Feedstock-conversion interface RD&D activities address challenges related to the behavior and performance of biomass in supply, preprocessing, and conversion process operations. Current challenges include quantifying variability of materials, development of mitigation strategies, evaluation of feedstock performance, system reliability, and behavior modeling. These challenges are being addressed though the Feedstock-Conversion Interface Consortium, coordinated by RCR in collaboration with the Conversion Technologies and System Development and Integration programs.

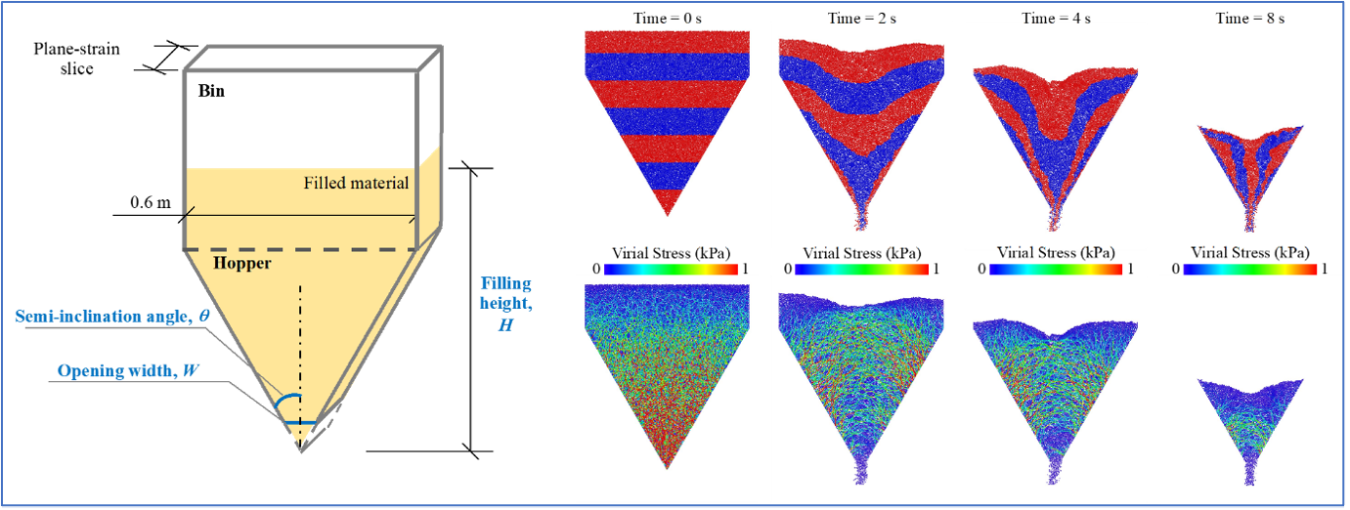

Hoppers are used in biorefineries at various locations. Downtime of a biorefinery can often occur due to the clogging of a hopper, if the hopper design mismatches the bulk material properties. Therefore, robust hopper design for granular biomass is researched in FCIC by using advanced experimentation and experiment-validated computational modeling. Shown in the figure are simulation snapshots of granular biomass discharge from a wedge hopper. Top right: the red and blue color bands are used to visualize the flow patterns. Bottom right: stress is used to visualize the intensity of intergranular motions in the bulk material (red refers to the strongest and blue refers to the weakest). Image courtesy of Idaho National Laboratory.