Seven small businesses across seven states will receive approximately $200,000 to take innovative manufacturing technologies and materials to the next level.

Advanced Materials & Manufacturing Technologies Office

July 19, 2024The U.S. Department of Energy’s (DOE) Advanced Materials and Manufacturing Technologies Office (AMMTO) today announced funding for seven small businesses across seven states to take innovative manufacturing technologies and materials to the next level as part of DOE’s Small Business Innovative Research (SBIR) and Small Business Technology Transfer (STTR) programs. Each of the companies will receive approximately $200,000 for Phase I Release II SBIR Awards. Overall, $52 million was awarded for this current round of awards to small businesses across DOE to pursue scientific, clean energy, and climate research, development, and demonstration (RD&D) projects.

DOE’s SBIR and STTR awards strive to transform DOE-supported science and technology breakthroughs into viable products and services. Small businesses that demonstrated technical feasibility for innovations during their Phase I grants will compete for funding to develop prototypes or processes during Phase II.

The AMMTO-funded SBIR Phase I Release 2 projects include:

Tiptek, LLC, West Chester, Pennsylvania (STTR)

Tiptek’s innovation enables atomically precise manufacturing of low-defect qubits (atomically precise quantum hardware) for quantum computing. Quantum computers promise to carry out calculations with quantum bits (called qubits) that use less than one thousandth the energy of today’s computers for quantum calculations of atomic structure. This project will overcome one of the key challenges of how to make this technology reliably and reproducibly by enabling the atomic precision and self-sharpening of the tips used for manufacturing the qubits. Meanwhile it also supports U.S. competitiveness by improving tips for research and quality control in today’s nonquantum semiconductor industry.

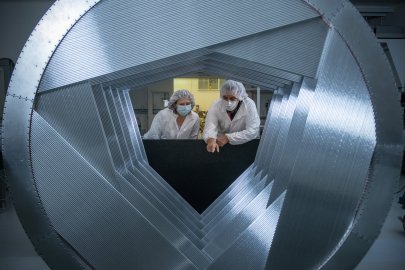

Zyvex Labs, Richardson, Texas (SBIR)

Zyvex Labs’ innovation enables the scale-up of atomically precise qubit manufacturing from current two-dimensional architecture to the three-dimensional architectures needed to make low-defect quantum circuits for quantum computing. If large-scale quantum computers can be successfully developed, they will allow quantum calculations to be made using less energy by a factor of more than 1,000 compared to what is currently possible.

Vuronyx Technologies, Arlington, Massachusetts (SBIR)

Vuronyx Technologies will develop cost-effective approaches to manufacture high-purity MAX powders. This innovation will improve manufacturing for a new class of materials that can withstand extremely harsh service conditions needed for energy applications including components for industrial, wind energy, solar power, and nuclear power industries. By improving the purity, size, and sphericity of the powder particles that are the feedstock for certain types of MAX materials, this project will improve metal powder manufacturing processes in America by streamlining a key step to their commercialization.

NanoSonic, Inc., Pembroke, Virginia (SBIR)

NanoSonic will develop an alternative procedure for the synthesis of at least four unique MAX phase powders based on molten-salt-shielded synthesis (using a molten salt bath, rather than expensive inert gas, to provide a protective environment during the synthesis process). NanoSonic will demonstrate scalability by optimizing large-scale reactions to produce high-purity material for at least two unique MAX phases and continue to reduce synthesis cost through use of recycled feedstock material. Because these structures could be used in key parts of the solar, wind, and nuclear power industries, scaling America’s ability to manufacture these materials is imperative to the nation’s transition to a clean energy economy.

Eskra Technical Products, Inc., Saukville, Wisconsin (SBIR)

Eskra’s battery manufacturing technology enables fabrication of microbatteries in irregular and conformal shapes. Expanding the number of reliable microscale manufacturing processes is critical to AMMTO’s goal to develop platform manufacturing technologies. This project will improve safety and functioning of sensors in general and vehicles in particular and is in alignment with AMMTO’s work to improve U.S. competitiveness in battery manufacturing.

Storagenergy Technologies, Inc., Salt Lake City, Utah (SBIR)

Although lithium metal is used extensively throughout various industries because of its distinctive properties, current processes of lithium metal production consume substantial amounts of electric energy and create toxic chlorine gas emissions. Storagenergy’s innovative technology for scalable electroextraction of lithium metal production is eco-friendly, saves energy, operates at a high rate, and minimizes waste generation.

Chemelectronics LLC, Los Angeles, California (SBIR)

Chemelectronics process is a major innovation in the manufacturing of lithium metal for batteries. It uses a low-temperature hydrogen plasma reduction and thermal decomposition of lithium hydride to greatly increase efficiency of lithium metal production. This innovation will yield high energy efficiency at a low cost. It also does not generate carbon emission or toxic byproducts.

The SBIR program was created by Congress to leverage small businesses to advance innovation at federal agencies. For more information about DOE’s SBIR and STTR programs, and the projects announced today, visit the Office of Science’s SBIR website. To learn more about DOE’s important work in materials and manufacturing innovation, visit the AMMTO homepage.

AMMTO News

-

Up to $12.5 million funding available to accelerate the establishment of circular supply chains for energy materials and products.

Up to $12.5 million funding available to accelerate the establishment of circular supply chains for energy materials and products. -

The U.S. Department of Energy’s (DOE) Advanced Materials and Manufacturing Technologies Office (AMMTO) released a request for information (RFI) to solicit feedback from stakeholders on AMMTO’s Wide Bandgap Power Electronics Strategic Framework draft.

The U.S. Department of Energy’s (DOE) Advanced Materials and Manufacturing Technologies Office (AMMTO) released a request for information (RFI) to solicit feedback from stakeholders on AMMTO’s Wide Bandgap Power Electronics Strategic Framework draft. -

AMMTO released a request for information (RFI) to gather input on its draft harsh environment materials (HEM) research, development, and demonstration landscape document.

AMMTO released a request for information (RFI) to gather input on its draft harsh environment materials (HEM) research, development, and demonstration landscape document. -

CONCEPT Phase Applications are now open in three tracks focused on clean energy, manufacturing, and transportation projects

CONCEPT Phase Applications are now open in three tracks focused on clean energy, manufacturing, and transportation projects -

Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors.

Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors. -

Information will help inform the EES2 Initiative and associated roadmap.

Information will help inform the EES2 Initiative and associated roadmap. -

Draft framework identifies opportunities and challenges to use circularity to decarbonize industry, secure supply chains, benefit communities, and create jobs.

Draft framework identifies opportunities and challenges to use circularity to decarbonize industry, secure supply chains, benefit communities, and create jobs. -

Small Businesses Receive AMMTO Funding to Advance Innovative Manufacturing and Material TechnologiesEach of the companies will receive approximately $1.15 million for Phase II SBIR awards.

Small Businesses Receive AMMTO Funding to Advance Innovative Manufacturing and Material TechnologiesEach of the companies will receive approximately $1.15 million for Phase II SBIR awards. -

In the latest round of cohorts in its Lab-Embedded Entrepreneurship Program (LEEP), 33 innovators will be embedded across four U.S. national laboratories to work with an extensive network of mentors and experts.

In the latest round of cohorts in its Lab-Embedded Entrepreneurship Program (LEEP), 33 innovators will be embedded across four U.S. national laboratories to work with an extensive network of mentors and experts. -

More than 60 organizations have committed to making semiconductor applications, including data centers, more energy efficient.

More than 60 organizations have committed to making semiconductor applications, including data centers, more energy efficient.

Subscribe to The Manufacturing Moment, AMMTO's monthly newsletter.