INL researchers have demonstrated that microalgae can be successfully stored for up to six months without the added energy costs of drying.

September 18, 2019

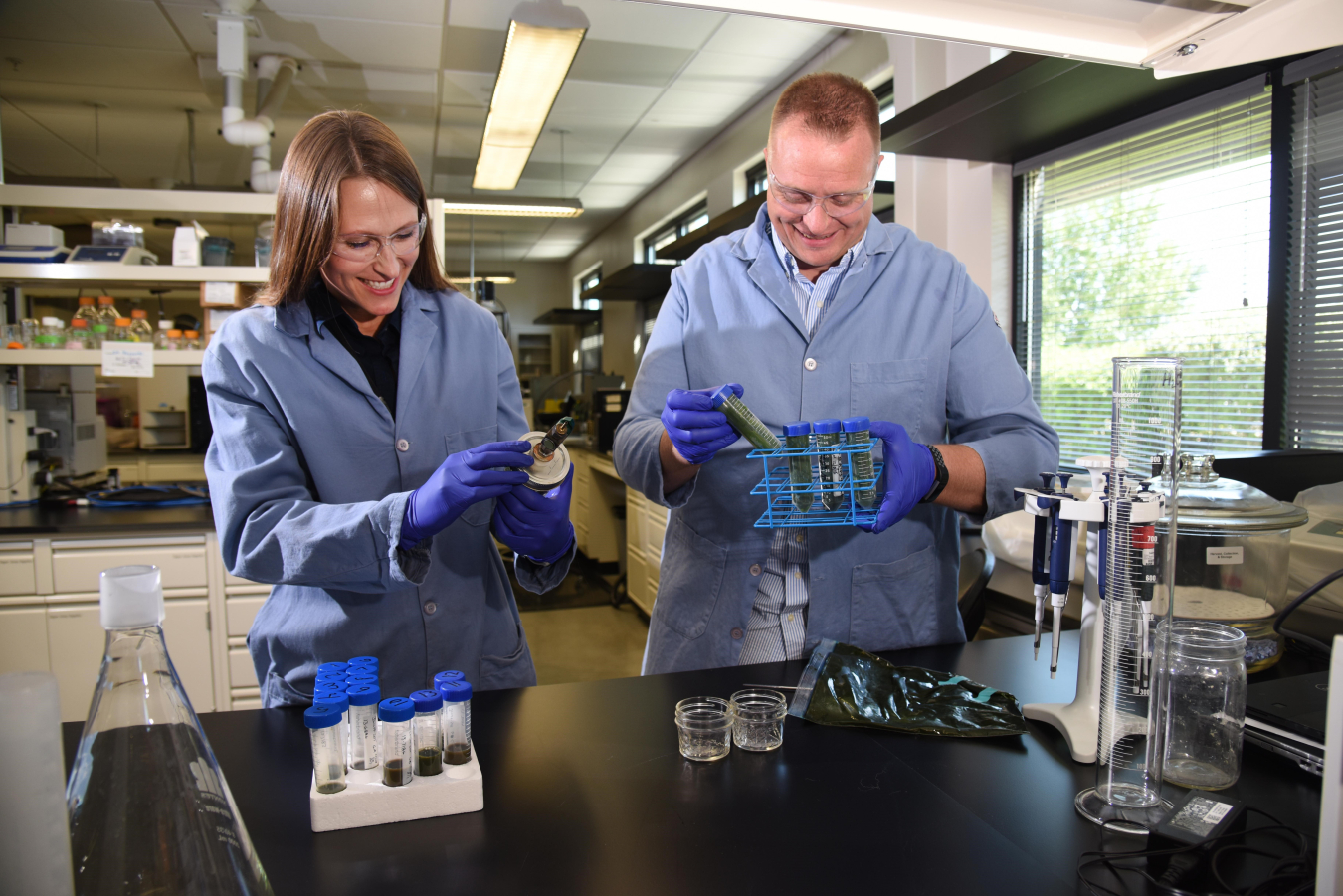

INL researchers have developed a cutting-edge storage technique for storing microalgae based on an age-old agricultural practice called ensiling. The technique can successfully store algae for up to six months without drying. Photo courtesy of INL.

Microalgae holds tremendous promise for the bioenergy industry.

Idaho National Laboratory (INL) researchers have demonstrated that microalgae can be successfully stored for up to six months without the added energy costs of drying.

The cutting-edge storage method is based on an age-old agricultural practice called ensiling. Ensiling is traditionally used to preserve animal feed. Ensiling typically involves storing biomass in belowground, wet storage pits that are covered to reduce exposure to oxygen.

The results of the demonstration, “Assessing the stability and techno-economic implications for wet storage of harvested microalgae to manage seasonal variability,” appeared in the journal Biotechnology for Biofuels in January 2019.

The Problems with Winter Production of Microalgae

Microalgae is an energy-dense microorganism that thrives on human sources of waste, such as agricultural runoff, and could be used to clean water while also serving as a source of biomass for conversion to biofuels.

But microalgae require ample sunlight for growth, meaning that algae production wanes during the winter months. It remains an industry imperative to develop effective long-term algae storage to offset times of decreased production—like winter—so that conversion facilities can intake level supplies of algal biomass throughout the year.

The ability to produce a surplus of algae during the summer and store it for winter would help make biomass conversion facilities more reliable and cost effective, which could mean better fuel prices for the consumer. Storage would also allow algae production in more northerly latitudes.

INL's Anaerobic Storage Technique Allows for Year-Round Microalgae Production

INL's microalgae storage technique addresses the challenge of seasonal variability in algae production, allowing conversion facilities to operate year-round.

To store the microalgae, researchers made a slurry the consistency of toothpaste consisting of 20% solids and 80% water. They then stored the slurry under anaerobic conditions, similar to the ensiling method.

In the absence of oxygen, bacteria present within the slurry are induced to produce lactic acid that preserves the biomass. Researchers found that dry matter losses over 30 days ranged from only 2.8% to 15.5%, with minimal additional losses recorded for up to six months.

Since ensiling is well-understood in the agricultural industry, the barrier to entry for agricultural producers would be minimal.

Cost Savings of INL's Microalgae Storage Technique

In the techno-economic analysis performed by the National Renewable Energy Laboratory, researchers estimate that ensiling algal biomass could result in significant cost savings.

Current storage techniques for microalgae rely on drying the biomass in a dryer and storing the material in aboveground carbon-steel storage vessels. The ensiling process saves energy because it eliminates the need for feedstock drying.

Considering the cost of growing, harvesting, and converting algae into biofuels, dry storage results in a minimum fuel selling price (MFSP) of $3.72/gallon gasoline equivalent (GGE). The wet storage (ensiling) scenario described here translates to an MFSP of $3.40/GGE, assuming a mature bioenergy industry.

By providing lower-cost options for long-term algae storage, researchers have alleviated seasonal supply shortages for conversion facilities, reduced the risk for industry, and encouraged outside investment making it more likely that cost-competitive algal biofuels will become a part of the U.S. bioeconomy.

Next Steps for the Research Team

Researchers plan to apply this technology to new algae strains and different algae cultivation practices while also looking at algae metabolism and trying to understand which bacteria are beneficial for storage.

For more information, visit:

- Bioenergy Technologies Office 2019 Peer Review Presentation Slides

- Journal Article

J. Richard Hess

J. Richard Hess is Director of the EERE Program Office at Idaho National Laboratory (INL) and serves as the Laboratory Relationship Manager to the U.S. Department of Energy’s (DOE’s) Bioenergy Technologies Office. He oversees and leads development of strategic planning between the Energy and Environment Science and Technology (EES&T) directorate and DOE EERE to ensure highly impactful, integrated, and objective-driven EERE programs at INL. Richard has experience managing INL’s Bioenergy Program, which focuses on the cost-effective use of lignocellulosic crop residues in biorefining operations.