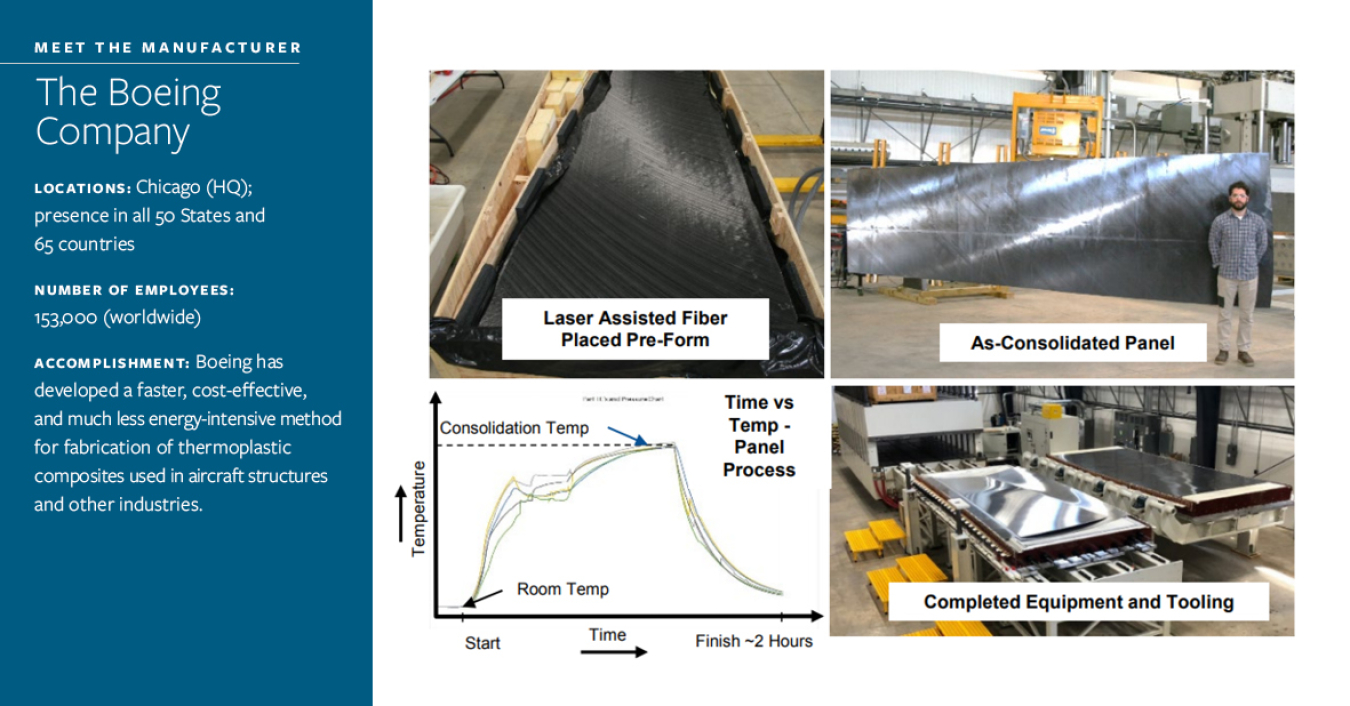

Images courtesy Boeing Industries

The Boeing Company, through its central research and development organization Boeing Research & Technology (BR&T), has successfully demonstrated a method for consolidation and molding of thermoplastic composites in complex components with a processing time of less than 60 minutes and a whopping 80% reduction in energy consumption compared to current manufacturing systems such as autoclave processing of thermoset materials. Working with partner companies Cytec (now part of Solvay), Temper, Inc., and Ajax TOCCO under a DOE grant, BR&T developed a scale-up fabrication system that allows for an accelerated production rate of airplanes. This processing technology has broad application outside the aerospace industry to include automotive, heavy trucking, marine, and wind energy.