A great deal of energy use in buildings goes toward heating, ventilation, and air-conditioning (HVAC).

March 14, 2017A great deal of energy use in buildings goes toward heating, ventilation, and air-conditioning (HVAC). In 2015, HVAC consumed 15.5 quads. The first step in reducing HVAC energy use is reducing heating and cooling load—i.e., the amount of heat that needs to be added to or removed from a building—typically by reducing heat from equipment and lighting; minimizing unnecessary ventilation; designing a tight, insulating envelope; using high-performance windows; and exploiting the building’s thermal mass to store heat and release it later. The Rocky Mountain Institute (RMI) Innovation Center in Basalt, Colorado, takes these strategies to such extremes that it needs no central HVAC system at all! Building energy modeling (BEM) was used to ensure that the RMI Innovation Center would maintain occupant comfort. Even for less extreme cases, BEM can help engineers minimize both HVAC energy use and up-front cost.

Selection, Sizing, Hybridizing, and Control Strategizing

HVAC systems come in a surprising variety of types and configurations. Single-zone systems are controlled by a single thermostat. Multi-zone systems can serve multiple spaces, each with its own thermostat. Heat can be generated using furnaces, electric resistance, solar panels, or heat-pumps that draw heat from air, water, or the ground. Some systems condition air centrally and distribute it using ducts and fans. Some heat and cool water in large central boilers and chillers, pump the water around the building, and—closer to the occupied zones—transfer the heat to air using coils. Others pump hot or cold water through pipes in the floor, ceiling, or specialized panels and let it radiate heat into—or absorb radiant heat from—the space. Water-based systems exploit the fact that water stores 1,000 times more heat per volume than air in order to replace large air ducts and large, noisy fans with smaller water pipes and smaller, quieter, more-efficient pumps. In district configurations, multiple buildings share a single large hot and cold water plant. Mechanical engineers use BEM to select and configure these systems to fit comfort, energy, and cost criteria.

HVAC components like coils and fans operate at peak efficiencies under full loads—defined by air (or water) flow rates and inlet/outlet temperature differentials—and less efficiently at partial loads. Minimizing HVAC system energy use requires choosing equipment that operates efficiently at the loads that are expected to prevail in each specific building. Choosing equipment suited for larger loads is more expensive both up-front and during operation. Unfortunately, most installed systems are oversized to meet the most extreme loads—i.e., the coldest and hottest days of the year—and with safety margins to boot!

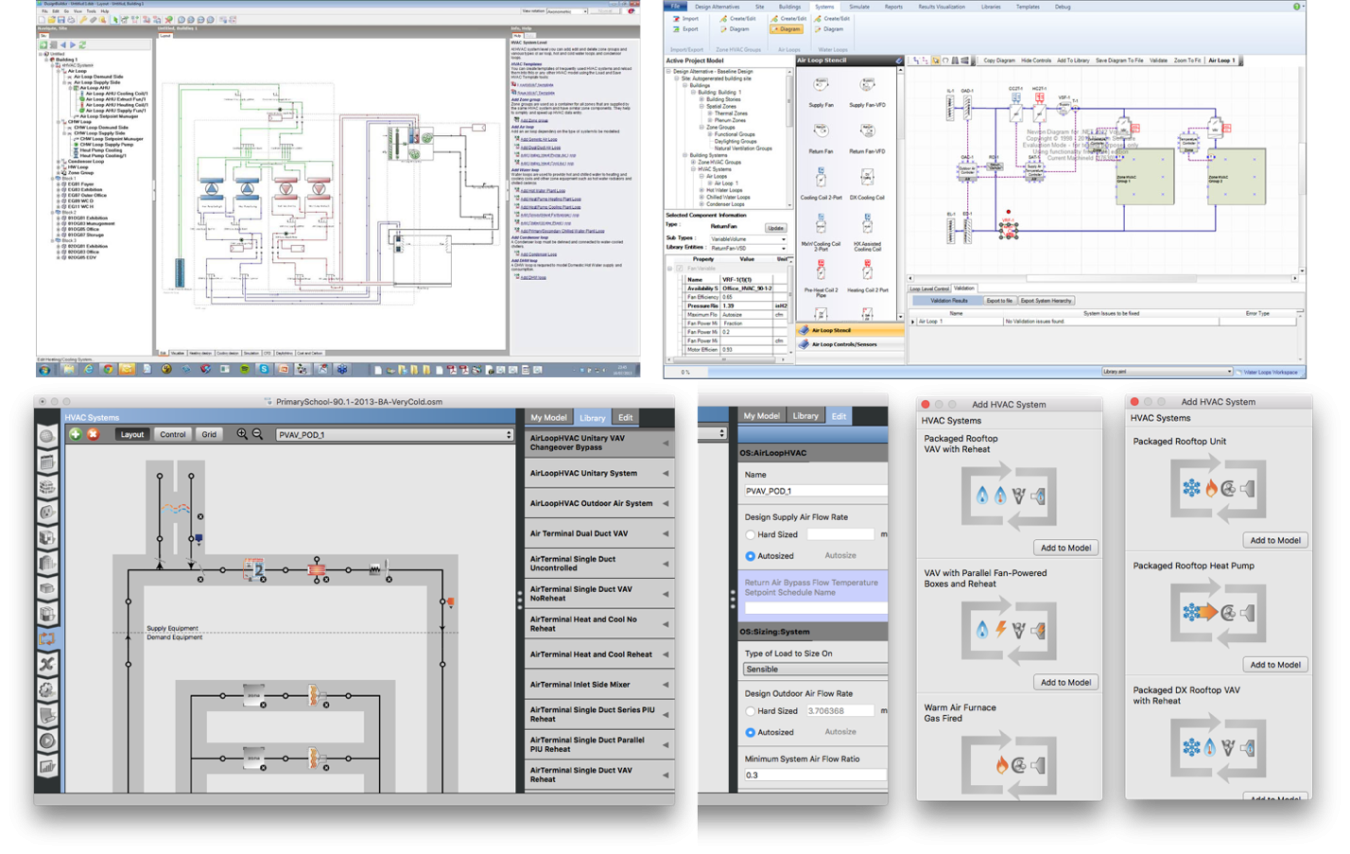

BEM can help engineers design and size systems that are both cheaper and more energy efficient. One way to do this is to couple a small, efficient primary system to handle loads in the common case, with a cheap supplementary system that kicks in under more extreme conditions. Energy-efficient HVAC systems rely on more sophisticated control sequences and often on thermal storage, and as a result are more difficult to size using simple calculations. Engineers can use BEM to design and test control strategies to appropriately size components—BEM can test control strategies under a much wider set of dynamic conditions, as well as much more quickly than is possible to do in a physical building.

EnergyPlus user interfaces like DesignBuilder (top left), Simergy (top right), and OpenStudio (bottom) allow mechanical engineers to evaluate standard HVAC systems, design custom systems, and leverage EnergyPlus’ sizing and controls features.

“Real-Time” BEM

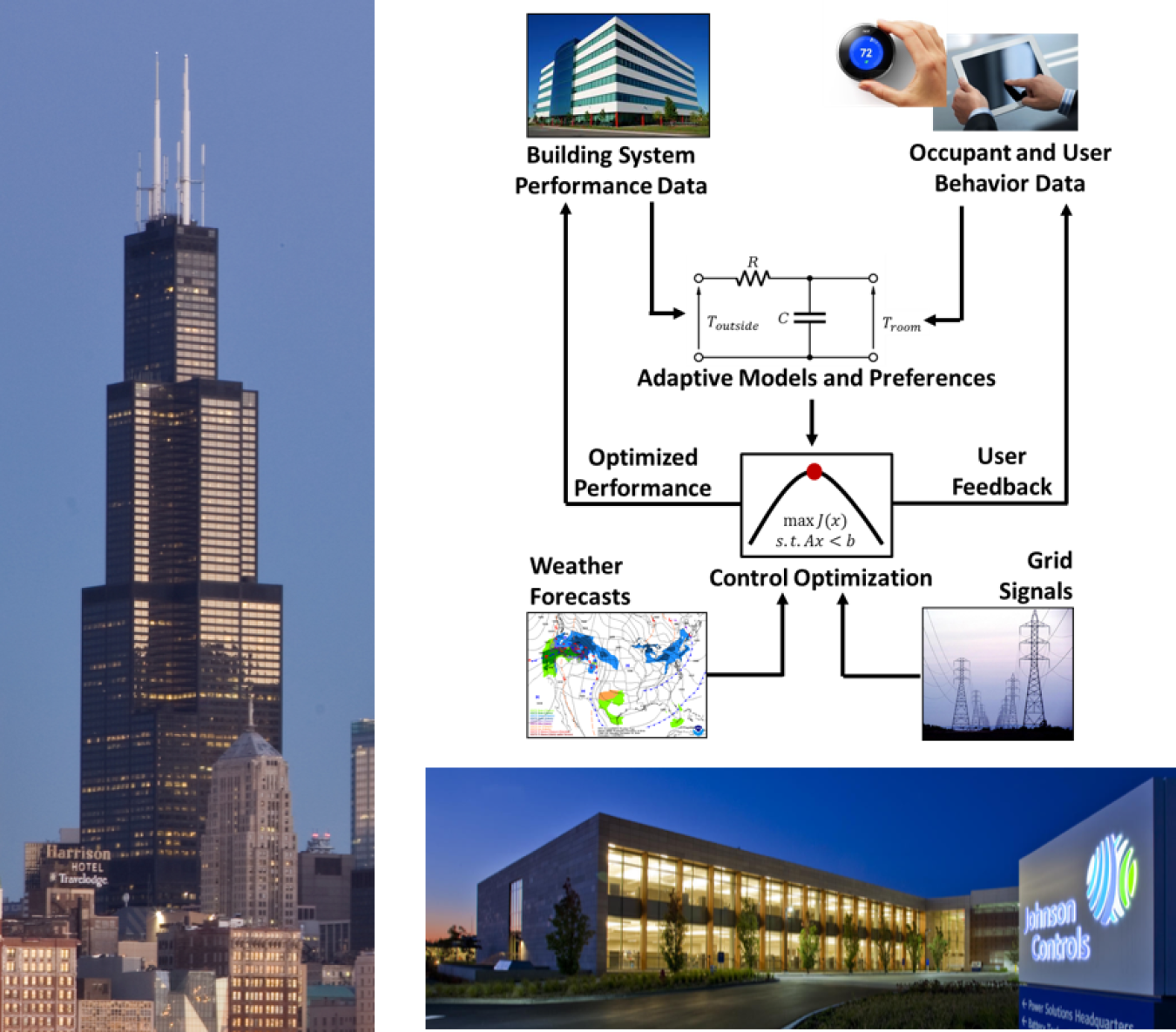

Most BEM applications are “offline,” in that BEM is used to inform decisions that are relatively far in the future. One emerging “online” application is model-predictive control (MPC), which optimizes a building’s HVAC control strategy in real time, using information about building occupancy and use, weather forecasts, and price signals from the grid. MPC feeds this real-time information into a model to evaluate control strategies for the next hours or days, re-evaluating as new information or forecasts come in. MPC applications typically combine coarse-grain models or measured data for those aspects of the building that cannot be controlled—like the envelope or internal conditions—with detailed models of the HVAC system.

Model Predictive Control (MPC) is already established with companies such as QCoefficient using it to help operate the Willis Tower (left) while JCI is experimenting with MPC in its Milwaukee, WI headquarters.

“Next Generation” BEM

With an understanding that control is becoming an increasingly significant and integrated component of building energy-efficiency, the Energy Department is orienting a portion of its research and development program toward the creation of a new platform that integrates established BEM-based architecture and engineering workflows with emerging control design, verification, and implementation workflows. This new platform—which currently goes by the name Spawn-of-EnergyPlus—will allow engineers to write a control sequence once, evaluate it using BEM, and then automatically translate it for execution in a building automation system (BAS). Spawn will also allow HVAC manufacturers to develop proprietary equipment models and plug them into BEM and control workflows. Finally, Spawn will enable BEM to connect to BAS systems in real time, enabling control applications like MPC. Spawn is a collaboration between the Energy Department, the International Energy Agency (IEA), the International Building Performance Simulation Association (IBPSA), and the California Energy Commission (CEC).

Dr. Amir Roth

Dr. Amir Roth is the technology manager for BTO’s Building Energy Modeling (BEM) subprogram and has served in that role since 2010. From 2001 to 2010 he was first an assistant and then an associate professor with tenure of Computer and Information Sciences at the University of Pennsylvania in Philadelphia. He graduated magna cum laude with a B.S. in physics from Yale University and holds a Ph.D. in computer science from the University of Wisconsin—Madison where he won a dissertation award in 2001. He is a member of the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), and the International Building Performance Simulation Association (IBPSA).

Email Amir Roth ►