileds does extensive inline testing of its LEDs, so that it knows the entire process well and has a lot of parametric data on each LED produced, which can be programmed into a light engine during manufacturing. This means that instead of binning the LEDs, which loses the traceability of that parametric data and adds cost, the company has the ability to use the data based on the requirements of the application – e.g., by enabling more-accurate color tuning and color consistency, and offering the potential to provide maintenance schedules based on the predicted L70 lifetime of a connected luminaire.

Jy says cutting-edge applications such as connected lighting, horticultural lighting, and human-centric lighting will help manufacturers succeed in the general-illumination market – not only by providing additional markets that generate economies of scale, but also by helping to drive the technology forward in terms of innovation and overall performance. He emphasizes the need for SSL manufacturers to move beyond existing lighting-system architecture to realize the next phase of adoption, which he feels will be driven by high-luminance LEDs and integrated light-engine technology.

As the lighting market shifts to SSL technology, Lumileds is one of many companies that are helping to reinforce U.S. manufacturing and R&D leadership. This will not only help bring significant energy savings through more-efficient lighting products, but will benefit our economy by adding jobs at multiple levels of the supply chain.