The Breaking It Down series aims to inform and inspire people by putting advanced manufacturing technologies and processes into simpler terms.

Jump To

With electric vehicles (EVs) that get us places, cell phones that connect us to others, and utility-scale electric grid storage that powers our homes, batteries are all around us.

Batteries can be either mobile, like those in electric vehicles, or stationary, like those needed for utility-scale electricity grid storage.

As the nation transitions to a clean, renewables-powered electric grid, batteries will need to evolve to handle increased demand and provide improved performance in a sustainable way.

What Is a Battery Made of?

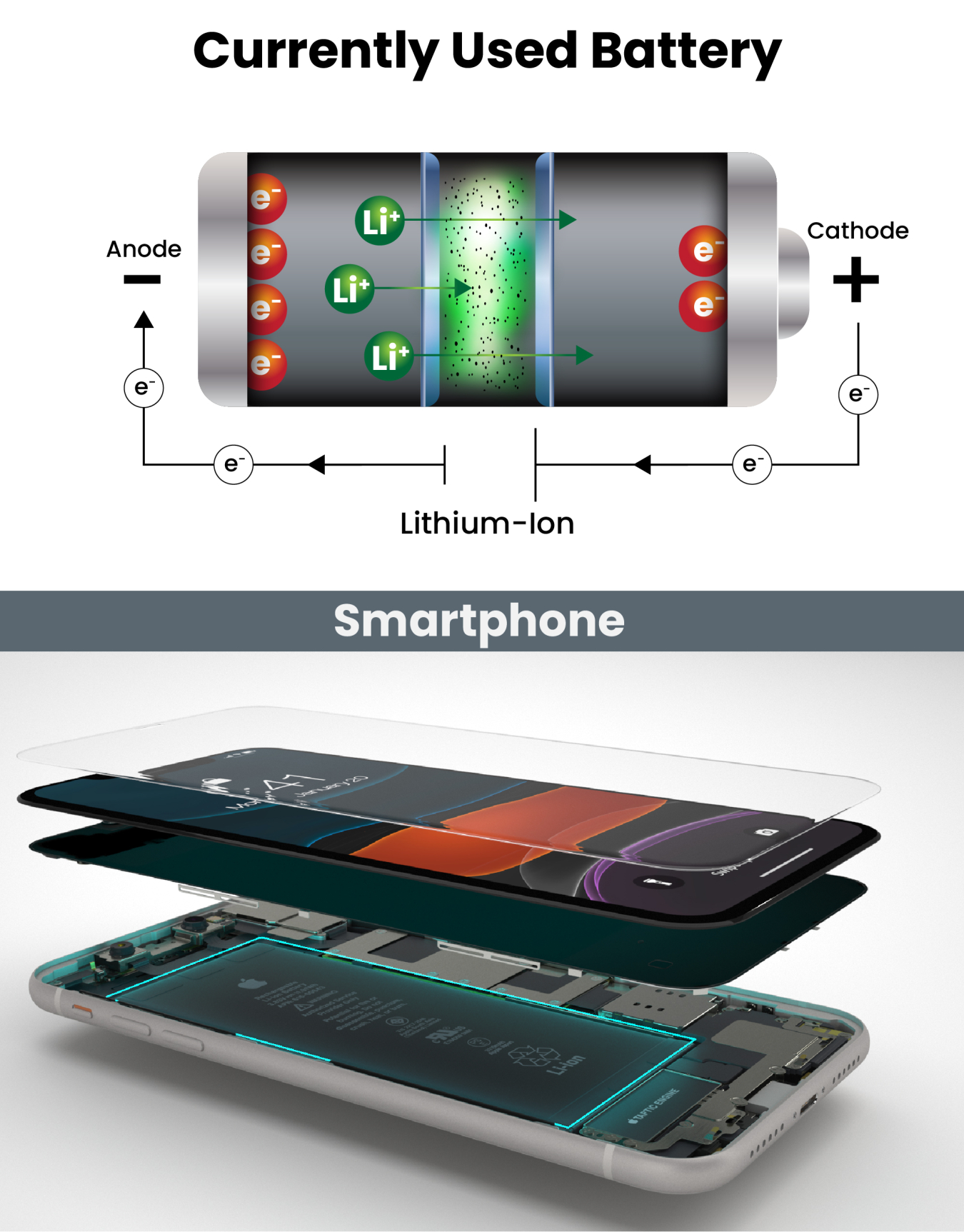

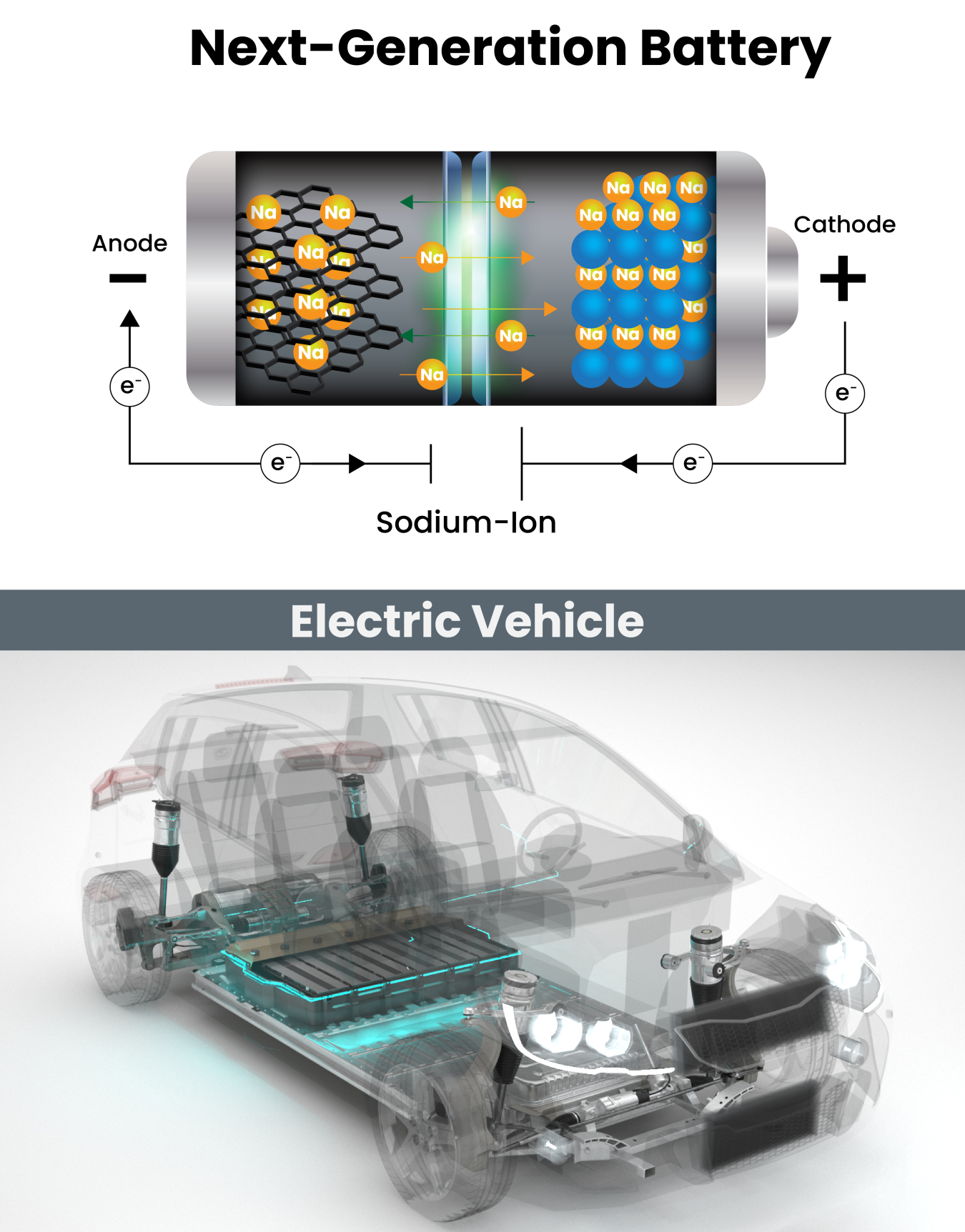

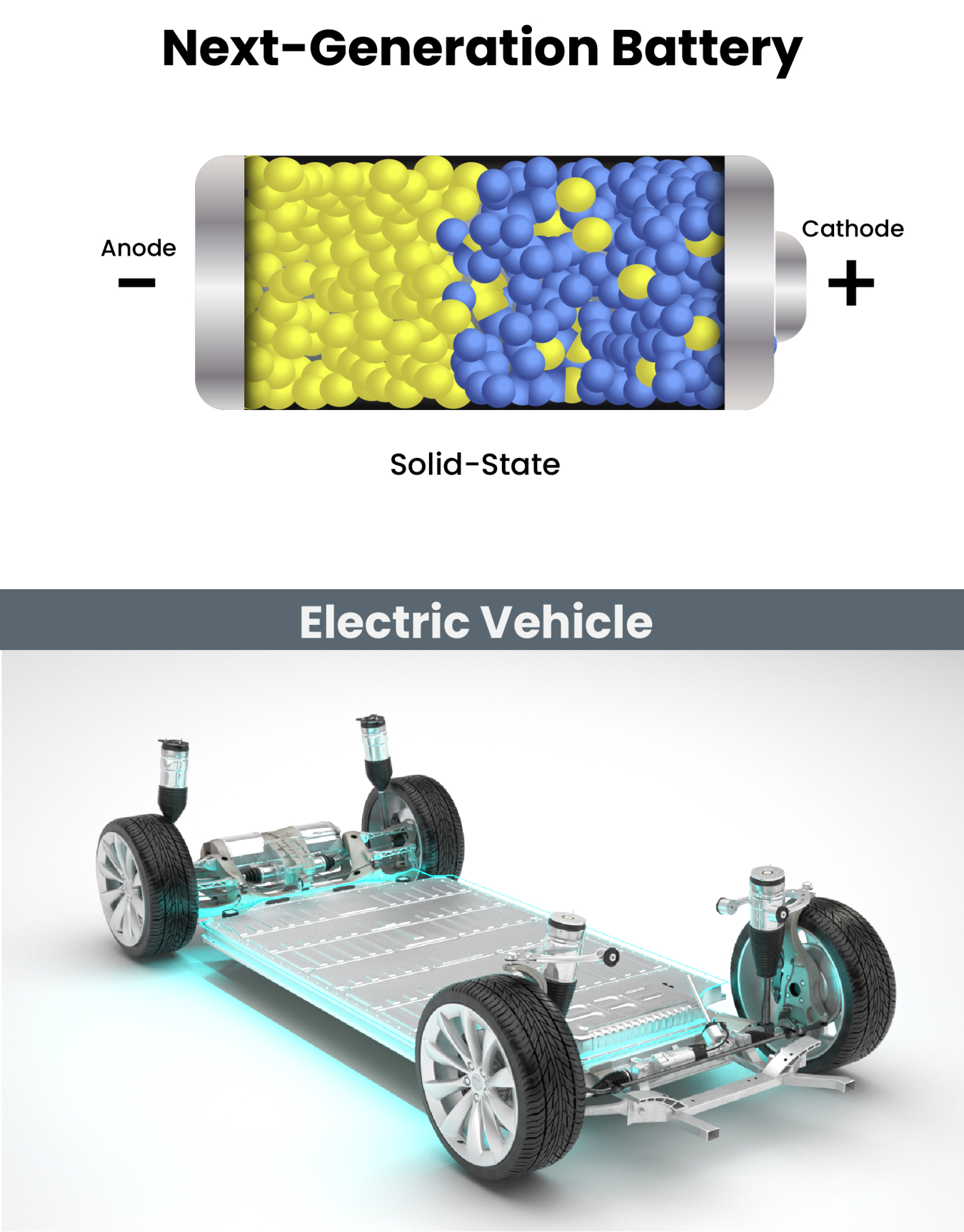

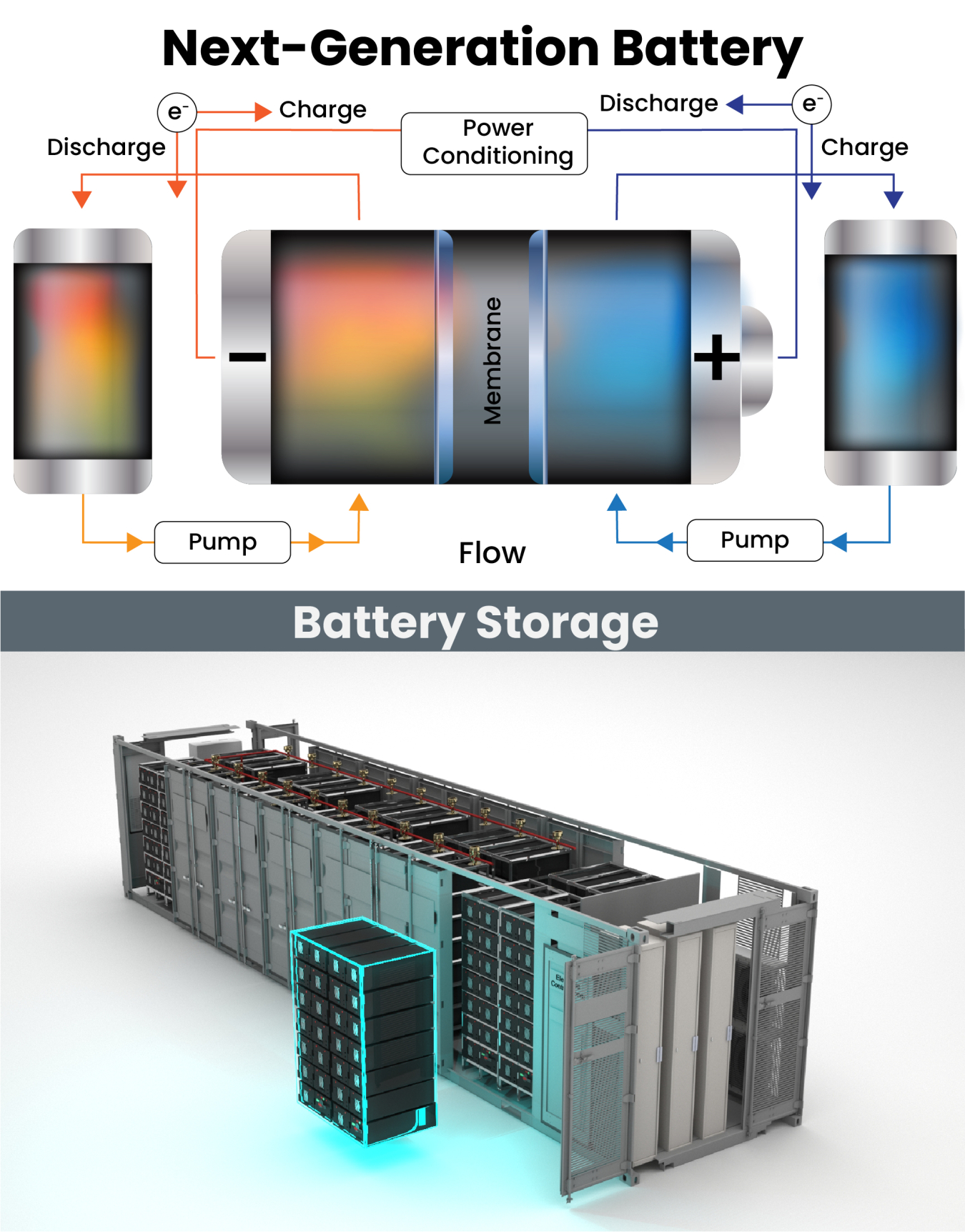

You’ve probably heard of lithium-ion (Li-ion) batteries, which currently power consumer electronics and EVs. But next-generation batteries—including flow batteries and solid-state—are proving to have additional benefits, such as improved performance (like lasting longer between each charge) and safety, as well as potential cost savings.

These next-generation batteries may also use different materials that purposely reduce or eliminate the use of critical materials, such as lithium, to achieve those gains.

Lithium- or Sodium-Ion Batteries

The components of most (Li-ion or sodium-ion [Na-ion]) batteries you use regularly include:

- Electrodes (cathode, or positive end and anode, or negative end)

- Electrolytes, which are generally liquid solutions

- A separator, which keeps electrodes and electrolytes separate and is made of metal

- A current collector, which stores the energy.

Today's Li-Ion Batteries

Tomorrow's Na-Ion Batteries

Solid-State and Flow Batteries

Tomorrow's Solid-State Batteries

Solid-state batteries use solid electrolyte solutions, which don’t need a different separator. That makes them safer because they are less prone to leakage from damage or swelling in hot temperatures.

Tomorrow's Flow Batteries

Flow batteries, which are powered by reduction-oxidation (redox) reactions, involve two different liquid electrolytes that pass ions or protons back and forth through a porous membrane. These batteries can store larger amounts of energy—as much as the size of the electrolyte cells can contain—and don’t use flammable or polluting materials.

What Are the Advantages and Challenges for Batteries?

Since their invention, batteries have come to play a crucial role in enabling wider adoption of renewables and cleaner transportation, which greatly reduce carbon emissions and reliance on fossil fuels.

Think about it: Having a place to store energy on the electric grid can allow renewables—like solar—to produce and save energy when conditions are optimal, ensuring there’s round-the-clock reliable energy on those (literal) rainy days.

Next-generation batteries are also safer (less likely to combust, for example), try to avoid using critical materials that require imports, rare minerals, or digging into the earth, and can store more energy (letting you drive further in your electric vehicle before finding a charging station, for example).

The U.S. Department of Energy (DOE) and its Advanced Materials and Manufacturing Technologies Office (AMMTO) is helping the U.S. domestic manufacturing supply chain grow to fulfill the increased demand for next-generation batteries.

Trivia Answer

By moving innovations from the research and development (R&D) stage toward the market—and ultimately your pocket, garage, or facility, AMMTO helps technology progress to meet Americans’ needs. Advanced manufacturing facilities can help the United States improve the manufacturability and scalability of these essential technologies and move us closer to the goal of achieving a net-zero-emissions economy by 2050.

Through DOE and AMMTO support, members of the industry, academia, government, and entrepreneurial sectors are reducing costs and increasing the availability and performance of next-generation batteries to meet future demand.

Instead of starting from scratch every time, manufacturers can customize and expand upon standardized tools and methods—often referred to as platform manufacturing technologies—that are designed to be flexible and adaptable, saving manufacturers time and resources.

That can also reduce the time to market for next-generation energy storage materials and devices and bridge knowledge gaps between small-scale R&D and large-scale commercial manufacturing, leading to immediate impact, increasing the commercial domestic supply of battery storage devices.

With a more robust battery manufacturing industry, not only can we accelerate the transition to a clean energy economy, but we can also create good-paying jobs for Americans.

To bring these technologies closer to reality, we need:

- Advanced tooling to manufacture components at larger volumes.

- Precise technologies to assemble battery cells and systems faster.

- Modern technologies and equipment to produce newer battery materials, components, and systems.

In addition to supporting improved manufacturing of batteries, AMMTO supports efforts to improve the actual performance (such as reliability, safety, rechargeability, and amount of energy stored) as well as the environmental sustainability of production. These advances can make them less dangerous to consumers, easier and cheaper to produce, and better adapted for emerging renewable applications that may subject them to harsh conditions, such as high temperature (like EVs), high pressure (like airplanes), or smaller containers (like smart watches or pacemakers).

And we’re doing all this on home soil. As the United States works to improve energy independence and security, we need strong domestic manufacturing capabilities. That means adjusting processes and technologies within manufacturing facilities to keep up with new materials, battery designs, and growing needs.

Get Involved!

Learn more about the opportunities we’re supporting to bring next-generation batteries to the forefront.

Follow AMMTO

Catch up on AMMTO's other areas of research, news, success stories.

Sign up to receive monthly issues of the Manufacturing Moment and other updates from AMMTO on next-generation batteries and more.

-

Up to $12.5 million funding available to accelerate the establishment of circular supply chains for energy materials and products.

Up to $12.5 million funding available to accelerate the establishment of circular supply chains for energy materials and products. -

The U.S. Department of Energy’s (DOE) Advanced Materials and Manufacturing Technologies Office (AMMTO) released a request for information (RFI) to solicit feedback from stakeholders on AMMTO’s Wide Bandgap Power Electronics Strategic Framework draft.

The U.S. Department of Energy’s (DOE) Advanced Materials and Manufacturing Technologies Office (AMMTO) released a request for information (RFI) to solicit feedback from stakeholders on AMMTO’s Wide Bandgap Power Electronics Strategic Framework draft. -

AMMTO released a request for information (RFI) to gather input on its draft harsh environment materials (HEM) research, development, and demonstration landscape document.

AMMTO released a request for information (RFI) to gather input on its draft harsh environment materials (HEM) research, development, and demonstration landscape document. -

CONCEPT Phase Applications are now open in three tracks focused on clean energy, manufacturing, and transportation projects

CONCEPT Phase Applications are now open in three tracks focused on clean energy, manufacturing, and transportation projects -

Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors.

Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors. -

Information will help inform the EES2 Initiative and associated roadmap.

Information will help inform the EES2 Initiative and associated roadmap. -

Draft framework identifies opportunities and challenges to use circularity to decarbonize industry, secure supply chains, benefit communities, and create jobs.

Draft framework identifies opportunities and challenges to use circularity to decarbonize industry, secure supply chains, benefit communities, and create jobs. -

Small Businesses Receive AMMTO Funding to Advance Innovative Manufacturing and Material TechnologiesEach of the companies will receive approximately $1.15 million for Phase II SBIR awards.

Small Businesses Receive AMMTO Funding to Advance Innovative Manufacturing and Material TechnologiesEach of the companies will receive approximately $1.15 million for Phase II SBIR awards. -

In the latest round of cohorts in its Lab-Embedded Entrepreneurship Program (LEEP), 33 innovators will be embedded across four U.S. national laboratories to work with an extensive network of mentors and experts.

In the latest round of cohorts in its Lab-Embedded Entrepreneurship Program (LEEP), 33 innovators will be embedded across four U.S. national laboratories to work with an extensive network of mentors and experts. -

More than 60 organizations have committed to making semiconductor applications, including data centers, more energy efficient.

More than 60 organizations have committed to making semiconductor applications, including data centers, more energy efficient.