U.S. Department of Energy Bioenergy Technologies Office (BETO) Bioprose: Bioenergy R&D Blog, Dr. Zia Abdullah from the National Renewable Energy Laboratory addresses these questions—and others—about marine biofuels, which could be critical for decarbonizing the shipping industry. From what they might cost to how much the United States might make in the future, discover five takeaways from a study on marine biofuels, supported by BETO and the U.S. Department of Transportation Maritime Administration.

August 8, 2024Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NREL, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►

It’s not hyperbole: global trade depends upon the sea. Every year, 80% of the world’s goods are hauled between continents by giant ships. These boats, known as cargo ships or freighters, come with large tanks, vessels, or metal shipping containers to hold a range of goods, from produce and foodstuffs to the materials, parts, and finished products we can’t live without.

Propelling massive ships around the world requires lots of energy created by burning thousands of gallons of fuel. The industry uses an estimated 2.5 billion barrels of fuel every year—primarily heavy fuel oil made from the cheap leftovers of gasoline, diesel, and jet fuel production.

The International Maritime Organization has set targets for slashing its carbon footprint and reducing air pollution from burning heavy fuel oil—targets that largely hinge on a new line of sustainable marine fuels. For ships leaving the United States, biofuels made from abundant renewable carbon resources like forestry waste, garbage, and corn stover could play a key role. But just how much biomass is available to make marine biofuels? If so, what might it cost?

To provide answers, National Renewable Energy Laboratory (NREL) analyst Eric Tan and a team of colleagues published a detailed analysis of sustainable marine fuels in the journal Biofuels, Bioproducts and Biorefining. Here are five key takeaways from the study, supported by the U.S. Department of Energy’s (DOE) Bioenergy Technologies Office (BETO) and the U.S. Department of Transportation’s Maritime Administration (MARAD).

1. The United States Has Abundant Resources for Making Marine Fuel

Like biofuels for cars, trucks, or aircraft, sustainable marine fuel can be made from all kinds of organic materials: soybean hulls, logging waste, animal manure, garbage, and even seaweed. Research shows the United States has tons of these resources available—with the potential for over 1 billion tons available every year.

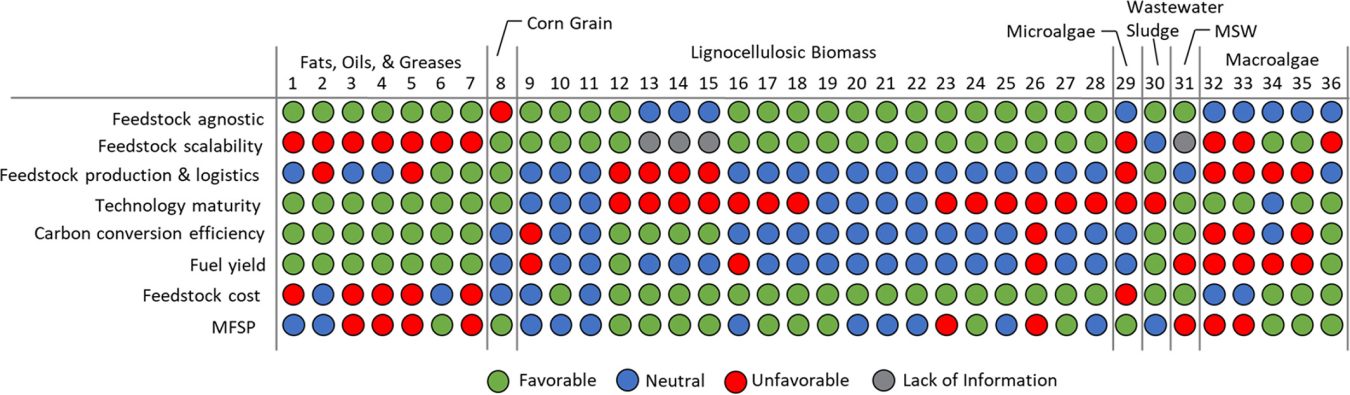

Researchers have developed many technologies to systematically break down these resources—called “feedstocks” in the world of biofuels—and refine them into low-carbon marine fuels like renewable diesel, catalytic fast pyrolysis bio-oil, and hydrothermal liquefaction bio-crude. For example, fibrous and woody feedstocks—like corn stover or residues created from logging—can be preprocessed in several ways (e.g., hydrolysis, pyrolysis, gasification) to yield sugars, oils, or gases. The industry can then upgrade these intermediate products into liquid fuel with the help of catalysts or microbes.

2. Abundant U.S. Resources Can Translate into Millions of Tons of Marine Fuels

So just how much fuel could the United States make? After surveying the feedstocks and technologies available, the researchers did the math: as much as 114 to 245 million metric tons annually if all feedstocks were dedicated to marine fuel. Importantly, those estimates do not consider market forces that will draw feedstocks into other transportation sectors such as aviation, medium- and heavy-duty, and off-road, as well as other industries, such as biopower, biochemicals, and bioplastics. For context, the entire globe consumed around 200 million metric tons of petroleum-based marine fuel in 2020.

Of course, the large range of future sustainable marine fuel production illustrates the impact of economics and industry maturity on the biofuel market. If demand is high, companies can sell fuel for a higher price, making it profitable for them to use more expensive feedstocks to make more fuel. And—as with many industries—biofuel companies’ capacities will likely grow with time as they put down roots, expand their operations, and fine-tune their supply chains.

3. Fuel Costs May Vary Depending on Industry and National Priorities

The cost of fuel is top of mind for the shipping industry. And no wonder—it represents more than half of the total operating expenses for a typical company. To help the industry know what to expect, the researchers outline two scenarios for future sustainable marine fuel costs.

The first scenario assumes the United States prioritizes making as much marine fuel as possible, no matter the cost. The second scenario prioritizes the lowest cost possible but results in smaller fuel supplies. Results suggest prices could range from $1,798 to as low as $758 per metric ton of fuel.

4. We Have Options to Lower Fuel Costs Over Time

These projections suggest that producing large volumes of sustainable marine fuel could be more expensive than today’s fossil fuel-based heavy fuel oil, which was $800 per metric ton in 2022. However, strategies are available to help chip away at the cost of producing a barrel of sustainable marine fuel:

- Use Cheap Feedstocks: Fuel producers can lower costs through feedstock strategies—using cheaper, lower-quality resources such as municipal solid waste or adopting integrated landscape management strategies.

- Improve Supply Chains: Biorefineries can streamline their supply chains, such as finding ways to make feedstock harvesting, delivery, and storage more efficient as fuel demand grows.

- Innovate, Innovate, Innovate: Industry can invest in R&D to improve the efficiency of their biofuel technologies—like using infrastructure already in the ground to reduce upfront costs or improving catalysts to wring out every joule of energy from a ton of biomass.

- Make Coproducts: Lastly, companies can make additional profit by turning materials leftover from fuel production into high-value coproducts (such as bioplastics, biodetergents, and more).

5. Incentives Could Hasten Wider Adoption

Technical innovations and business strategies are not the only way to lower the cost of sustainable marine fuel. A variety of incentives, designed with the maritime sector in mind, could help offset the cost of higher priced fuel and invigorate adoption. These include financial schemes developed in collaboration with individual ports likened to the “Clean Inland Shipping and Sustainable Logistics in Rotterdam”; programs that encourage operators to reduce air pollution through decreased port dues or other incentives; and well-designed state- and federal-government credits, funds, taxes, or standards that favor fuels with lower carbon intensities.

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.