A marine research engine at the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) is providing scientists with valuable insights into biofuel design for large ocean-going vessels (OGVs) in a multi-lab project focused on reducing total life-cycle carbon emissions from this vital transportation sector.

September 25, 2024Dr. Erin Webb

Dr. Erin Webb is Laboratory Relationship Manager for the DOE Bioenergy Technologies Office at Oak Ridge National Laboratory. She also leads the Bioresource Science and Engineering Group at ORNL and holds a joint appointment in the Department of Biosystems Engineering and Soil Science at the University of Tennessee, Knoxville.

Erin has been on staff at ORNL since 2007, cultivating expertise at the intersection of bioresource science, engineering, and economics. In her personal research for BETO, she focuses on simulation and analysis of supply chains to deliver biomass as a feedstock to produce fuels, products, and power. Her leadership focuses on developing sustainable and reliable bioresource production systems while preserving ecosystem services.

Recently, Erin has also taken on the role of co-lead for the Circular Bioeconomy Systems Convergent Research Initiative for the UT-Oak Ridge Innovation Institute, a joint venture between ORNL and UT that aims to pioneer the shift toward low-energy and low-carbon-intensity circular agriculture and manufacturing. She holds a Ph.D. in agricultural and biological engineering from the University of Florida, an M.S. in biosystems engineering from the University of Kentucky, and a B.S. in agricultural engineering from the University of Tennessee.

A marine research engine at the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) is providing scientists with valuable insights into biofuel design for large ocean-going vessels (OGVs) in a multi-lab project focused on reducing total life-cycle carbon emissions from this vital transportation sector.

When the International Maritime Organization (IMO) announced in 2023 that the global shipping industry should achieve a net-zero greenhouse gas (GHG) goal around 2050, scientists at DOE’s national laboratories knew their work on biofuels for marine use would be needed to meet the revised target. Their efforts are concentrated on large OGVs like cargo and container ships, which account for more than 80% of all transported goods and 3% of global GHG emissions.

Today, marine vessels largely run on residual fuel oils, which, until recently, contained up to 3.5% sulfur and were referred to as heavy fuel oil (HFO) or bunker fuel. Newer regulations have resulted in the production of very low sulfur fuel oils, with a sulfur content no greater than 0.5%. The residual nature of these fuels means that they, along with asphalt, are the leftover products remaining after separation of the distillate fraction (which contains gasoline, diesel, and lubricant oils) from a barrel of crude oil. As fossil fuels, their use in shipping is a significant contributor to GHG emissions. To put that contribution in perspective, if shipping represented a country, it would be the sixth largest GHG emitter in the world.

Multi-lab collaboration

A maritime sector powered by biofuels is steering closer to reality with the recent progress made by researchers from ORNL, the National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), and Argonne National Laboratory (ANL) through a study funded by the DOE’s Bioenergy Technologies Office (BETO) to investigate the feasibility of using biofuels in OGVs.

ORNL is leading the study and contributing engine and emissions expertise, with NREL providing bio-oil production and technoeconomic analysis, PNNL providing bio-crude production and technoeconomic analysis, and ANL supporting the study with lifecycle, scale-up analysis and engine expertise. As part of the study, PNNL and NREL produced biointermediates made from fast-pyrolysis and hydrothermal liquefaction oils — a promising alternative to residual fuel oils — that were tested for the first time in a unique marine research engine at DOE’s National Transportation Research Center (NTRC) at ORNL.

Navigating around technical barriers

A majority of large merchant vessels use large two-stroke engines instead of four-stroke engines. This means they can burn lower combustion quality fuels like biointermediates. These biointermediates can be derived from a large variety of feedstocks at a relatively lower cost, however in many instances they still need some level of upgrading or blending before they’re ready to drop in for use in these large engines. Researchers are working to address the technical challenges associated with incorporating these fuels into marine engines. Primary areas of concern include overcoming blend stability challenges and improving compatibility with the vessel’s infrastructure materials.

Blend stability is important to prevent clogging and plugging issues in the fuel system. This can originate from a phenomenon called asphaltene precipitation if the blended biointermediates are incompatible with the heavy fuel oil or very low sulfur fuel oil. It is important to note that this phenomenon can also occur when blending two or more traditional fossil based HFOs with each other if they are too dissimilar. Removing water and other oxygenates can improve biointermediate blend stability. In addition, the high acidity of pyrolysis oils can corrode a vessel’s components, including gaskets and seals. Recent ORNL studies have shown that corrosion causes no issue for fuel system metals if blend levels with pyrolysis oils remain below 50%.

Enter the Enterprise

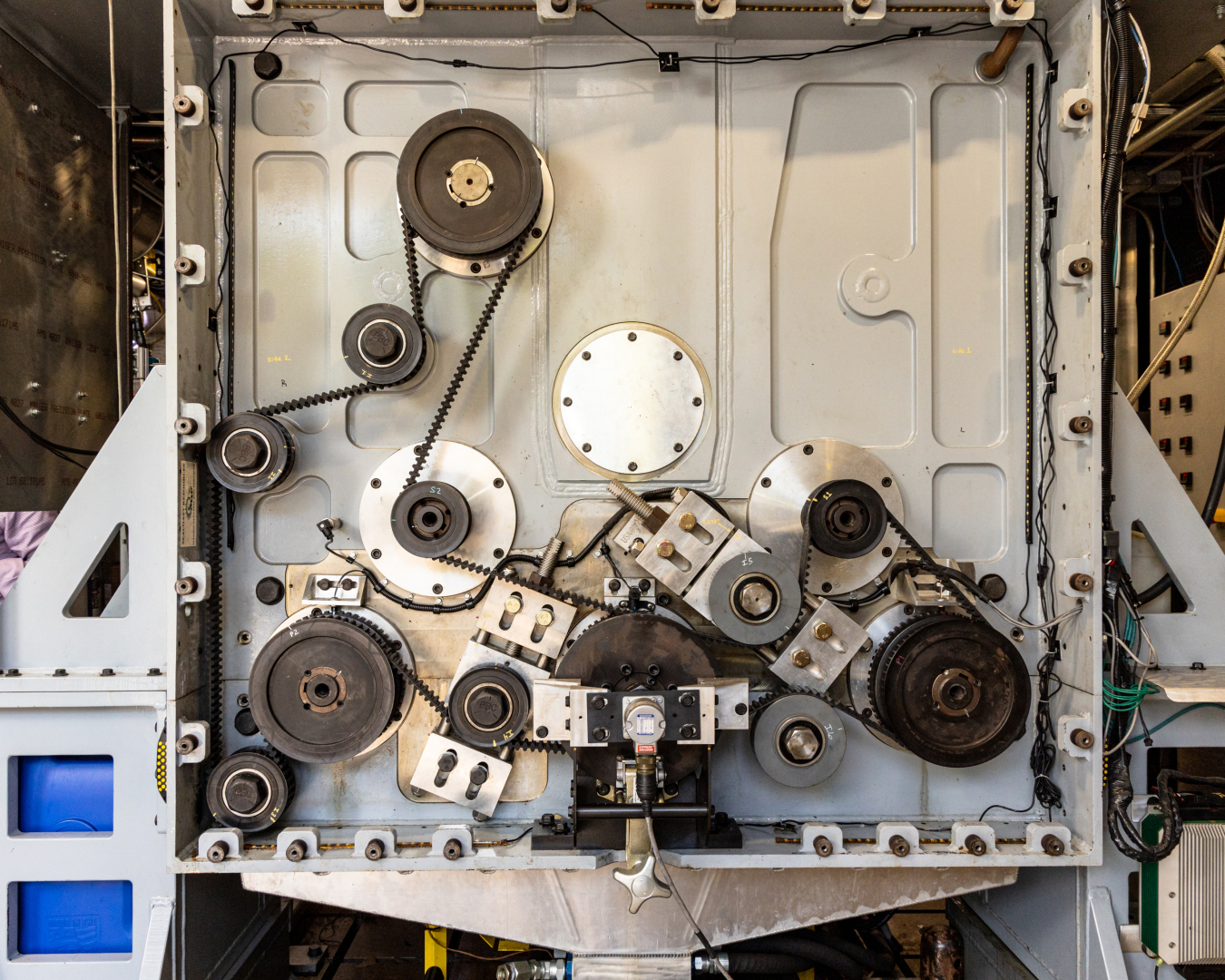

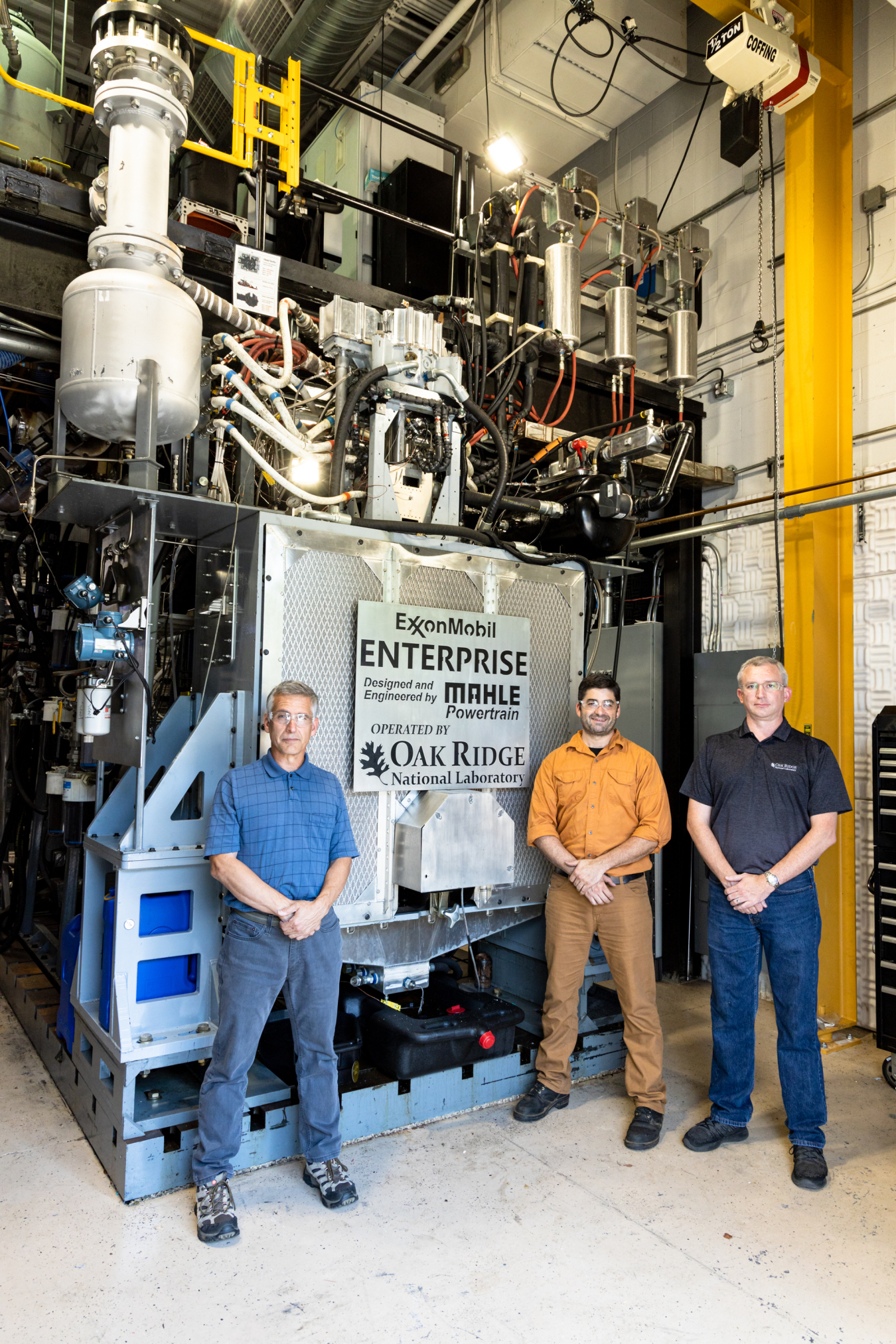

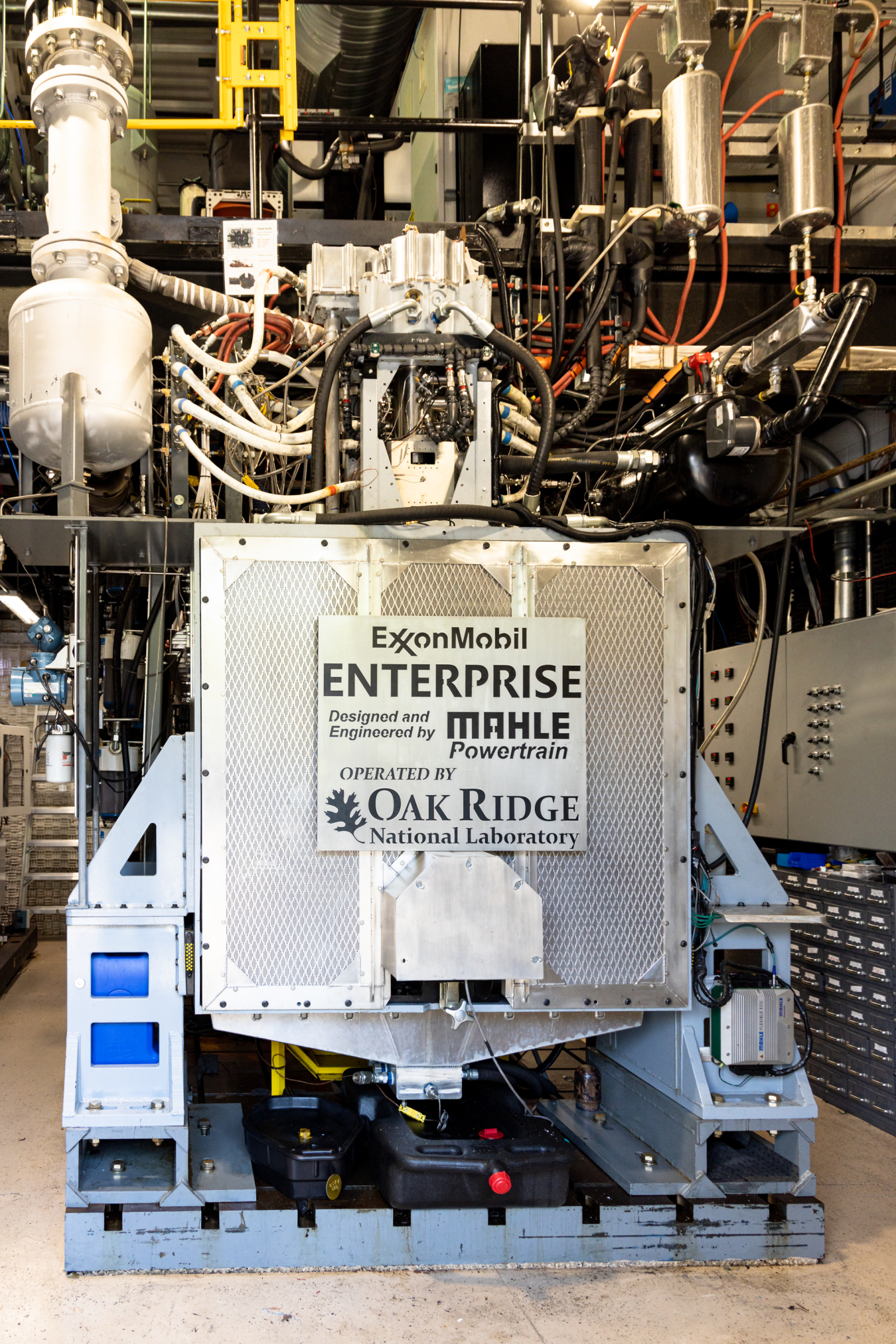

Testing biointermediates is possible with a flexible-fuel, single-cylinder marine research engine, known as the Enterprise, that stands 12 feet tall and weighs more than 16,000 pounds. With a rated speed of 625 rpm to match the linear average piston speed of a full-scale engine, the Enterprise can replicate many of the key features of low-speed two-stroke marine diesel engines. Even at these impressive dimensions, the Enterprise is still 1/10 of the scale of a full-scale engine. The engine was originally commissioned in 2016 through a partnership between ORNL and ExxonMobil to advance the development of marine lubricants. This collaboration established credibility with the maritime community and supported ORNL leading the multi-lab feasibility study that was initiated by BETO in 2021.

ORNL researchers took samples of mildly hydrotreated fast pyrolysis (FP) and hydrothermal liquefaction (HTL) biointermediates produced by NREL and PNNL and blended into a base very low sulfur fuel oil. The HTL bio-crude was derived from municipal waste, and the FP bio-oil was derived from wood waste. Blends of 10% and 20% by volume of HTL bio-crude and 10% by volume of FP bio-oil were tested in the Enterprise at several steady-state speed and load operating conditions. Three engine operating conditions were demonstrated with fixed speed and torque: low load/speed for maneuvering, medium load/speed for slow steaming, and high load/speed for full steaming operation. The engine was fully warmed up before data collection began and a switch between the fuels was made at each operating condition without varying the engine’s calibration.

Powering up to higher blends and testing at sea

The testing represented a milestone achievement and marked the first time a marine diesel engine was powered by an FP or HTL biointermediate. It also proved that the engine could perform well with the 10–20% blend levels. From a data standpoint, however, there was no notable impact on the engine’s carbon emissions or combustion phasing and duration for these low-level blends. The timing when combustion, or fuel burning, occurs in an engine cycle impacts the power, performance, emissions and overall fuel efficiency. By performing the testing with these blends of up to 20% biointermediates, there’s now confidence to move forward to the next phase.

Researchers plan to operate the engine with higher blend levels in the near term as larger fuel quantities become more readily available from commercial vendors. Higher blend level testing will help provide further insight into the suitability of these fuels for engine operation and provide additional data on emissions impacts. Planning is underway to move the testing out of the laboratory setting and onto the sea with onboard ship trials planned by 2027. Collaborations are being explored with potential partners and fuel sources.

The U.S. also has ample resources to produce renewable biomass feedstocks for use in marine applications. The 2023 Billion-Ton Report identifies a potential 1.1 to 1.5 billion tons of biomass availability annually to support bioenergy production, biomaterials, and renewable fuels for hard-to-electrify sectors like marine and aviation. Industry and other stakeholders can access interactive maps and data from the report through the BioenergyKDF website.

Dr. Erin Webb is Laboratory Relationship Manager for the DOE Bioenergy Technologies Office at Oak Ridge National Laboratory.