Windows are responsible for about 10% of building energy loads, or about 4 Quads of energy nationally each year, which increases energy bills, reduces occupant comfort, and drives increased emissions that contribute to a warming climate.

April 1, 2021

When considering a building’s envelope, existing traditional windows are a major energy-management weak point, despite their ubiquity. Windows are responsible for about 10% of building energy loads, or about 4 Quads of energy nationally each year, which increases energy bills, reduces occupant comfort, and drives increased emissions that contribute to a warming climate. But the Lawrence Berkeley National Laboratory (Berkeley Lab), with funding from the Building Technologies Office, have analyzed the capability of energy-efficient, thin triple-pane windows to improve energy efficiency. And with that knowledge, utility companies have begun to offer consumers rebates that help them overcome the first-cost barrier to installing efficient, thin triple-pane windows that cost-effectively reduce the energy needed to maintain a comfortable temperature.

An Improved Technology – Thin Triple-Pane Windows

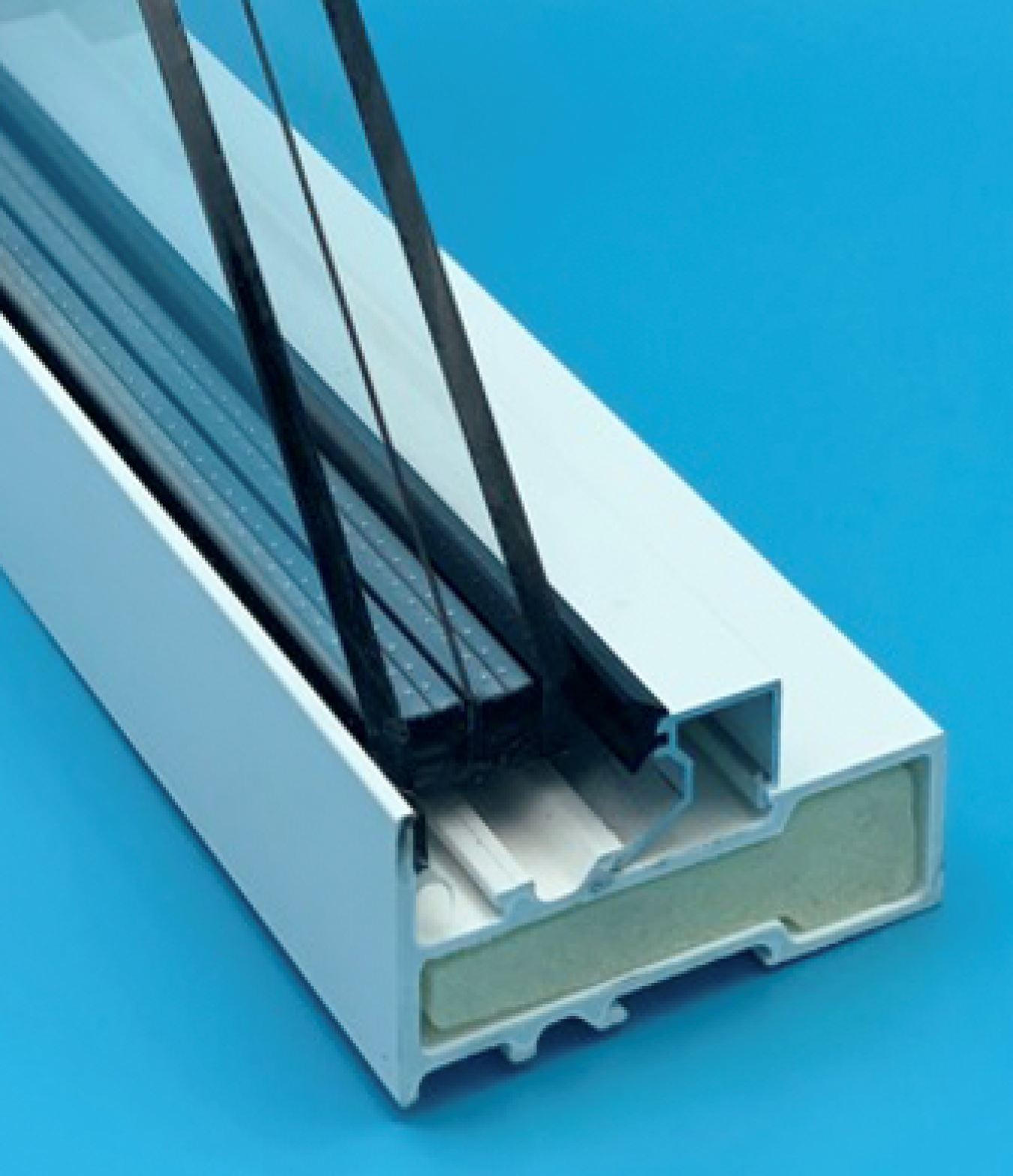

The concept of adding a third pane to windows is not a new idea, but previous iterations of this technology were packaged in glass that was too wide and too heavy to easily be used in new buildings or retrofits. With recent advances in window technology, thin triple-pane windows now feature thinner sheets of glass, making them lighter and more suitable for minimally invasive retrofit applications.

Thin triple-pane windows are currently the most energy-efficient, commercially available windows on the market, and they well out-perform single- and double-pane versions in energy and cost savings. They have two low-emissivity (low-e) coatings, tightly sandwiched together with spacers that create not one, but two sealed gas pockets that significantly enhance a window’s insulative capacity. The gas pockets are filled with argon or krypton, which are highly insulative, nontoxic, odorless, and colorless gases. The three separated panes of glass use the gas-filled spaces to reduce the heat transfer from inside to extreme conditions outside, very hot in summer and very cold in winter, thus keeping comfortable temperatures inside the home. This is perhaps more important than ever as climate change continues to bring more frequent and extreme weather events that homebuilders may not have anticipated when the homes were constructed.

Energy and Cost Impacts

When thin triple-pane windows are installed in new buildings or used as replacements for old windows in existing ones, the energy consumption and greenhouse gas emissions of buildings can be significantly reduced to minimize cooling and heating needs and costs. Berkeley Lab recently found that thin triple-paned windows could potentially reduce energy usage in new construction by 16% if installed in Minneapolis, Minnesota (a cold climate), 12% in Washington, D.C. (a more temperate climate), and 7% in Houston, Texas (a predominantly hot climate) by utilizing these high-performance windows in place of the typical ENERGY STAR-rated products most commonly used today.1 Beyond the energy savings potential, these high-performance windows may allow the use of smaller HVAC systems and help builders comply with or even exceed the latest building energy codes like the International Energy Conservation Code (IECC) of 2021.

With these new advancements come higher prices. Thin triple-pane windows, which cost 10-40% more than typical windows, are out of reach for some homeowners’ budgets—at least for now. However, as the volume of thin triple-pane products increases, the price premium will come down. This will make them more competitive with existing products by providing faster paybacks and lessening the need for rebates, which could be phased down or withdrawn.

Over the past five years, BTO and Berkeley Lab have worked with utility companies who want to bridge that cost gap for customers by offering rebates to those who want to install these higher-performance windows. With BTO funding, Berkeley Lab supported PG&E, California’s largest utility company, and Connecticut’s Eversource Energy with technical analysis that enabled the utilities to provide concrete financial support via rebates.

These rebate programs are already seeing success in helping beneficial climate and energy-efficient investments, like higher-performing windows, reach more people. Eversource Energy’s current offering of a $100 rebate per window for each window replaced with an ENERGY STAR-certified thin triple-pane window has already driven sales. One thin triple-pane manufacturer participating in the program said that since joining the rebate program, “Our thin triple-pane sales in Connecticut are by far the highest in comparison to other states.” Through efforts like this, utilities like Eversource are driving interest and market adoption of high-performance windows.

Thin Triple-Paned Windows Market Deployment

Berkeley Lab is also collaborating with growing numbers of manufacturers who are eager to be involved and who now offer high-performance windows to their customers, including industry movers like Renewal by Andersen, Cornerstone Building Brands, and Alpen HPP. For consumers that are not in the market to replace windows, or where replacement is not possible, the Department also recommends affordable window attachments such as ENERGY STAR low-e storm windows or other window attachments that are rated by the Attachment Energy Rating Council.

By supporting work that drives the adoption of highly energy-efficient window technologies, BTO is addressing the climate crisis and working toward President Biden’s goal of cutting the U.S. building sector’s carbon footprint in half by 2035. BTO continues to fund projects that drive adoption of energy-saving technologies, and promote energy-efficiency accessibility, while prioritizing occupant comfort. BTO expects to increase its efforts focused on deployment moving forward.

.....

1 Hart Robert, S. Selkowitz, and C. Curcija. 2019. Thermal performance and potential annual energy impact of retrofit thin-glass triple-pane glazing in U.S. residential buildings. Build Simulation 12: 79–86.