More and more manufacturers are looking at investments in energy efficiency at their industrial facilities and throughout their supply chains...

Advanced Manufacturing & Industrial Decarbonization

June 27, 2019More and more manufacturers are looking at investments in energy efficiency at their industrial facilities and throughout their supply chains as a means to reduce costs and meet sustainability goals. To remain competitive, manufacturers at every point in the chain are pursuing proficiency in energy management to better meet the needs of their industrial customers, local communities, and final product consumers.

Unlike one-off energy projects that may produce a temporary bump in energy savings, programs aligned with ISO 50001 sustain and continuously build savings. (Photo: Pixabay)

The Commission for Environmental Protection (CEC) recently published Supply Chain Energy Efficiency through ISO 50001: A How-to Guide for Your Company. This free guide covers each step in the process to establish a robust energy management system (EnMS) aligned with the ISO 50001 standard across a company’s supply chain. ISO 50001 is an internationally recognized and proven approach to continuously improve energy performance.

To produce this guide, an industry expert drew from a three-year CEC project that gathered input from supply chain and energy efficiency professionals in the relevant energy agencies of Canada, Mexico, and the United States. Natural Resources Canada, the Comisión Nacional para el Uso Eficiente de la Energía, and the U.S. Department of Energy (DOE) contributed useful insights and best practices for boosting energy performance along the supply chain—whatever the starting EnMS expertise or experience of each supplier.

Broad and practical DOE support for the ISO 50001 standard makes it easy for original equipment manufacturers to help their suppliers or facilities across U.S. industry get the training, tools, and guidance they need to achieve, sustain, and continuously grow energy savings, improve the bottom line, and gain recognition or certification. The guide draws heavily from DOE’s proven programs and resources, including the following:

- 50001 Ready: A self-guided approach to help facilities establish an EnMS and self-attest to the structure of ISO 50001, making them eligible for formal DOE recognition.

- Superior Energy Performance 50001 (SEP 50001): Facilities and organizations that achieve sustained excellence in their EnMS may earn certification to the SEP 50001 program (includes ISO 50001 certification) and gain elevated DOE recognition using the SEP 50001 Scorecard.

- 50001-Certified Practitioners in EnMS: Professionals who work within an organization or with clients to establish and/or maintain an EnMS aligned with ISO 50001 can obtain specialized EnMS training and recognized qualification.

- Free Online Software Tools:

- 50001 Ready Navigator: Helps users set up and maintain an EnMS to the best practices of the ISO 50001 global standard.

- Energy Footprint Tool: Helps manufacturing facilities track their energy consumption, factors related to energy use, and significant energy end-use.

- Energy Performance Indicator Lite: Uses regression-based analysis to help establish a normalized baseline of energy consumption and track annual progress of improvements, energy savings, and performance indicators.

- Case studies: Relates the experiences of companies that successfully used DOE resources to implement ISO 50001 through 50001 Ready and/or SEP.

Check out the Supply Chain Energy Efficiency through ISO 50001: A How-to Guide for Your Company and start your supply chain on the road to sustained energy savings in alignment with ISO 50001!

50001 Ready and SEP 50001 are managed by DOE’s Advanced Manufacturing Office (AMO) within the Office of Energy Efficiency and Renewable Energy. Both programs complement DOE’s Better Buildings, Better Plants Program. AMO supports early-stage research to advance innovation in U.S. manufacturing and promote American economic growth and energy security.

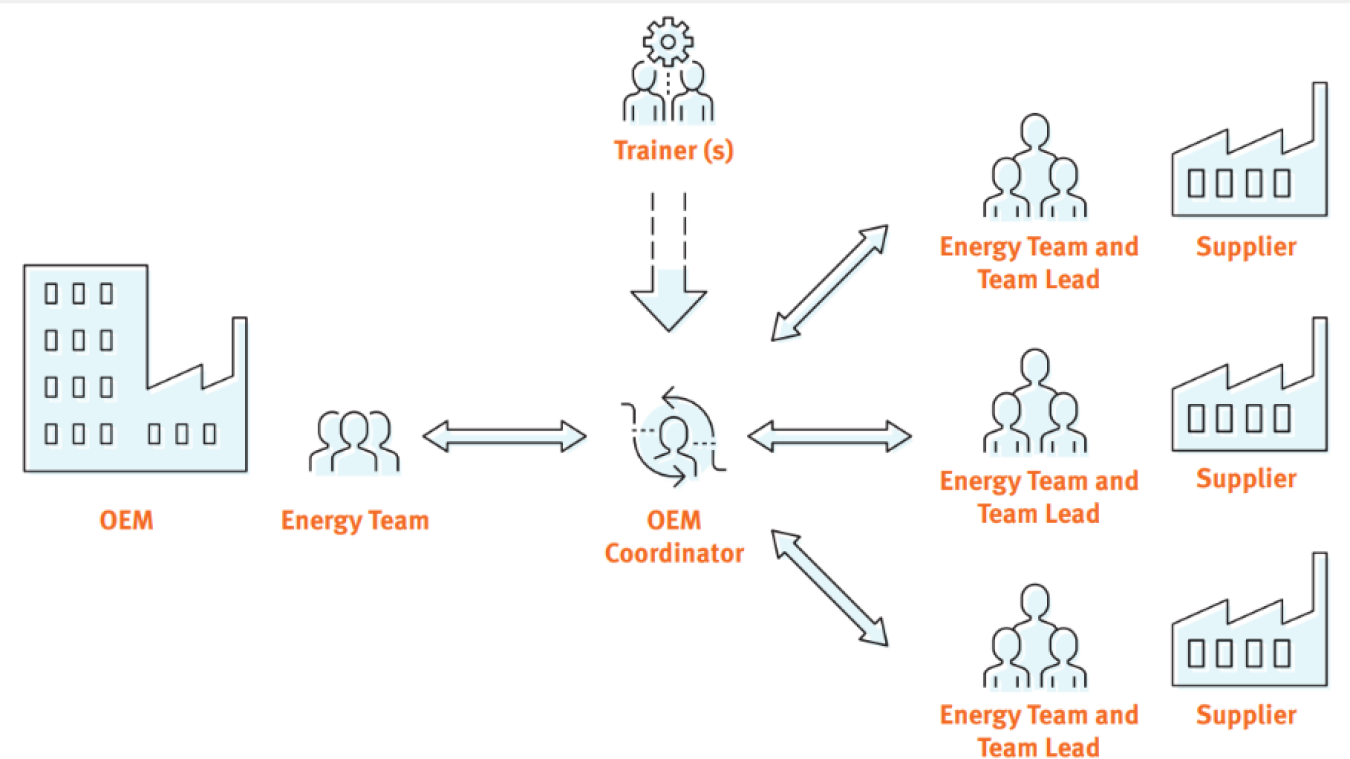

Using the new Supply Chain Guide, an OEM is well positioned to leverage ISO 50001 up the supply chain. (Source: CEC, May 2019. Supply Chain Energy Efficiency through ISO 50001.)