Algae turn sunlight and carbon dioxide into biochemical energy. These researchers use genetic engineering, analysis, and material science to turn that energy into opportunity.

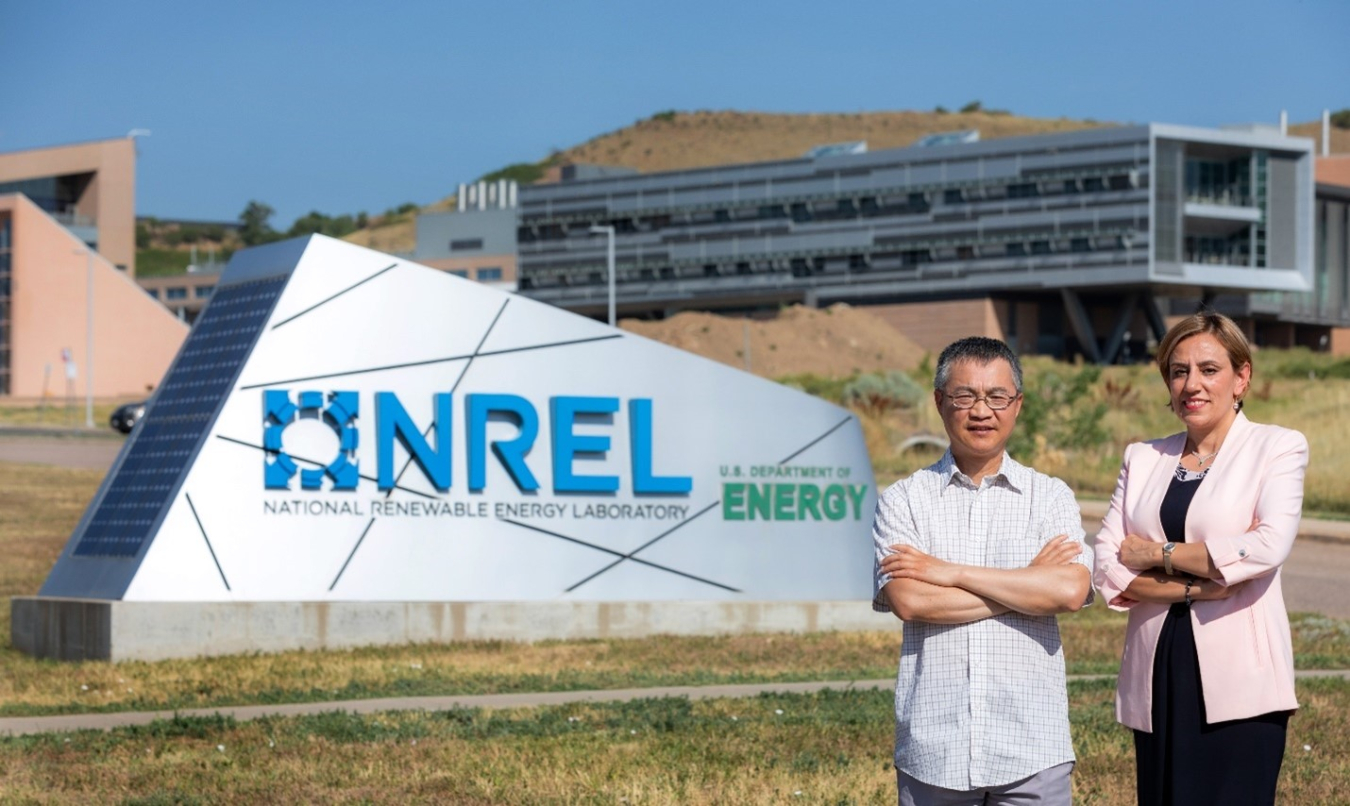

June 6, 2023Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NREL, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►

Algae turn sunlight and carbon dioxide into biochemical energy. These researchers use genetic engineering, analysis, and material science to turn that energy into opportunity.

Food, fertilizer, fuel, pollutant filter —the uses for algae are as diverse as the creative minds studying the organisms every day at the National Renewable Energy Laboratory (NREL). Algae abound in all parts of the world, ranging in size from single-celled organisms to dense forests of kelp.

The more NREL researchers study algae, the clearer their energy potential becomes. Algae grow rapidly, can be farmed in all 50 states, thrive in the open ocean, and turn sunlight and carbon dioxide into biochemical energy. Together, these attributes could enable industry to craft sustainable bioplastics and an estimated 5 billion gallons of low-carbon fuel annually in the United States.

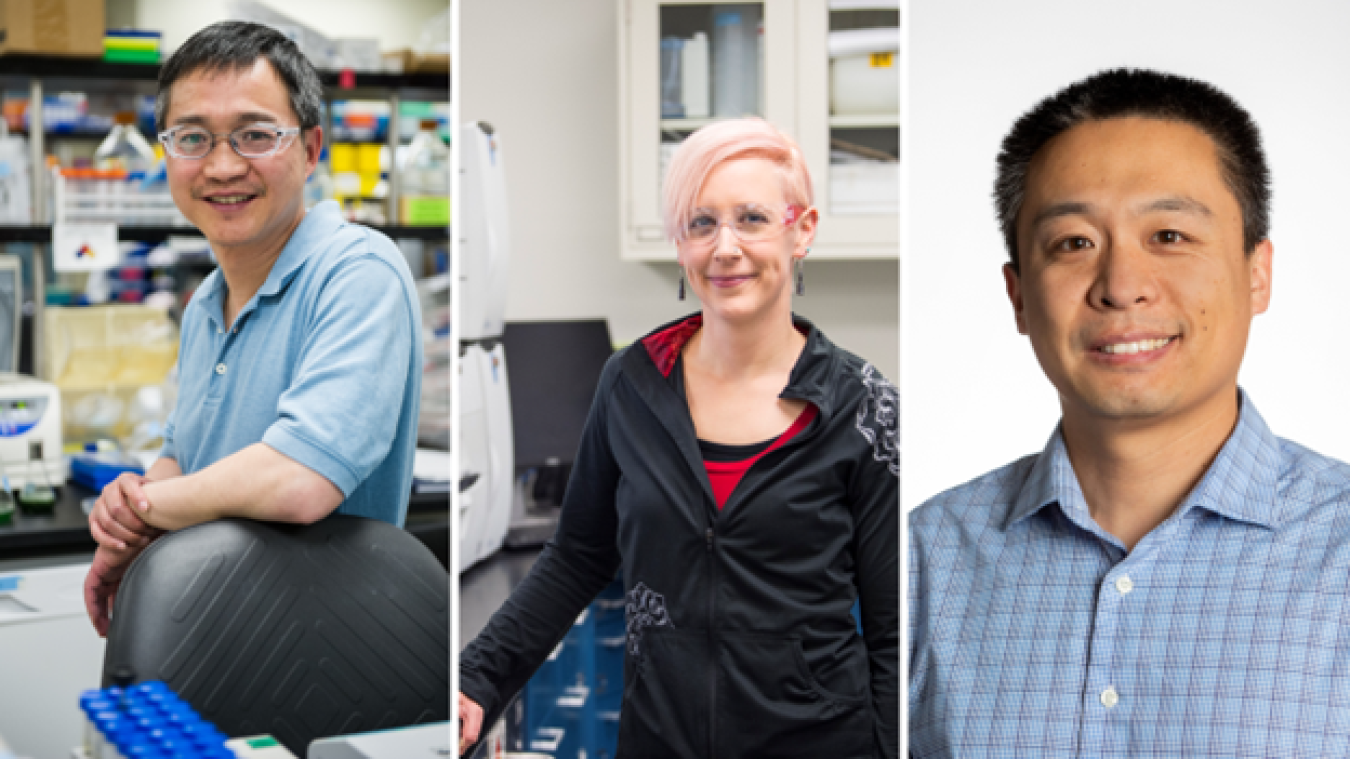

Still, targeted advances are needed to help algal fuels and bioproducts break into the wider commercial market. With support from the U.S. Department of Energy Bioenergy Technologies Office (BETO), NREL researchers Jianping Yu, Stefanie Van Wychen, and Tao Dong are using scientific and analytical tools to unlock the energy potential of algae.

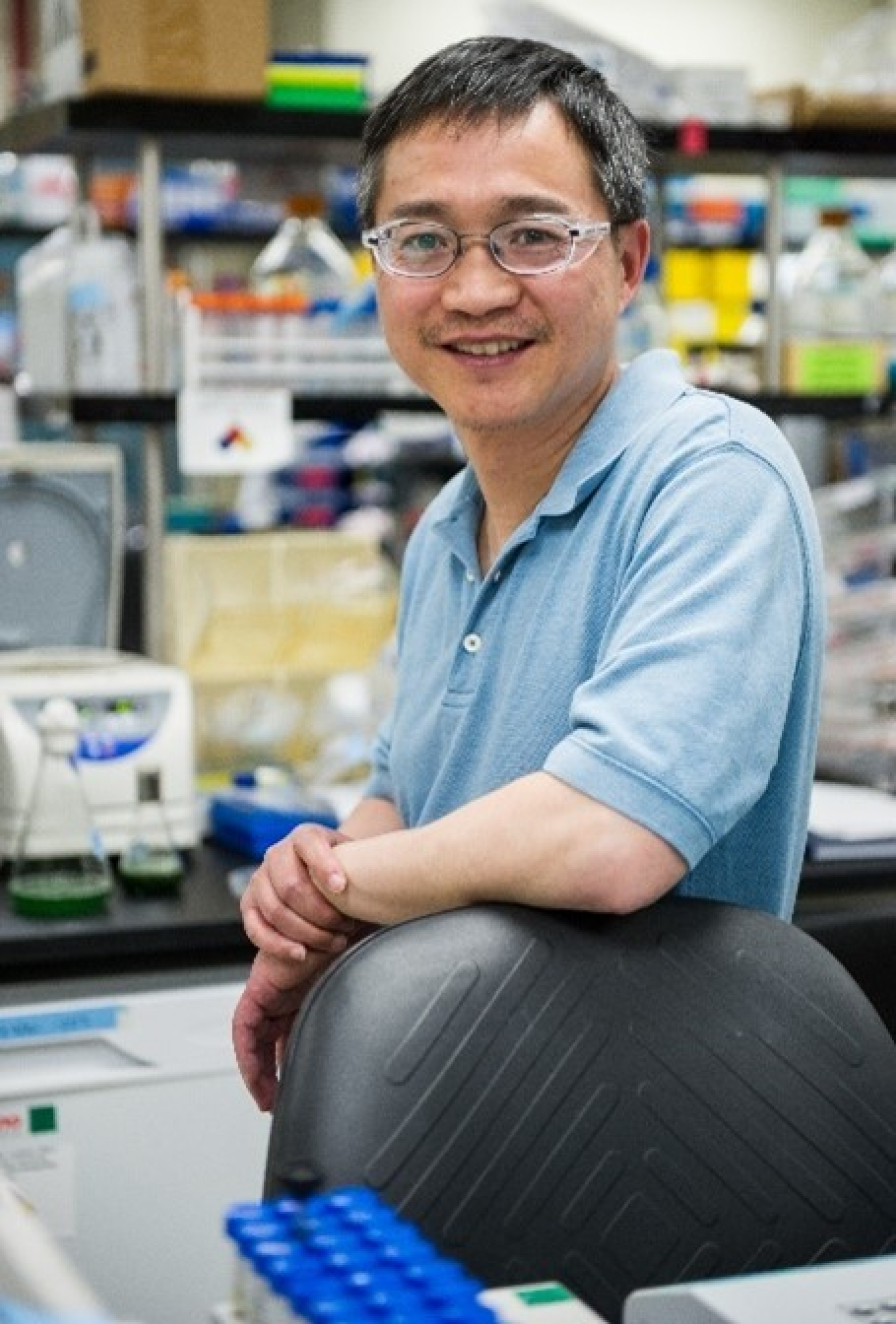

Jianping Yu: Asking More from Sun-Loving Cyanobacteria

What drew you to researching microalgae? When I was a college student dissecting frogs and fish, I found doing that was not for me. I did not enjoy killing animals, so I decided to study plants instead. What's most interesting about plants is their ability to photosynthesize. When I was a doctoral student at Michigan State University, I was introduced to a model cyanobacterium that we can study with the tools of genetics to understand photosynthesis. After I got some experience, I came to NREL and started to use cyanobacteria for hydrogen production and other uses.

What is NREL’s cyanobacteria photosynthetic energy platform? What challenge are you trying to address?

I am trying to use cyanobacteria to address a fundamental question in energy efficiency. Cyanobacteria convert solar energy to energy stored in carbon–carbon bonds. But they do this at low efficiency. Most energy from sunlight is lost along the way.

My hypothesis is that energy is dissipated during metabolism so the organism can survive rapidly changing environmental conditions like light intensity, nutrient supply, and temperature. They need a mechanism to rapidly dissipate energy so they don’t get burned.

We have shown that there are a couple mechanisms where cells synthesize carbon compounds such as glycogen, which is similar to starch. Cyanobacteria make and then degrade glycogen all the time in the background and the net result is adenosine triphosphate, or ATP—energy is dissipated.

So, manipulating the glycogen cycle, as we show in a recent study in Frontiers in Microbiology, leads to faster growth and improved photosynthesis. The potential in energy conversion from sunlight could be two or three times higher by improving energy metabolism such as the glycogen cycle.

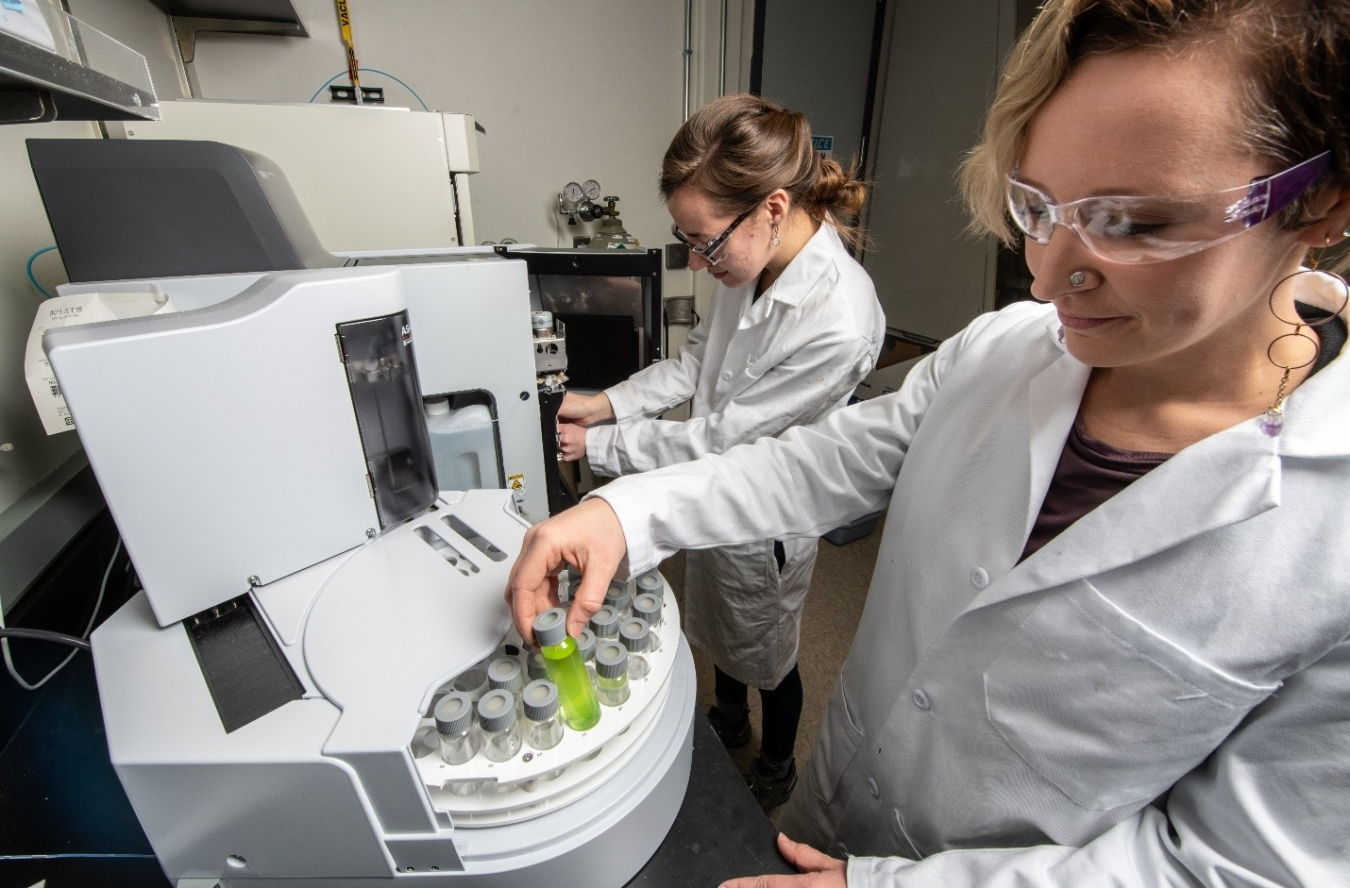

Stefanie Van Wychen: Counting Algal Carbs—and so Much More

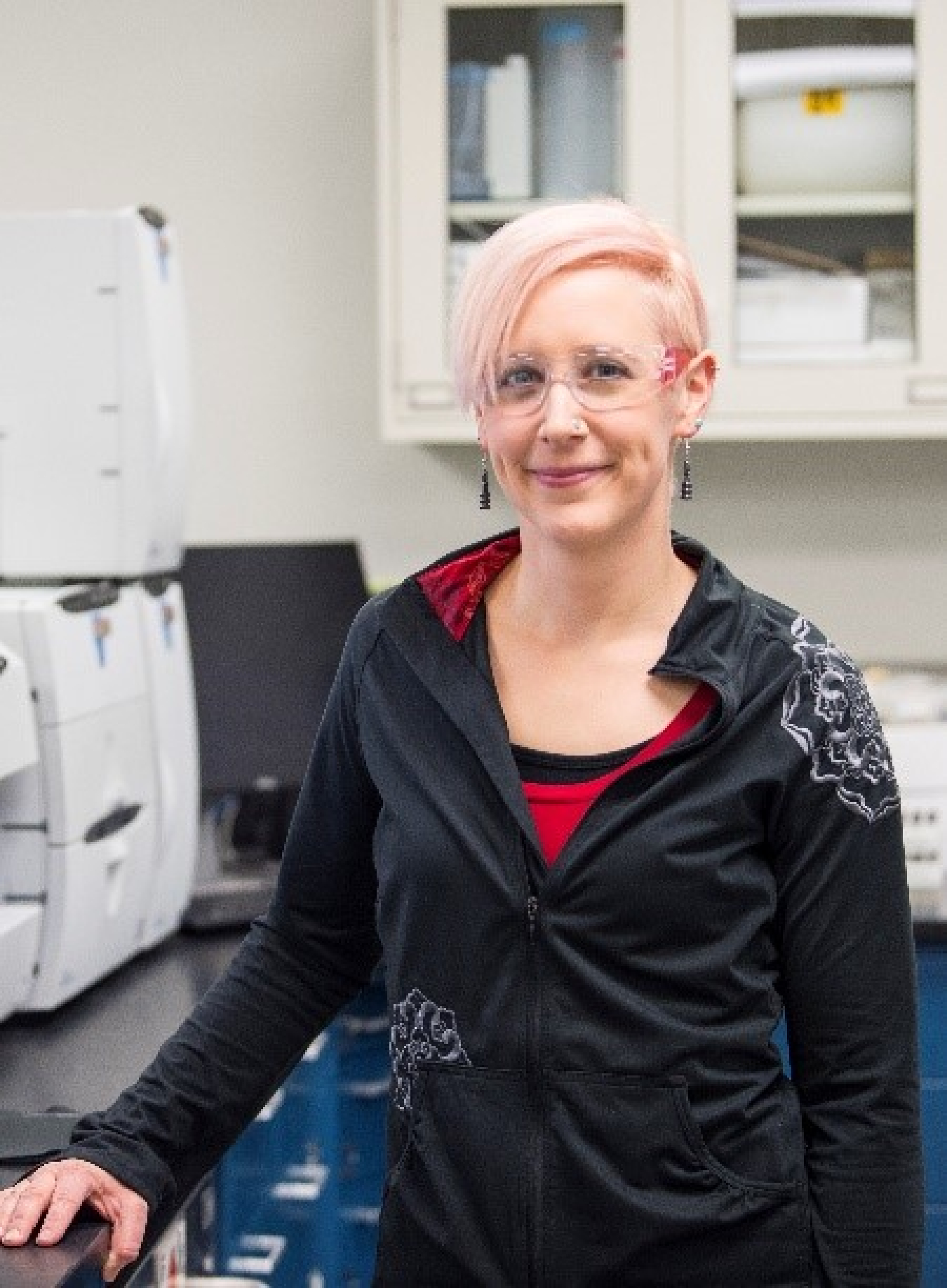

Results Are In—NREL publishes laboratory analytical procedures to provide validated methods for biofuels and pyrolysis bio-oils research, providing data essential for helping the algae industry fine tune its processes. Photo by Dennis Schroeder, NREL

Your NREL career has focused on analysis and characterization of algae and other kinds of biomass. How did you get here?

I did an undergrad and a graduate degree—in soil science and precision agriculture. Then I was hired on as a research associate working in irrigation management in eastern Colorado. After my university experience, I worked in drinking and surface water quality. Throughout my studies and professional experience, analytical chemistry was always a river that was flowing through in the background. I met a friend who worked at NREL and suggested I might like working here. There was a position on a team doing analytical chemistry work and I applied and joined. I really wanted to move back into research similar to what I had been doing during my graduate degree.

What is combined algal processing, also known as “CAP”? At a high level, what challenge is NREL trying to address?

CAP is looking for an integrated approach to maximizing fuel and chemicals production from algae that have different compositions—whether they're high protein, high carbohydrate, or high lipid.

We are looking at those compositions and then optimizing the process to utilize as many of the bio-components as we can. A process might begin with a dilute acid pretreatment that releases sugars. Then, that's usually followed by an extraction step to pull out the lipids, or fats to make the fuels and bioplastics. That typically leaves a protein-rich cake that can serve as a food or feed ingredient.

Each one of those steps produces something that can go toward a fuel or a value-added product. CAP is really about integrating all of those processes together into one biorefinery pathway. We’ve developed it for microalgae and now we're applying the concept to macroalgae as we move into projects with seaweed and sargassum.

What is your biggest research priority for making algae viable at the commercial level?

We need to develop and hone our analytical characterization methods to really identify all the potential fuels and products. The laboratory analytical procedures, developed at NREL and available to the public, have been really helpful to industry for quantifying fats, proteins, and carbohydrates so that they can make good decisions about their products and processes. A big focus at NREL and our group is really harmonizing the use of these methods across industry and academic research institutions so that we all kind of speak the same language.

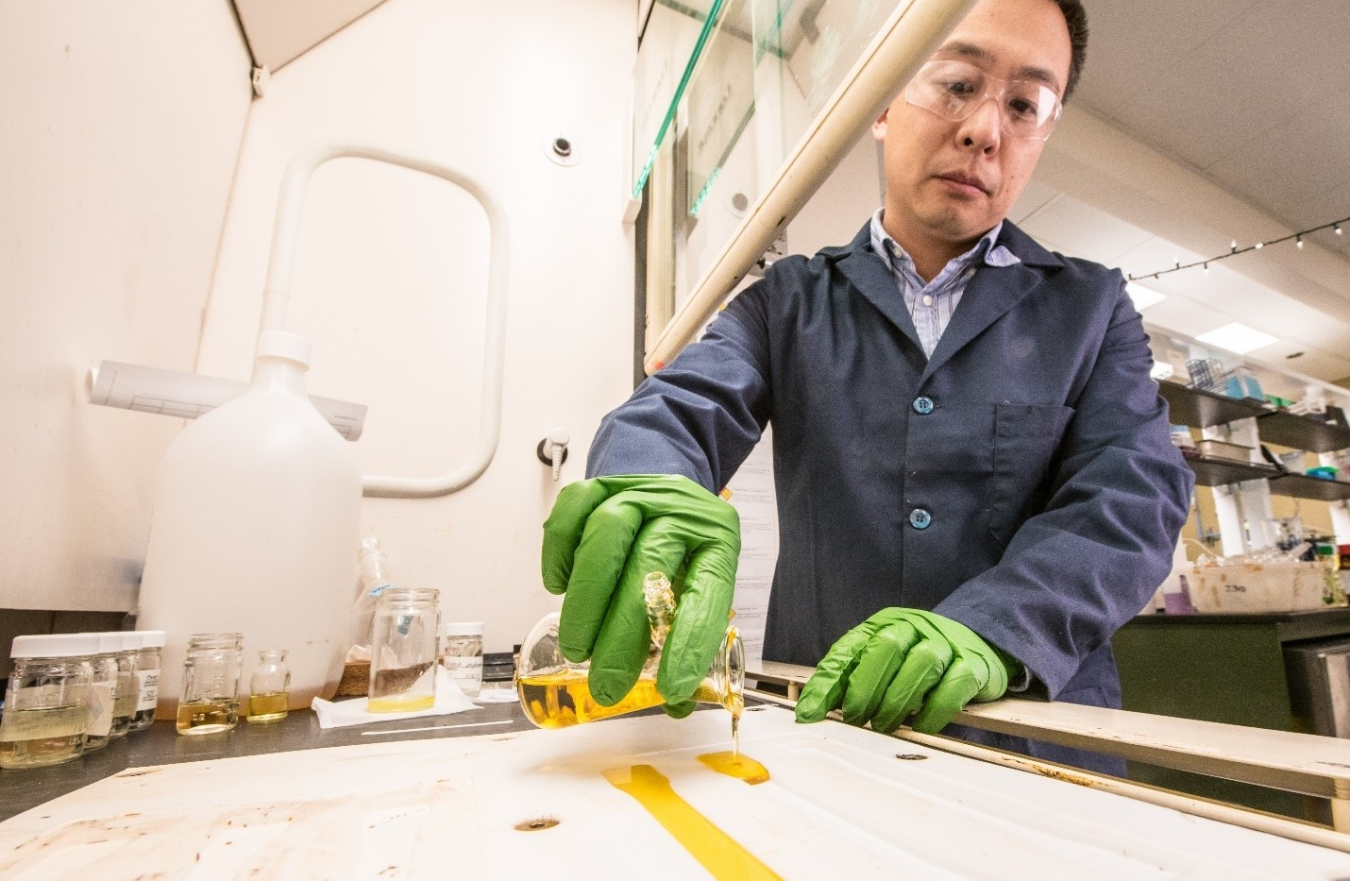

Tao Dong: Taking the Toxic out of Polyurethane with Algae

What steps in your career led you to studying algae?

Algae produce biomass that can be cultivated as a versatile crop with potential uses in both food and energy production, much like soybeans and corn. I have a research background in food science and biological systems engineering, with a focus on exploring ways to fractionate and convert biomass into different products. NREL’s algal biorefinery project has been an ideal career path for me. For decades, terrestrial agricultural refineries have been developed and engineered to produce a variety of agricultural products for food, chemicals, and fuels. Here at NREL, we are building on this tradition by leveraging existing technologies and developing new concepts to refine microalgae into fuels and value-added chemicals for different market sectors.

What drew you to researching microalgae?

When I was a college student dissecting frogs and fish, I found doing that was not for me. I did not enjoy killing animals, so I decided to study plants instead.

What's most interesting about plants is their ability to photosynthesize. When I was a doctoral student at Michigan State University, I was introduced to a model cyanobacterium that we can study with the tools of genetics to understand photosynthesis. After I got some experience, I came to NREL and started to use cyanobacteria for hydrogen production and other uses.

Polyurethane is a versatile material that has been used in our daily lives for building insulation, car seats, furniture, footwear, and more. However, the production of polyurethane involves toxic isocyanate, which can cause respiratory problems and has been classified as a potential carcinogen. The application of isocyanate has been strictly regulated to protect workers from health hazards.

And NREL is working on making these non-isocyanate polymers from algae?

Yes, we have developed algae-based NIPU products such as NIPU foam. We have identified that algal lipids, which have high content of polyunsaturated fatty acids, are preferred feedstocks for NIPU foam production regarding reactivity. We have demonstrated the production of algae-based NIPU foams, and we have been characterizing them in terms of tensile strength and thermal conductivity for a wide range of applications and to determine the value of these products in the current market.

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.