Office: Advanced Materials and Manufacturing Technologies Office (AMMTO)

FOA Number: DE-FOA-0003155

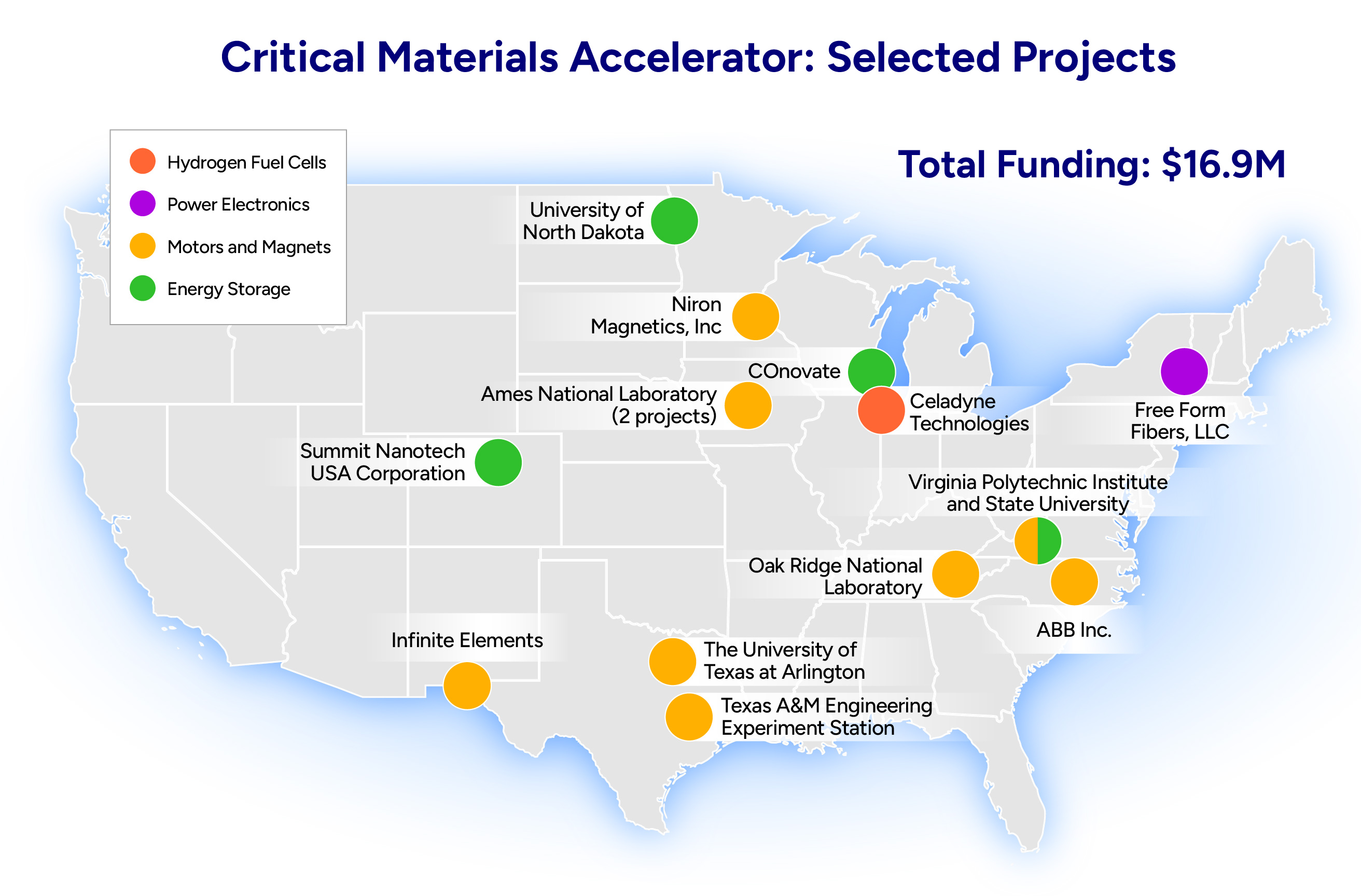

Funding Amount: $16,926,260

On Dec. 10, 2024, the U.S. Department of Energy's (DOE's) Advanced Materials and Manufacturing Technologies Office (AMMTO) announced 14 selections through its Critical Materials Accelerator program. The goal of this program is to validate technologies and processes proven on a small scale to accelerate commercial readiness and adoption.

Projects were selected for their potential to:

- Foster industry partnerships to prototype and pilot technologies and processes proven at the bench scale to accelerate innovative solutions that address critical materials challenges in high-impact areas.

- Validate the materials and manufacturing technologies that reduce demand or extend the lifetime of critical materials.

- Enable informed decisions, optimize processes, and build confidence in technology scale up through life cycle assessment (LCA) and techno-economic analysis (TEA).

- Address the urgency to meet critical material demand with secure and sustainable critical material manufacturing technologies.

The selected projects will address critical materials challenges in high-impact energy supply chains, including hydrogen fuel cells; semiconductors for electric vehicles, wind, and solar; magnets for wind turbines and motors; batteries; and motor design.

DOE selected 14 projects at institutions across the United States (in Colorado, Iowa, Minnesota, New Mexico, New York, North Carolina, North Dakota, Tennessee, Texas, Virginia, Wisconsin) to receive funding through its Critical Materials Accelerator program. The program helps to validate small-scale technologies and processes for commercial readiness and adoption.

DOE selected 14 projects at institutions across the United States (in Colorado, Iowa, Minnesota, New Mexico, New York, North Carolina, North Dakota, Tennessee, Texas, Virginia, Wisconsin) to receive funding through its Critical Materials Accelerator program. The program helps to validate small-scale technologies and processes for commercial readiness and adoption.

Explore the Selected Projects

Project: Low Iridium and Platinum Loading Membrane Electrode Assemblies for Electrolysis

Project Partner: Argonne National Laboratory

Location: Chicago, Illinois

Federal Funding: $1,000,000

Celadyne Technologies aims to develop catalyst formulations that pair with a thin low-resistance proton exchange membrane for hydrogen devices—membranes that use 72% less platinum and iridium and 92% less fluorine than state-of-the-art membranes. The membrane, called Dura™, was developed as a gas-impermeable hydrocarbon layer in a bilayer architecture using DOE SBIR funding. Developing a catalyst to use in conjunction with the Dura membrane will enable high-current density electrolyzer operation with low critical material demand and reduced hydrogen crossover for fuel cells.

Project: A New Approach to Manufacturing High Purity, Low Environmental Impact Silicon Carbide Feedstock for High Power Semiconductor Chip Technology

Project Partners: Pennsylvania State University, State University of New York at Stony Brook, Argonne National Laboratory

Location: Saratoga Springs, New York

Federal Funding: $925,898

Free Form Fibers seeks to create a novel approach to producing silicon carbide (SiC), a vital component of semiconductors. By using a laser-driven chemical vapor deposition (LCVD) technology, Free Form Fibers can deliver a low-defect, high-purity SiC raw material product for use in physical vapor transport manufacturing that will result in high production yields for SiC boules because of the reduced contamination and defects. This technique has a significantly reduced energy consumption and greenhouse gas emission footprint, compared to the traditional SiC powder-making process. The project looks to validate the use of a sustainable process to fulfill the domestic need of pure SiC powder to produce high-yield, low-defect SiC wafers and decrease manufacturing costs downstream.

Project: Pilot Demonstration of the GAME Technology To Boost Critical Mineral Production

Project Partners: Phinix LLC, Rio Tinto, University of Kentucky

Location: Blacksburg, Virginia

Federal Funding: $1,000,000

Virginia Polytechnic Institute and State University (Virginia Tech) intends to scale up its novel solvent extraction technology, which efficiently extracts metals of low concentrations using high aqueous to organic phase ratios. A prototype of the gas-assisted microbubble extraction (GAME) technology has been successfully fabricated and validated through benchtop batch testing. To achieve pilot scale success and move GAME’s technology readiness level to six, the project will utilize acid mine drainage generated from a copper mine, containing critical and valuable elements, most of which are present in low concentrations, as the primary feedstock. The project looks to produce critical materials with a minimum purity of 95% for neodymium, dysprosium, and yttrium, and 99.5% for nickel, cobalt, manganese, and copper.

Project: Recovery of Rare Earth Elements from e-Waste using Functionalized Mesoporous Carbon Foams

Project Partner: Oak Ridge National Laboratory

Location: College Station, Texas

Federal Funding: $1,280,553

Texas A&M University plans to develop a cost-effective and sustainable solid-phase extraction (SPE) method for rare earth elements (REEs) recovery from electronic waste (e-waste). SPE using crumpled graphene-balls-based porous membranes will be developed for neodymium, praseodymium, and dysprosium recovery. The project seeks to develop a novel synthetic approach of tripodal diglycolamide ligands with stronger REE affinity using simple, cheap, readily available chemicals in just four steps for enhanced scalability. It will also design self-supporting tripodal mesoporous carbon foams as stable and reusable adsorbents for REE recovery without requiring frequent extractant replacement or cleaning and develop a low-cost and scalable SPE method that eliminates the use of organic solvents in the REE separation process.

Project: High-Efficiency Industrial Motors Using U.S.-Sourced Non-Rare-Earth Permanent Magnets from Mining Byproducts

Project Partners: Powdermet Inc., Ames National Laboratory, North Carolina State University

Location: Cary, North Carolina

Federal Funding: $1,520,000

ABB Inc. aims to develop and prototype motors using manganese-bismuth (MnBi)-based polymer-bonded permanent magnet technology for general purpose and traction applications. If successful, this technology would eliminate the use of critical materials in industrial motors and non-drivetrain automotives, which account for 38% of the market combined and would lead to an opportunity for >10% market share adoption. The technology builds upon prior work funded by the government to develop a suitable non-REE magnetic material, which lowers the technical risk and improves efficiency and cost-effectiveness; and the motor topology selection is compatible with EV industry.

Project: Producing Silicon Anode Materials for Li-Ion Batteries

Project Partner: University of Idaho, Lattice Materials, Leonardite Production, Packet Digital

Location: Grand Forks, North Dakota

Federal Funding: $999,999

The University of North Dakoka (UND) will conduct a prototype demonstration of a proven process for producing low-cost, high-performance silicon monoxide with graphene coating (SiO/G) anode materials for lithium (Li)-ion batteries (LIBs) while reducing water, waste, chemical intensity, and energy consumption. The proposed work would achieve three key components needed for LIBs: 1) high-purity silicon scrap waste produced from semiconductor manufacturers; 2) innovative plasma-based SiO synthetic techniques, and 3) a unique graphene precursor – humic acid and UND’s patented technology for in-situ synthesis of graphene coated SiO anode. The prototype will be a key first step to establishing a domestic production facility for high-performance SiO anode materials to meet the increasing anode demands in the Li-ion battery industry. The outcome of the proposed work will be advancing the SiO/G process to technology readiness level 6 and preparing for pilot testing.

Project: Mechanically Robust High Magnetic Performance NdFeB Magnets with Resilience in Applications and Reduced Magnet Wastes

Project Partners: Noveon Magnetics Inc., University of Arizona

Location: Ames, Iowa

Federal Funding: $1,000,000

Ames National Laboratory and its partners will prototype and scale up the tough neodymium-iron-boron (NdFeB) magnet technology developed at the Critical Materials Innovation Hub (CMI Hub). The technology aims to improve manufacturing efficiency by enhancing the magnet’s mechanical toughness, which in turn reduces the failure rate when machining the blocks into parts, especially those with complex geometries. The technology has been successfully demonstrated at the bench scale (TRL 3) with mechanical and magnetic performance superior to the baseline commercial products and this project aims to accelerate it to pre-pilot scale (TRL 6). Improving the magnet’s strength, reducing waste production and machining failure rate, increasing the magnet’s service life, and making it easier to recycle the magnets will directly lead to savings in the critical materials required to make the traditional NdFeB sintered magnets. The technology was recognized with a 2021 R&D 100 Award. Two patent applications were submitted to the USPTO.

Project: Pre-Pilot Production of High-Performance Magnets Based on the Cost-Effective Mountain Pass Mischmetal with Reduced Critical Materials Content

Project Partners: MP Materials, Ames National Laboratory

Location: Arlington, Texas

Federal Funding: $1,000,000

The University of Texas at Arlington seeks to scale up production of a NdFeB magnet with partial substitution of neodymium and praseodymium with cerium and lanthanum, using a sintering aid. This project will not only reduce the use of critical REE in a permanent magnet by 30 to 40%, but it will also eliminate the need for dysprosium and achieve an increased energy product. By enabling the industry partner to scale the process for mass production, this project will ultimately accelerate the scale-up of domestic magnet manufacturing. The technology is based on LaCe-containing NdFeB magnets developed at the Critical Materials Innovation Hub.

Project: A Novel Energy-Efficiency Scalable Membrane Process for Separation and Recovery of Rare Earth and Domestic Sources

Project Partner: North Carolina Agricultural and Technical State University

Location: Oak Ridge, Tennessee

Federal Funding: $1,000,000

Oak Ridge National Laboratory aims to develop an energy-efficient, cost-effective, high-yield and environmentally friendly integrated process for separation and recovery of high-purity rare earth elements (REEs) from domestic waste stream sources and mining tailings. This will be performed using a single-step integrated membrane solvent extraction process, based on the concept of using low-cost, robust membrane supports for solvent extraction. By reducing the number of stages involved in solvent extraction, this process offers a small overall footprint with linear scalability and can achieve high extraction rates of REEs from unconventional feedstocks while maintaining low energy and cost requirements. If successful, the project will demonstrate separation and recovery of REEs with >99.5% purity and >90% yield from domestic mine tailings and waste streams, as well as successful separation of heavy REEs from the resulting product of mixed REEs.

Project: Accelerate Validation of a Domestic, Sustainable Alternative for Battery Grade Graphite in Lithium-Ion Batteries

Project Partners: Pacific Industrial Development Corporation, XALT Energy, Applied Catalyst, Argonne National Laboratory

Location: Wauwatosa, Wisconsin

Federal Funding: $1,000,000

COnovate intends to build on bench-scale success of developing and patenting an eCOphite active anode material to replace graphite in lithium-ion batteries (LIBs). The material permits higher lithium capacity compared to graphite, leading to an increased energy density, it enables LIBs with faster charging, offers better low temperature performance, and cycles safer than industry-standard graphite-based LIBs. The project outlines a plan to reduce the amount of the battery-grade graphite needed per LIB anode, from at least 25% up to 100% replacement, while meeting or exceeding 90% of baseline LIBs key performance indicators with material properties that are compatible with industrial battery manufacturing methods. The proposed work aims to bridge the current capability gap with the eCOphite technology by demonstrating the performance of LIBs with partial or full replacement of graphite at commercially relevant scales of battery formats and sizes.

Project: Enhancing Operational Efficiency in Direct Lithium Extraction through Advanced Water Recovery System

Project Partner: Albemarle Corporation

Location: Lafayette, Colorado

Federal Funding: $1,000,000

Summit Nanotech USA Corporation aims to enhance operational efficiency, lower energy consumption, and minimize the environmental footprint of the entire direct lithium extraction (DLE) process. Water demand is a key issue for lithium extraction, and the proposed work would efficiently recycle and reuse water, minimizing water consumption and environmental impact. The advanced electrochemical membrane separation that utilizes electrodialysis reversal has been validated at bench scales to achieve water purification and desalination rates with lower capital and operating costs than competing recovery systems. The process involves the transfer of lithium ions between solutions through ion-exchange membranes without reduced chemical intensity and without energy-intensive gas-producing reactions at the electrodes, which can limit concentration of feed. The goal of the work is to integrate the technology into DLE applications using real brine sourced directly from industry partner Albemarle’s Magnolia Facilities in the Smackover region.

Project: Critical Rare-Earths-Free Cerium Gap Magnets

Project Partners: TdVib LLC, HL Mechatronnics, Purdue University

Location: Ames, Iowa

Federal Funding: $1,000,000

Ames National Laboratory seeks to demonstrate a cost-competitive, one-step castable, grain-oriented, and fully dense cerium-based gap magnet. The project will focus on optimization of directional solidification necessary to achieve the target performance of an energy product of 15 MGOe. The project will scale up the process to fabricate the cerium-based gap magnet to produce 1 to 5 kg of material. Through these project objectives the team will deliver a fully dense anisotropic gap magnet that aims to satisfy needs for a wide range of middle-energy applications including steeper and micro motors, motors for drones, and electric vehicles. The background work for this technology won a R&D 100 Award and is patented.

Project: Techno-Economic and Life Cycle Assessment of Biohydrometallurgical Critical Mineral Recovery from E-Waste and Manufacturing Scrap

Project Partner: National Renewable Energy Laboratory

Location: El Paso, Texas

Federal Funding: $1,500,000

Infinite Elements aims to demonstrate a combination of bioleaching and advanced peptide design to efficiently recycle critical materials from electronic waste (e-waste). The project aims to increase critical material recovery yields from 45% to 85% while improving energy efficiency by more than 50%. The process includes three modules: dissolution, biofilter production, and refining. It is capable of handling diverse feedstocks of e-waste and can recover critical materials with an 80% reduction in emissions compared to conventional hydrometallurgy. If successful, the project would demonstrate a commercially viable project that could be used with a variety of waste streams to produce rare earth elements domestically.

Project: Variable Flux Field Intensifying Motors Using Iron Nitride Permanent Magnets

Project Partners: Illinois Institute of Technology, Oak Ridge National Laboratory

Location: Minneapolis, Minnesota

Federal Funding: $2,699,810

Niron Magnetics, Inc. will design, analyze, and fabricate a prototype permanent magnet motor without the use of critical rare earth materials. This technology will utilize Niron's variable flux field intensifying iron nitride permanent magnet material, with a potential for significant shift in the state-of-the-art for high-performance electric motors. If successful, the motors would demonstrate a 50% decrease in carbon dioxide as compared to a NdFeB-based motor and would increase the efficiency of the motor by 2% over the entire drive cycle.

Learn More and Get Involved

-

February 3, 2025

-

January 28, 2025

-

January 22, 2025

Get the latest in funding opportunities and selections for advanced materials and manufacturing.