In 2019, after three years of fuel and engine research, the Department of Energy’s (DOE’s) Co-Optimization of Fuels & Engines (Co-Optima) initiative selected and recommended 10 different bio-blendstocks that could be used to make gasoline fuel...

April 18, 2023

Author: Dr. Lynn Wendt, Laboratory Relationship Manager, Idaho National Laboratory

Read Lynn's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

In 2019, after three years of fuel and engine research, the Department of Energy’s (DOE’s) Co-Optimization of Fuels & Engines (Co-Optima) initiative selected and recommended 10 different bio-blendstocks that could be used to make gasoline fuel burn cleaner, more efficiently, and with lower greenhouse gas (GHG) emissions. With prenol, identified as a leading candidate, the next consideration became finding the best options for blending prenol to make real commercially relevant gasoline.

Researchers led by Dr. Maria Magdalena Ramirez-Corredores of Idaho National Laboratory (INL) have published two papers in the Elsevier journal Fuel addressing this issue. The first, The Intrinsic Value of Bio-Blendstocks: Prenol as a Case Study, examines the higher octane and lower vapor pressure potential of prenol—elements the Co-Optima initiative previously identified as critically important to improving engine performance. The second paper, The Formulation of a Base Fuel for Gasoline-Type Bio-Blendstocks, delves into which base fuels might work best with prenol and other bio-blendstocks identified by Co-Optima researchers as candidates for boosting octane and lowering vapor pressure.

Prenol (3-methyl-2-buten-1-ol) is an alcohol that occurs naturally in citrus fruits, grapes, raspberries, and tomatoes. It is also manufactured industrially for use in pharmaceuticals and perfumes.

Because of its promising fuel performance, researchers have studied its synthesis from renewable sources. For all the promise new bio-blendstocks offer, they will still have to be blended with base fuels refined from crude oil. For them to burn cleaner, the base fuels will have to be different from the hydrocarbon-based blendstocks that are refined to accept 10% bio-ethanol.

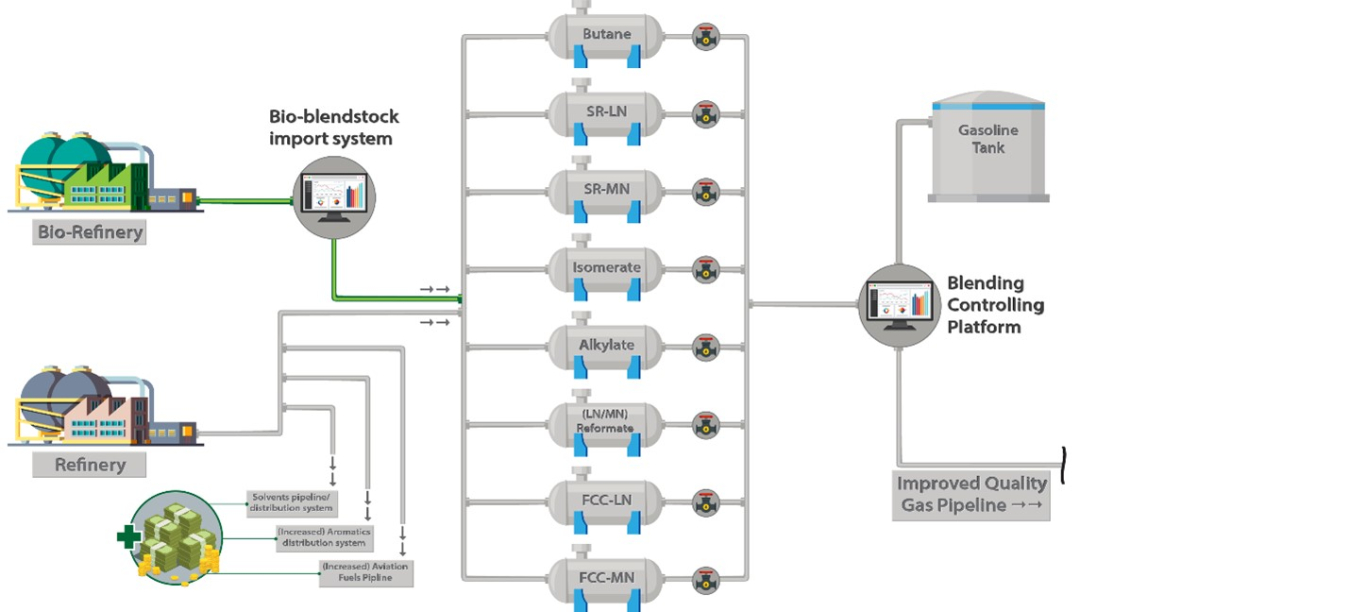

In the United States, more than 95% of the gasoline sold at the pump contains 10% bio-ethanol. To accommodate it as a bio-blendstock, refineries manufacture a base fuel called Blendstock for Oxygenate Blending (BOB). Because BOB composition is proprietary, formulations might differ from one refinery to the next, but the mixture is optimized to meet all required U.S. government specifications (ASTM D4814) once ethanol is added. BOB fuel is made of products refined from crude oil, such as butane (the most volatile component) to light, mid-range, and heavy naphtha. Typically, the refiner has a wide range of different hydrocarbon streams to use. “A refinery might use up to 15 different blendstocks in the formulation of the gasoline it sends to market,” Dr. Ramirez-Corredores said.

As a bio-blendstock, ethanol produces higher vapor pressure, which causes the odor noticeable at the pump and which represents lost fuel that must be factored into the cost. One of Co-Optima's goals has been to identify bio-blendstocks with lower vapor pressure. Co-Optima researchers screened more than 1,000 options to pinpoint high-performing blendstocks that could potentially be produced at commercial scale from the estimated billion-ton annual supply of domestic biomass resources. From there, researchers identified 10 blendstocks that could combine with existing fuels to improve vehicles' carbon footprints and engine performance.

“[Bio-blendstocks] capable of improving engine performance and efficiency create direct benefits to society through the economic benefits to the end-user and the reduction of GHG emissions to the environment,” Dr. Ramirez-Corredores wrote in her paper on prenol. “However, their production and commercialization need to create equivalent benefits to producers (refineries and biorefineries) and retailers.”

“Our work demonstrated that while BOBs are suitable for blending in ethanol, any other bio-blendstock will require adjustments or reformulation of the base fuel,” Dr. Ramirez-Corredores said.

“For the Co-Optima-selected bio-blendstocks like prenol, we defined a preliminary base fuel formulation and named it Blendstock for Co-Optimized Blending (BCOB). Since ethanol is a high vapor pressure bio-blendstock, the work was oriented towards its replacement with the highest possible content of Co-Optima bio-blendstocks that would lower vapor pressure.”

The intrinsic value of bio-blendstocks creates benefits for refiners and biorefiners [Drawing reproduced from Ramirez-Corredores, M. M.; Vega-Montoto, L. and Patzelt, R. The formulation of a base fuel for gasoline-type bioblendstocks. Fuel 2022 324 (Sep.), #124655, 7pp, with permission from Elsevier].

The second Fuel paper compares binary mixtures of prenol volumetrically–10%, 20% and 30%– blended into five different gasoline blendstocks with a multi-component blend, which resembles real gasoline. The blends were analyzed at commercial fuel testing facilities in California and Texas. The researchers found that low-volatility/octane-boosting bio-blendstocks like prenol might result not only in cost savings and higher-value fuels, but also reduced emissions and lower sulfur. However, more work needs to be done to understand how olefins and aromatics interact with prenol and how new blendstocks can comply with ASTM D4814 regulations.

Furthermore, the study confirmed that at least two specified properties—washed gums and sulfur content—can be met by a finished fuel containing 10% to 20% bio-blending grades. Gums occur when hydrocarbons in gasoline react with absorbed atmospheric oxygen to form resinous, non-volatile materials that impair fuel combustion and increase the amount of noxious exhaust gases. Deposition of gums in the engine system causes engine wear as well as adverse effects on its efficiency, performance, and durability. Sulfur is a natural component of crude oil that impairs the effectiveness of emission control systems and contributes to air pollution if not reduced or removed.

Dr. Lynn Wendt

Dr. Lynn Wendt serves as the Laboratory Relationship Manager to the U.S. Department of Energy’s Bioenergy Technologies Office (BETO). Dr. Wendt is also a senior research scientist in the Energy and Environment Science and Technology Directorate at Idaho National Laboratory (INL). She has served as a principal investigator for multiple projects sponsored by BETO and has contributed to strategic planning for INL’s Biomass Feedstock National User Facility and associated programs. Dr. Wendt holds a bachelor’s degree in biochemistry from the University of Minnesota, a master's in biology from Idaho State University, and a Ph.D. in environmental science from the University of Idaho. Dr. Wendt is a bioenergy research expert in post-harvest physiology and chemistry of biomass storage systems and microbial systems for bioenergy feedstock supply chain processes. She has pioneered the development of biomass and algae material storage and handling systems that stabilize biomass materials while increasing biomass value during short- and long-term storage. Her 25 biomass-related publications and 3 patent applications are the authoritative reference on value-add biomass storage systems.